Mylar offers superior reflectivity compared to standard metallized PET due to its highly smooth surface and enhanced metal coating process, which efficiently reflects up to 98% of light and infrared radiation. Metallized PET reflects less light, generally around 85-90%, because its metal layer is thinner and less uniform, resulting in lower reflectivity across the visible and infrared spectrum. Choosing Mylar ensures optimal light and heat reflection for applications requiring maximum efficiency.

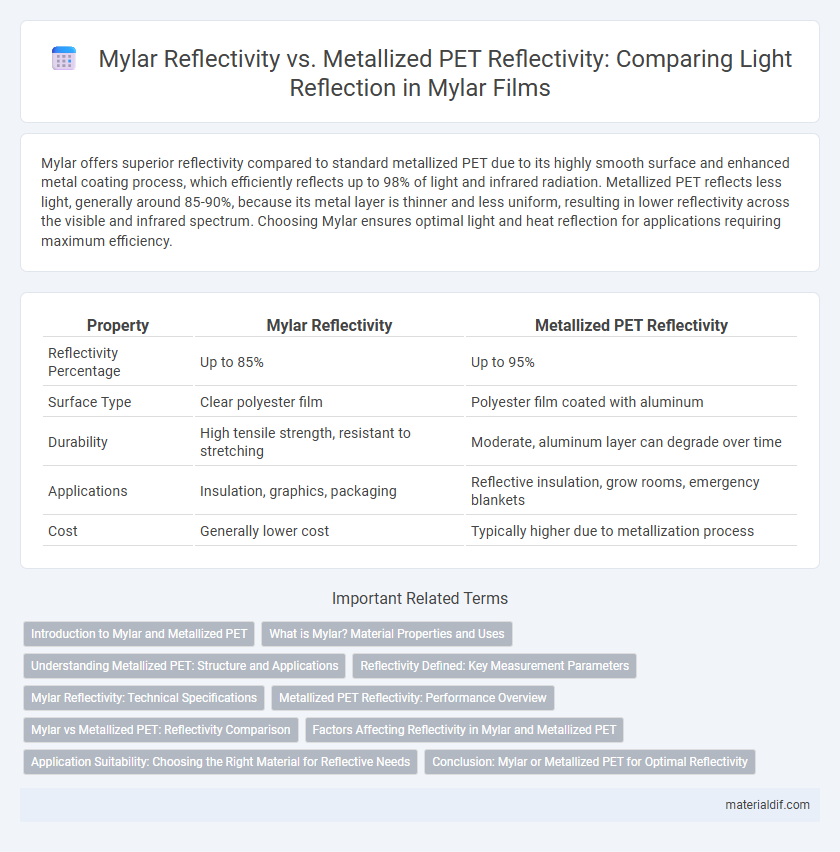

Table of Comparison

| Property | Mylar Reflectivity | Metallized PET Reflectivity |

|---|---|---|

| Reflectivity Percentage | Up to 85% | Up to 95% |

| Surface Type | Clear polyester film | Polyester film coated with aluminum |

| Durability | High tensile strength, resistant to stretching | Moderate, aluminum layer can degrade over time |

| Applications | Insulation, graphics, packaging | Reflective insulation, grow rooms, emergency blankets |

| Cost | Generally lower cost | Typically higher due to metallization process |

Introduction to Mylar and Metallized PET

Mylar, a brand of biaxially oriented polyethylene terephthalate (BoPET), features a reflective polyester film prized for its high tensile strength and chemical stability. Metallized PET, a variant of Mylar, is coated with a thin layer of metal, typically aluminum, to enhance reflectivity, achieving reflectance levels up to 90-95%, making it ideal for insulation and light management applications. The base Mylar film without metallization offers lower reflectivity but provides superior durability and clarity for applications requiring light diffusion rather than maximum reflection.

What is Mylar? Material Properties and Uses

Mylar, a brand name for biaxially-oriented polyethylene terephthalate (BoPET), offers high tensile strength, chemical stability, and excellent reflectivity, making it ideal for insulation, packaging, and reflective applications. Its reflectivity typically ranges around 85-90%, while metallized PET variants improve reflectivity up to 95% by coating the Mylar base with a thin metal layer, enhancing light and heat reflection. These properties allow Mylar and metallized PET films to be widely used in solar reflectors, emergency blankets, and electronic insulation.

Understanding Metallized PET: Structure and Applications

Metallized PET consists of a polyethylene terephthalate base film coated with a thin layer of metal, typically aluminum, which enhances its reflectivity and barrier properties. This structure provides superior reflectivity compared to standard Mylar, making it ideal for applications such as insulation, packaging, and emergency blankets. The combination of metal coating and PET substrate delivers excellent durability, chemical resistance, and moisture barrier performance.

Reflectivity Defined: Key Measurement Parameters

Reflectivity is defined by key measurement parameters such as specular reflectance, total reflectance, and reflectance wavelength range. Mylar typically exhibits higher specular reflectivity due to its smooth surface and uniform polyester base, while metallized PET reflects light primarily due to the thin metal layer, influencing its overall reflectance efficiency. Precise reflectivity measurement considers angle of incidence, surface finish, and spectral response to determine the material's effectiveness in reflective applications.

Mylar Reflectivity: Technical Specifications

Mylar exhibits a high reflectivity rate of approximately 85% for visible light, making it an excellent material for reflective applications. Its polyester base offers stability and durability, with metallized coatings enhancing reflectance without compromising flexibility. Technical specifications indicate that Mylar's surface reflectance can be fine-tuned through vacuum deposition techniques, achieving consistent performance across different wavelengths.

Metallized PET Reflectivity: Performance Overview

Metallized PET (Polyethylene Terephthalate) exhibits high reflectivity due to its thin metal coating, typically aluminum, which reflects up to 95% of visible light, making it ideal for insulation and packaging applications. Its performance in thermal insulation is superior compared to non-metallized Mylar, as the metal layer effectively reduces radiant heat transfer. Metallized PET films maintain reflectivity under various environmental conditions, ensuring durability and consistent energy efficiency.

Mylar vs Metallized PET: Reflectivity Comparison

Mylar typically offers a reflectivity rate of around 60-70%, while metallized PET can achieve higher reflectivity, often exceeding 90% due to its aluminum coating. The metallized layer on PET enhances light and heat reflection compared to standard Mylar, making metallized PET a preferred choice for applications requiring maximum reflectivity. Reflectivity differences impact energy efficiency in insulation, solar reflectors, and thermal blankets where metallized PET outperforms standard Mylar films.

Factors Affecting Reflectivity in Mylar and Metallized PET

Mylar typically exhibits a high reflectivity rate of around 60-70%, whereas metallized PET films achieve reflectivity levels exceeding 90% due to the thin metal coating, usually aluminum. Factors affecting reflectivity in Mylar and metallized PET include surface smoothness, metal layer thickness, and material purity, which influence light absorption and scattering. Environmental conditions such as temperature and humidity can also degrade reflective properties over time, impacting performance in applications like insulation and solar reflectors.

Application Suitability: Choosing the Right Material for Reflective Needs

Mylar offers a high reflectivity rate of up to 92-98%, making it ideal for applications requiring maximum light reflection and durability, such as grow rooms and emergency blankets. Metallized PET typically reflects around 85-90%, providing cost-effective solutions for decorative uses and packaging but may degrade faster under UV exposure. Selecting between Mylar and metallized PET depends on the specific reflective efficiency, environmental exposure, and longevity needed for the application.

Conclusion: Mylar or Metallized PET for Optimal Reflectivity

Mylar exhibits a high reflectivity rate of approximately 92%, making it an excellent choice for applications requiring efficient light reflection. Metallized PET typically offers slightly higher reflectivity, reaching up to 95%, due to its thin metal coating that enhances light reflection and durability. For optimal reflectivity, Metallized PET is preferable in scenarios demanding maximum brightness and longevity, while Mylar suits cost-sensitive uses requiring good reflective performance.

Mylar Reflectivity vs Metallized PET Reflectivity Infographic

materialdif.com

materialdif.com