Mylar laminating offers superior durability and water resistance compared to thermal laminating, making it ideal for long-term document protection. Thermal laminating uses heat to bond layers quickly but may cause curling or damage to heat-sensitive materials. Choosing between Mylar and thermal laminating depends on the need for strength, clarity, and preservation of the item being laminated.

Table of Comparison

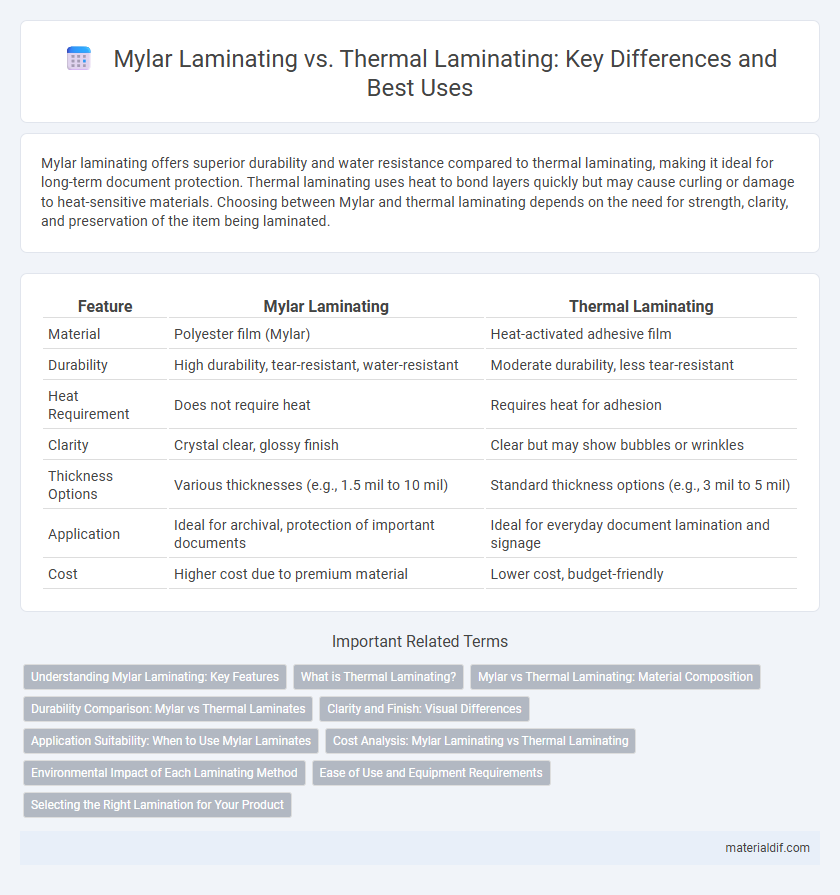

| Feature | Mylar Laminating | Thermal Laminating |

|---|---|---|

| Material | Polyester film (Mylar) | Heat-activated adhesive film |

| Durability | High durability, tear-resistant, water-resistant | Moderate durability, less tear-resistant |

| Heat Requirement | Does not require heat | Requires heat for adhesion |

| Clarity | Crystal clear, glossy finish | Clear but may show bubbles or wrinkles |

| Thickness Options | Various thicknesses (e.g., 1.5 mil to 10 mil) | Standard thickness options (e.g., 3 mil to 5 mil) |

| Application | Ideal for archival, protection of important documents | Ideal for everyday document lamination and signage |

| Cost | Higher cost due to premium material | Lower cost, budget-friendly |

Understanding Mylar Laminating: Key Features

Mylar laminating utilizes a polyester film known for its durability, clarity, and resistance to moisture and chemicals, making it ideal for long-lasting protection of documents and artworks. Unlike thermal laminating, which relies on heat-activated adhesive to bond the laminate, Mylar laminating often involves pressure-sensitive or solvent-based adhesives that provide superior structural integrity and archival quality. Key features of Mylar laminating include exceptional dimensional stability, UV resistance, and the ability to preserve color vibrancy over time, crucial for high-value or frequently handled materials.

What is Thermal Laminating?

Thermal laminating uses heat-activated adhesive films, such as Mylar, to bond a protective layer onto documents or materials, ensuring durability and moisture resistance. This method offers a smooth, clear finish that enhances print quality without the need for additional glues or sprays. Compatible with various laminating machines, thermal laminating efficiently seals items to prevent damage from wear, tear, and environmental factors.

Mylar vs Thermal Laminating: Material Composition

Mylar laminating uses biaxially-oriented polyethylene terephthalate (BoPET), a durable polyester film known for its strength, clarity, and resistance to heat and chemicals. Thermal laminating employs heat-activated adhesives typically applied to a plastics film such as polypropylene or polyester, which bonds to documents when heat and pressure are applied. The key difference lies in Mylar's inherent film properties providing superior dimensional stability and longevity, whereas thermal laminating relies on adhesive bonding for protection.

Durability Comparison: Mylar vs Thermal Laminates

Mylar laminating offers superior durability compared to traditional thermal laminates due to its polyester composition, which provides excellent resistance to tearing, moisture, and UV exposure. Thermal laminating films, often made from lower-grade plastics, may degrade faster under frequent handling or environmental stress. Choosing Mylar ensures longer-lasting protection for documents, signs, and artworks in demanding conditions.

Clarity and Finish: Visual Differences

Mylar laminating provides superior clarity and a smooth, glossy finish compared to traditional thermal laminating, which can sometimes result in slight cloudiness or uneven texture. The polyester film in Mylar enhances sharpness and color vibrancy, making images and text stand out more distinctly. Thermal laminating, while effective for protection, often produces a less polished appearance, impacting the overall visual quality of laminated materials.

Application Suitability: When to Use Mylar Laminates

Mylar laminates excel in applications requiring exceptional clarity, durability, and moisture resistance, making them ideal for preserving photographs, documents, and archival materials. Thermal laminating is more suitable for quick, cost-effective lamination of everyday items like menus, ID cards, and instructional materials. Choose Mylar laminates when long-term protection and high-quality transparency are critical for safeguarding valuable, frequently handled documents.

Cost Analysis: Mylar Laminating vs Thermal Laminating

Mylar laminating typically incurs higher upfront equipment costs compared to thermal laminating, but offers superior durability and resistance to heat and moisture, making it cost-effective for long-term use. Thermal laminating requires lower initial investment and faster processing, yet may lead to increased replacement expenses due to less robust protection. Evaluating total cost of ownership reveals Mylar laminating is more economical for archival and high-quality applications, while thermal laminating suits budget-conscious, short-term projects.

Environmental Impact of Each Laminating Method

Mylar laminating uses polyester film known for its durability and recyclability, reducing waste in the long term compared to traditional thermal laminating which often employs non-recyclable plastic films. Thermal laminating consumes more energy due to heat activation, increasing its carbon footprint relative to cold Mylar laminating methods. Choosing Mylar laminating can enhance sustainability by minimizing harmful emissions and facilitating easier recycling processes.

Ease of Use and Equipment Requirements

Mylar laminating typically requires specialized equipment designed to handle the thicker, more durable Mylar films, ensuring a smooth finish but often demanding higher initial investment and setup time. Thermal laminating uses heat-sensitive adhesive films that work with more common, less costly machines, making it easier to operate for everyday office or home use without extensive training. The choice between Mylar and thermal laminating hinges on balancing the need for professional-grade durability against user-friendly, accessible equipment options.

Selecting the Right Lamination for Your Product

Mylar laminating offers superior clarity, durability, and chemical resistance compared to thermal laminating, making it ideal for high-quality product preservation and protection. Thermal laminating uses a heat-sensitive adhesive film that seals quickly but may not provide the same longevity or resistance to environmental factors as Mylar. Selecting the right lamination depends on product use, desired durability, and exposure conditions, with Mylar preferred for archival and heavy-duty applications.

Mylar Laminating vs Thermal Laminating Infographic

materialdif.com

materialdif.com