Mylar laminate offers superior durability and moisture resistance compared to vinyl laminate, making it ideal for heavy-duty pet applications. It provides a glossy, reflective finish that enhances visual appeal while maintaining flexibility and tear resistance. Vinyl laminate, while more cost-effective, tends to be less durable and is better suited for short-term or decorative pet products.

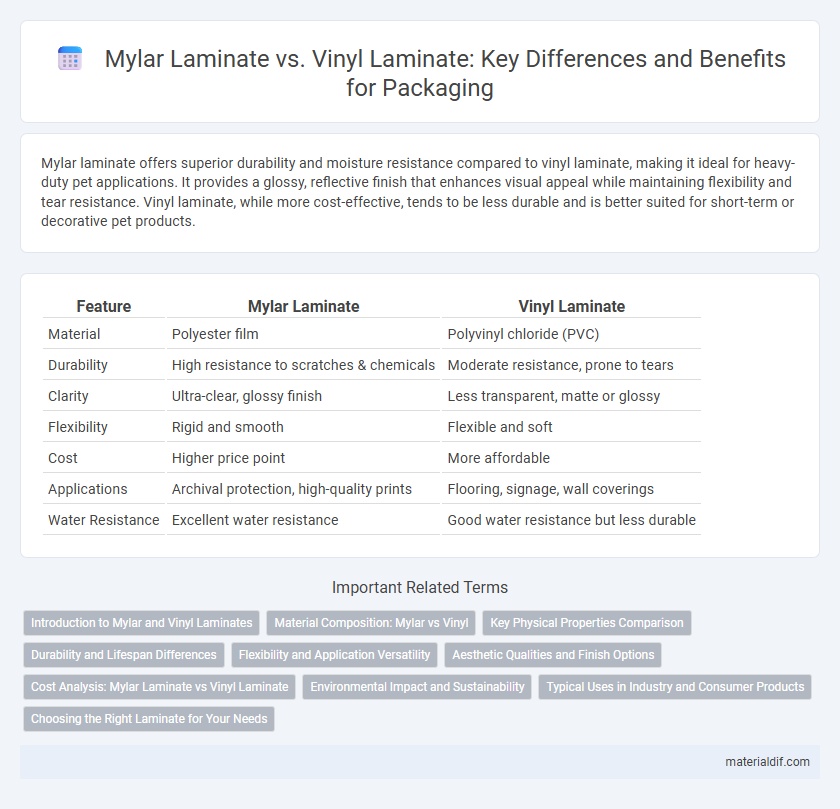

Table of Comparison

| Feature | Mylar Laminate | Vinyl Laminate |

|---|---|---|

| Material | Polyester film | Polyvinyl chloride (PVC) |

| Durability | High resistance to scratches & chemicals | Moderate resistance, prone to tears |

| Clarity | Ultra-clear, glossy finish | Less transparent, matte or glossy |

| Flexibility | Rigid and smooth | Flexible and soft |

| Cost | Higher price point | More affordable |

| Applications | Archival protection, high-quality prints | Flooring, signage, wall coverings |

| Water Resistance | Excellent water resistance | Good water resistance but less durable |

Introduction to Mylar and Vinyl Laminates

Mylar laminate utilizes polyester film known for its durability, clarity, and resistance to moisture and chemicals, making it ideal for protective coatings and packaging. Vinyl laminate, composed of polyvinyl chloride (PVC), offers flexibility, strong adhesion, and excellent resistance to abrasion and weathering, frequently used in signage and decorative applications. Both laminates enhance surface protection but differ fundamentally in material composition and specific performance characteristics.

Material Composition: Mylar vs Vinyl

Mylar laminate is made from stretched polyethylene terephthalate (PET), offering high durability, chemical resistance, and excellent clarity. Vinyl laminate consists of polyvinyl chloride (PVC), which provides greater flexibility and waterproof characteristics but may lack the tensile strength of Mylar. The distinct polymer structures in Mylar and vinyl result in significant differences in surface toughness, clarity, and environmental resistance.

Key Physical Properties Comparison

Mylar laminate exhibits superior tensile strength, enhanced chemical resistance, and greater dimensional stability compared to vinyl laminate, making it ideal for applications requiring durability and longevity. Vinyl laminate offers increased flexibility and impact resistance but may degrade under prolonged exposure to UV light and harsh chemicals. Both materials provide excellent surface protection, yet Mylar's superior clarity and thermal resistance position it as the preferred choice for high-performance laminations.

Durability and Lifespan Differences

Mylar laminate offers superior durability due to its resistance to tearing, moisture, and UV damage, making it ideal for long-term protection in harsh environments. Vinyl laminate, while also durable, is more prone to scratches and may degrade faster when exposed to direct sunlight and heavy wear. The lifespan of Mylar laminate typically exceeds vinyl by several years, providing enhanced preservation for documents, artwork, and packaging materials.

Flexibility and Application Versatility

Mylar laminate offers superior flexibility compared to vinyl laminate, making it ideal for applications requiring frequent bending or shaping. Its high tensile strength and resistance to tearing enhance durability in flexible packaging, electronics, and graphic overlays. Vinyl laminate, while more rigid, suits applications needing firm structure, but lacks Mylar's adaptability across diverse industries.

Aesthetic Qualities and Finish Options

Mylar laminate offers a highly reflective, glossy finish that enhances colors with vibrant clarity, making it ideal for premium visual appeal. Vinyl laminate provides a wider range of textures, including matte, satin, and gloss, allowing for versatile aesthetic customization tailored to different design preferences. Both materials protect surfaces effectively, but Mylar's smooth, glass-like finish contrasts with vinyl's tactile options, influencing final product look and feel.

Cost Analysis: Mylar Laminate vs Vinyl Laminate

Mylar laminate generally offers a higher initial cost compared to vinyl laminate due to its superior clarity and durability, making it a preferred choice for premium protection and presentation. Vinyl laminate provides a more budget-friendly option with reasonable protection, suitable for less demanding applications where cost efficiency is prioritized. When evaluating long-term value, Mylar's resistance to moisture, UV light, and wear often results in lower replacement and maintenance expenses compared to vinyl laminate.

Environmental Impact and Sustainability

Mylar laminate offers superior environmental benefits compared to vinyl laminate due to its recyclability and lower production emissions, reducing overall carbon footprint. Vinyl laminate is often derived from PVC, which releases harmful toxins during manufacturing and disposal, posing significant environmental hazards. Opting for Mylar laminate supports sustainability efforts by minimizing plastic pollution and promoting eco-friendly material lifecycle management.

Typical Uses in Industry and Consumer Products

Mylar laminate is widely used in the electronics industry for insulation, packaging, and decorative purposes due to its high tensile strength and excellent barrier properties. Vinyl laminate, favored in automotive and flooring applications, offers superior flexibility, abrasion resistance, and easier adhesion for surface finishing. Consumer products such as protective sleeves, labels, and decals frequently utilize Mylar for durability and clarity, while vinyl laminates are common in wall coverings and upholstery for their versatility and aesthetic appeal.

Choosing the Right Laminate for Your Needs

Mylar laminate offers superior clarity, chemical resistance, and durability, making it ideal for applications requiring long-term protection and high transparency, such as archival documents and electronic displays. Vinyl laminate provides greater flexibility and impact resistance, suitable for surfaces subject to frequent handling or abrasion, including book covers and signage. Selecting the right laminate depends on your specific needs for clarity, durability, and environmental exposure.

Mylar Laminate vs Vinyl Laminate Infographic

materialdif.com

materialdif.com