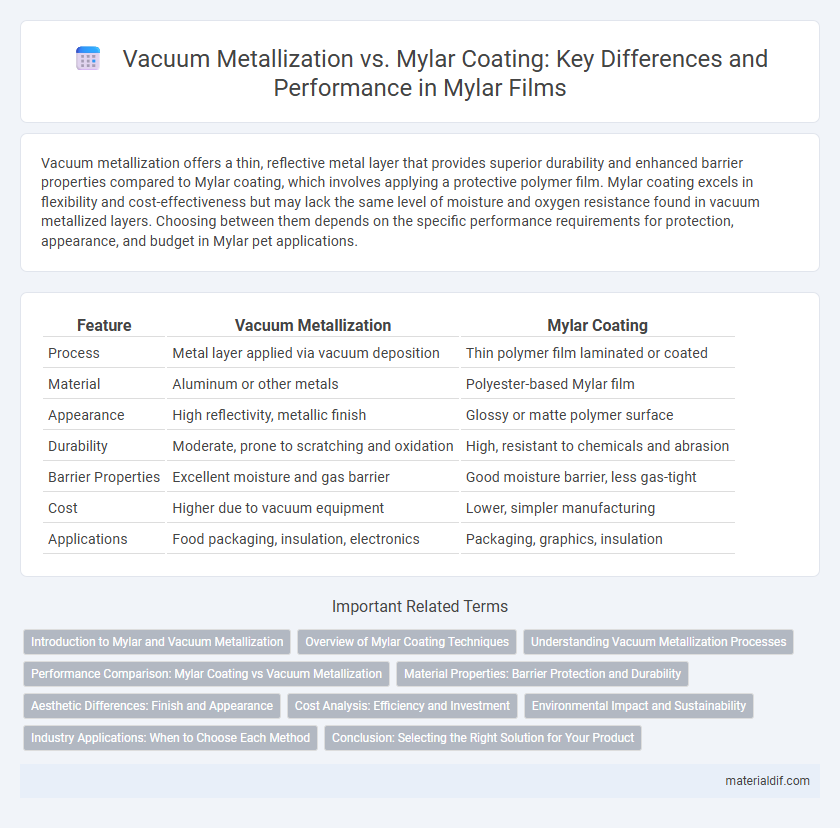

Vacuum metallization offers a thin, reflective metal layer that provides superior durability and enhanced barrier properties compared to Mylar coating, which involves applying a protective polymer film. Mylar coating excels in flexibility and cost-effectiveness but may lack the same level of moisture and oxygen resistance found in vacuum metallized layers. Choosing between them depends on the specific performance requirements for protection, appearance, and budget in Mylar pet applications.

Table of Comparison

| Feature | Vacuum Metallization | Mylar Coating |

|---|---|---|

| Process | Metal layer applied via vacuum deposition | Thin polymer film laminated or coated |

| Material | Aluminum or other metals | Polyester-based Mylar film |

| Appearance | High reflectivity, metallic finish | Glossy or matte polymer surface |

| Durability | Moderate, prone to scratching and oxidation | High, resistant to chemicals and abrasion |

| Barrier Properties | Excellent moisture and gas barrier | Good moisture barrier, less gas-tight |

| Cost | Higher due to vacuum equipment | Lower, simpler manufacturing |

| Applications | Food packaging, insulation, electronics | Packaging, graphics, insulation |

Introduction to Mylar and Vacuum Metallization

Mylar, a polyester film known for its durability, clarity, and barrier properties, serves as a versatile substrate in various industrial applications. Vacuum metallization involves depositing a thin layer of metal, typically aluminum, onto Mylar through a vapor deposition process, enhancing its reflective and barrier qualities. This metallized Mylar film is widely used in packaging, insulation, and decorative purposes due to its improved moisture resistance and tensile strength.

Overview of Mylar Coating Techniques

Mylar coating techniques primarily involve vacuum metallization, chemical vapor deposition, and sputtering, each enhancing the film's barrier, reflectivity, and durability properties. Vacuum metallization deposits a thin metallic layer onto Mylar by vaporizing metal in a vacuum chamber, creating a highly reflective, moisture-resistant surface ideal for packaging and insulation. Chemical vapor deposition and sputtering offer alternative methods to apply uniform coatings that improve the Mylar film's performance in electronic and optical applications.

Understanding Vacuum Metallization Processes

Vacuum metallization involves depositing a thin metal layer onto a Mylar film under high vacuum conditions, enhancing its reflective and barrier properties without adding significant weight. This process improves optical clarity and electrical conductivity while maintaining the film's flexibility and strength. By controlling vaporized metal deposition, vacuum metallization achieves uniform coatings crucial for applications in insulation, packaging, and electronics.

Performance Comparison: Mylar Coating vs Vacuum Metallization

Mylar coating offers superior flexibility and chemical resistance compared to vacuum metallization, which provides a more reflective and conductive finish ideal for applications requiring high thermal insulation and electrical conductivity. Vacuum metallized Mylar excels in barrier properties and durability under harsh environmental conditions, while Mylar coating ensures better mechanical strength and moisture resistance. Performance differences hinge on specific use cases, with vacuum metallization preferred for solar control films and electronics, whereas Mylar coating is favored for packaging and decorative applications.

Material Properties: Barrier Protection and Durability

Vacuum metallization enhances Mylar by depositing a thin metal layer that significantly improves barrier protection against moisture, oxygen, and light, increasing shelf life for sensitive products. Mylar coating, typically involving polymer layers, offers improved durability and resistance to abrasion, chemicals, and heat, ensuring mechanical strength and flexibility. The combination of vacuum metallization with Mylar coatings optimizes both barrier properties and physical durability, making it ideal for packaging and insulation applications.

Aesthetic Differences: Finish and Appearance

Vacuum metallization on Mylar produces a highly reflective, mirror-like finish that enhances brightness and metallic luster, ideal for packaging and decorative applications requiring vivid visual impact. Mylar coating typically results in a softer, matte or satin finish that diffuses light, offering subtle elegance and reduced glare suitable for premium labels and graphic overlays. The choice between vacuum metallization and Mylar coating significantly affects the aesthetic expression, with vacuum metallization emphasizing shine and brilliance, while Mylar coatings prioritize texture and muted optics.

Cost Analysis: Efficiency and Investment

Vacuum metallization typically demands higher initial investment due to specialized equipment and energy-intensive processes, whereas Mylar coating offers a cost-efficient alternative with lower operational expenses and rapid production cycles. The efficiency of Mylar coating lies in its scalable application methods that reduce material waste and energy consumption, optimizing overall cost-effectiveness for large volume manufacturing. An informed cost analysis reveals that while vacuum metallization delivers superior reflectivity and durability, Mylar coating provides a strategic balance of performance and affordability for budget-sensitive projects.

Environmental Impact and Sustainability

Vacuum metallization and Mylar coating differ significantly in environmental impact and sustainability, with Mylar, a type of polyester film, offering better recyclability and lower emissions during production. Vacuum metallization involves vaporizing metals like aluminum, consuming more energy and generating hazardous waste, which raises concerns over its ecological footprint. Opting for Mylar coatings improves sustainability through reduced resource consumption and enhanced material reuse in packaging and insulation applications.

Industry Applications: When to Choose Each Method

Vacuum metallization is ideal for industries requiring thin, uniform metallic films on Mylar, such as electronics, packaging, and decorative applications due to its precise control and reflective qualities. Mylar coating suits applications demanding enhanced durability, chemical resistance, or barrier properties, common in aerospace, automotive, and food packaging industries. Selecting between vacuum metallization and Mylar coating depends on desired functional properties like conductivity, moisture barrier, and aesthetic finish in specific industrial uses.

Conclusion: Selecting the Right Solution for Your Product

Vacuum metallization offers a durable, reflective metal layer ideal for high-end packaging and insulation, while Mylar coating provides a flexible, lightweight barrier with excellent moisture and chemical resistance. Choosing between vacuum metallization and Mylar coating depends on product requirements such as durability, visual appeal, and environmental exposure. For optimal performance and cost-efficiency, integrate product-specific factors like shelf life, application method, and desired physical properties into the decision-making process.

Vacuum Metallization vs Mylar Coating Infographic

materialdif.com

materialdif.com