Mylar coating provides a durable, reflective surface that enhances moisture resistance and extends the lifespan of pet products. Lamination adds a protective layer but often lacks the same level of flexibility and clarity found in Mylar coatings. Choosing between the two depends on the desired balance of durability, appearance, and cost for your pet's needs.

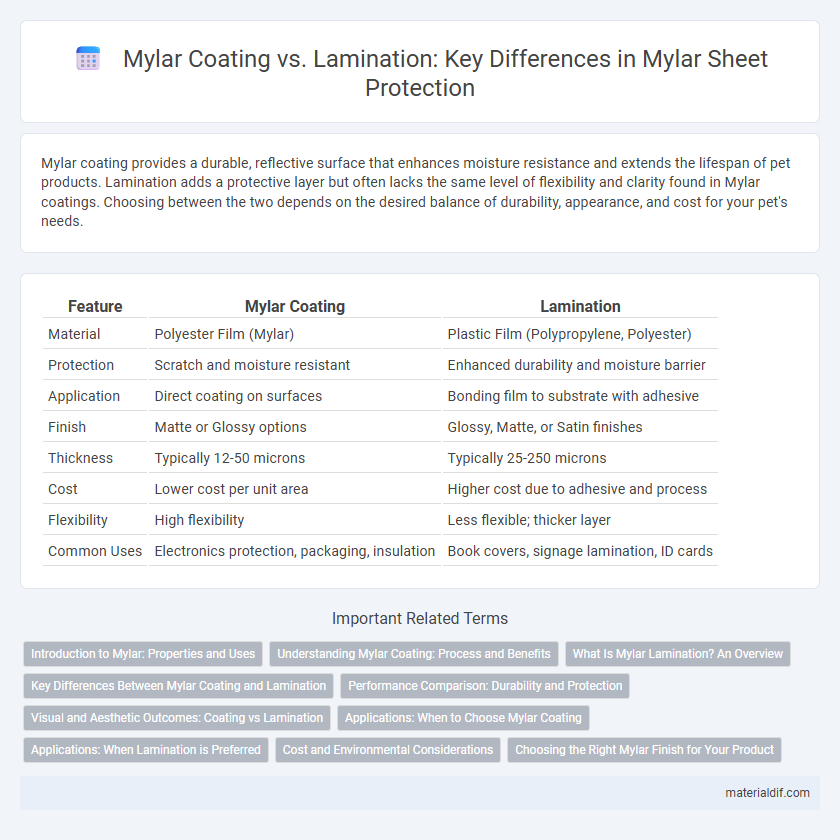

Table of Comparison

| Feature | Mylar Coating | Lamination |

|---|---|---|

| Material | Polyester Film (Mylar) | Plastic Film (Polypropylene, Polyester) |

| Protection | Scratch and moisture resistant | Enhanced durability and moisture barrier |

| Application | Direct coating on surfaces | Bonding film to substrate with adhesive |

| Finish | Matte or Glossy options | Glossy, Matte, or Satin finishes |

| Thickness | Typically 12-50 microns | Typically 25-250 microns |

| Cost | Lower cost per unit area | Higher cost due to adhesive and process |

| Flexibility | High flexibility | Less flexible; thicker layer |

| Common Uses | Electronics protection, packaging, insulation | Book covers, signage lamination, ID cards |

Introduction to Mylar: Properties and Uses

Mylar, a polyester film known for its exceptional tensile strength, chemical stability, and barrier properties, is widely used in coatings and laminations to enhance durability and moisture resistance. Mylar coating involves applying a thin protective layer directly onto surfaces, improving scratch resistance and flexibility, while lamination sandwiches Mylar between layers for enhanced structural integrity and insulation. These properties make Mylar essential in electronics, packaging, and insulation industries where durability and protection from environmental factors are critical.

Understanding Mylar Coating: Process and Benefits

Mylar coating involves applying a thin, transparent layer of polyester film onto surfaces to enhance durability, moisture resistance, and clarity, often used in packaging and electronics. This process creates a protective barrier that preserves the integrity of printed materials and improves scratch resistance without adding significant bulk. Compared to lamination, Mylar coating maintains flexibility and allows for better adhesion to substrates, making it ideal for applications requiring high transparency and lightweight protection.

What Is Mylar Lamination? An Overview

Mylar lamination involves applying a thin polyester film over printed materials to enhance durability, moisture resistance, and visual clarity. This protective layer prevents fading, tearing, and damage from environmental factors, making it ideal for preserving documents, photos, and artwork. Compared to Mylar coating, lamination provides a thicker, more rigid finish that significantly extends the lifespan of the laminated items.

Key Differences Between Mylar Coating and Lamination

Mylar coating involves applying a thin polyester film directly onto a surface to enhance durability, water resistance, and clarity, whereas lamination typically encases a document or item with a protective plastic film sealed on all edges. Mylar coatings preserve flexibility and allow for targeted application, making them ideal for electronic displays and packaging, while lamination provides a rigid barrier against physical damage and moisture, often used for ID cards and posters. The key difference lies in Mylar coating's thin, conformal layer versus lamination's fully encapsulating film, affecting both the product's texture and protective capabilities.

Performance Comparison: Durability and Protection

Mylar coating offers enhanced durability through a thin, protective layer that resists scratches, moisture, and UV damage, maintaining clarity and strength over time. Lamination provides a thicker, more robust barrier that shields against physical damage, abrasion, and extended exposure to environmental elements, often improving rigidity. Both methods enhance Mylar's protective qualities, but lamination typically delivers superior long-term protection in harsh conditions, while coating is preferred for maintaining flexibility and optical clarity.

Visual and Aesthetic Outcomes: Coating vs Lamination

Mylar coating enhances visual clarity and gloss by forming a smooth, thin protective layer that maintains the original texture and color vibrancy of the printed material. Lamination adds a thicker, durable layer that can be either matte or glossy, significantly altering the tactile experience and increasing rigidity while providing robust protection against scratches and moisture. Choosing between Mylar coating and lamination depends on desired aesthetic effects, with coating preserving fine details and lamination offering a more pronounced, high-quality finish.

Applications: When to Choose Mylar Coating

Mylar coating is ideal for applications requiring enhanced barrier properties, such as in food packaging where moisture and oxygen resistance are critical. It offers a thin, flexible protective layer that preserves freshness without significantly altering the material's weight or transparency. Choose Mylar coating for lightweight, cost-effective solutions in electronic insulation and reflective insulation where durability and clarity are essential.

Applications: When Lamination is Preferred

Mylar lamination is preferred in applications requiring enhanced durability, moisture resistance, and extended shelf life, such as packaging for food, pharmaceuticals, and electronics. It offers superior barrier properties against oxygen and contaminants compared to Mylar coating, making it ideal for sensitive products. Industries prioritize lamination when the protection of the contents and product presentation are critical factors.

Cost and Environmental Considerations

Mylar coating generally incurs lower initial costs compared to lamination, making it a cost-effective option for applications requiring moisture resistance and durability. Lamination, while more expensive, provides superior protection against physical damage and extends product lifespan, potentially reducing long-term expenses. From an environmental perspective, Mylar coatings tend to use less plastic material and produce less waste, whereas lamination often involves multiple layers that complicate recycling and increase landfill impact.

Choosing the Right Mylar Finish for Your Product

Mylar coating provides a durable protective layer that enhances resistance to moisture, chemicals, and abrasion, making it ideal for products requiring a sleek, glossy finish and increased longevity. In contrast, Mylar lamination offers a thicker barrier with superior rigidity and impact protection, suitable for packaging and items needing enhanced structural support. Selecting the right Mylar finish depends on product-specific needs such as flexibility, clarity, durability, and environmental exposure to maximize performance and aesthetic appeal.

Mylar Coating vs Lamination Infographic

materialdif.com

materialdif.com