BoPET offers superior durability and heat resistance compared to PVC, making it ideal for long-lasting Mylar pet applications. Its dimensional stability and clarity enhance the protective and aesthetic qualities of packaging, while PVC may degrade faster under environmental stress. Choosing BoPET over PVC ensures better performance and sustainability in Mylar pet products.

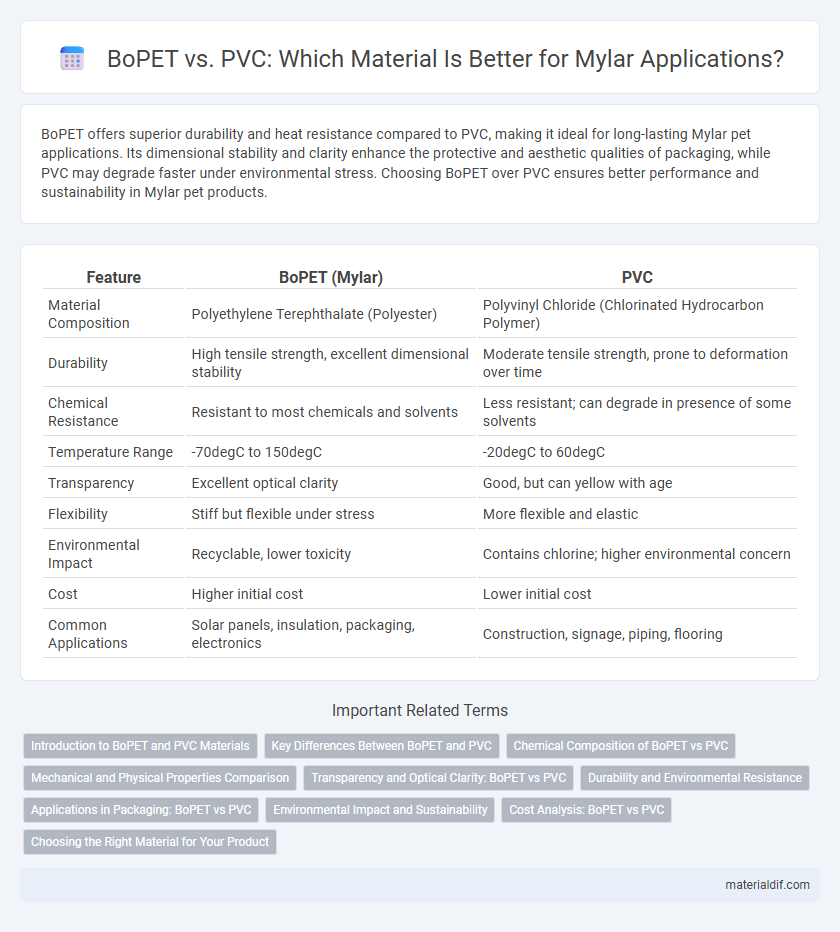

Table of Comparison

| Feature | BoPET (Mylar) | PVC |

|---|---|---|

| Material Composition | Polyethylene Terephthalate (Polyester) | Polyvinyl Chloride (Chlorinated Hydrocarbon Polymer) |

| Durability | High tensile strength, excellent dimensional stability | Moderate tensile strength, prone to deformation over time |

| Chemical Resistance | Resistant to most chemicals and solvents | Less resistant; can degrade in presence of some solvents |

| Temperature Range | -70degC to 150degC | -20degC to 60degC |

| Transparency | Excellent optical clarity | Good, but can yellow with age |

| Flexibility | Stiff but flexible under stress | More flexible and elastic |

| Environmental Impact | Recyclable, lower toxicity | Contains chlorine; higher environmental concern |

| Cost | Higher initial cost | Lower initial cost |

| Common Applications | Solar panels, insulation, packaging, electronics | Construction, signage, piping, flooring |

Introduction to BoPET and PVC Materials

BoPET (Biaxially-oriented polyethylene terephthalate) is a polyester film known for its high tensile strength, chemical resistance, and dimensional stability, making it ideal for packaging, insulation, and printed electronics. PVC (Polyvinyl chloride) is a widely used polymer characterized by its flexibility, flame resistance, and excellent electrical insulation properties, commonly applied in construction, cables, and signage. Compared to PVC, BoPET offers superior clarity, moisture barrier properties, and recyclability, influencing material choice in various industrial and commercial applications.

Key Differences Between BoPET and PVC

BoPET (Biaxially Oriented Polyethylene Terephthalate) offers superior dimensional stability and tensile strength compared to PVC (Polyvinyl Chloride), making it ideal for applications requiring durability and heat resistance. While BoPET provides excellent chemical resistance and clarity, PVC is favored for its flexibility and cost-effectiveness in insulation and packaging. Environmental impact also differs as BoPET is more recyclable, whereas PVC production involves harmful chlorine compounds affecting sustainability.

Chemical Composition of BoPET vs PVC

BoPET (Biaxially Oriented Polyethylene Terephthalate) is a polyester film derived from polyethylene terephthalate, characterized by its strong polymer chains aligned in two directions through biaxial orientation, providing excellent chemical resistance and stability. In contrast, PVC (Polyvinyl Chloride) is a vinyl polymer composed of repeating vinyl chloride monomers, which contain chlorine atoms that influence its chemical reactivity, durability, and environmental considerations. The chemical structure of BoPET offers superior resistance to solvents and UV degradation compared to PVC, making it a preferred choice in applications requiring long-term chemical and dimensional stability.

Mechanical and Physical Properties Comparison

BoPET (Biaxially Oriented Polyethylene Terephthalate) exhibits superior mechanical strength, higher tensile modulus, and greater dimensional stability compared to PVC (Polyvinyl Chloride). BoPET offers excellent resistance to tearing, stretching, and impact, maintaining performance under stress, whereas PVC tends to be more flexible but less durable over time. The thermal endurance of BoPET extends up to 150degC, outperforming PVC's lower heat resistance, making BoPET ideal for demanding industrial applications requiring durability and stability.

Transparency and Optical Clarity: BoPET vs PVC

BoPET (Biaxially Oriented Polyethylene Terephthalate) offers superior transparency and optical clarity compared to PVC (Polyvinyl Chloride), making it ideal for applications requiring high-quality visual presentation such as packaging and displays. The inherent crystalline structure of BoPET provides greater light transmittance and reduced haze, ensuring clearer and sharper images. PVC tends to have a lower optical clarity due to its amorphous nature, often resulting in a more cloudy or opaque appearance under similar conditions.

Durability and Environmental Resistance

BoPET (Biaxially Oriented Polyethylene Terephthalate) demonstrates superior durability and environmental resistance compared to PVC (Polyvinyl Chloride). BoPET offers excellent tensile strength, dimensional stability, and resistance to UV radiation, moisture, and chemical exposure, making it ideal for long-term applications. In contrast, PVC tends to degrade faster under environmental stressors, such as prolonged sunlight and temperature fluctuations, resulting in reduced lifespan and performance.

Applications in Packaging: BoPET vs PVC

BoPET (Biaxially Oriented Polyethylene Terephthalate) is widely preferred in packaging applications for its superior clarity, tensile strength, and barrier properties, making it ideal for food and pharmaceutical packaging. PVC (Polyvinyl Chloride) offers excellent flexibility and chemical resistance, commonly used in shrink wraps and blister packs but has environmental and recyclability concerns compared to BoPET. The choice between BoPET and PVC depends on specific packaging needs such as durability, transparency, and sustainability requirements.

Environmental Impact and Sustainability

BoPET (Biaxially Oriented Polyethylene Terephthalate) exhibits superior environmental sustainability compared to PVC (Polyvinyl Chloride) due to its higher recyclability and lower toxic emissions during production and disposal. PVC manufacturing releases harmful dioxins and requires additives that pose long-term environmental hazards, whereas BoPET is derived from polyester, facilitating closed-loop recycling processes with reduced ecological footprints. The durability and chemical resistance of BoPET also contribute to extended product lifespans, minimizing waste generation and supporting sustainable material cycles.

Cost Analysis: BoPET vs PVC

BoPET (Biaxially Oriented Polyethylene Terephthalate) typically incurs higher upfront costs compared to PVC (Polyvinyl Chloride) due to its advanced manufacturing process and superior durability. However, BoPET offers long-term cost benefits through enhanced resistance to moisture, chemicals, and temperature variations, reducing replacement and maintenance expenses significantly. PVC remains a cost-effective choice for short-term applications where budget constraints outweigh longevity and performance requirements.

Choosing the Right Material for Your Product

BoPET (Biaxially Oriented Polyethylene Terephthalate) offers superior clarity, chemical resistance, and dimensional stability compared to PVC, making it ideal for applications requiring durability and visual appeal. PVC (Polyvinyl Chloride) provides cost-effectiveness and flexibility, often preferred in products where budget constraints and ease of processing are critical. Choosing the right material depends on factors like environmental exposure, mechanical demands, and desired aesthetic qualities to ensure optimal performance and longevity of the final product.

BoPET vs PVC Infographic

materialdif.com

materialdif.com