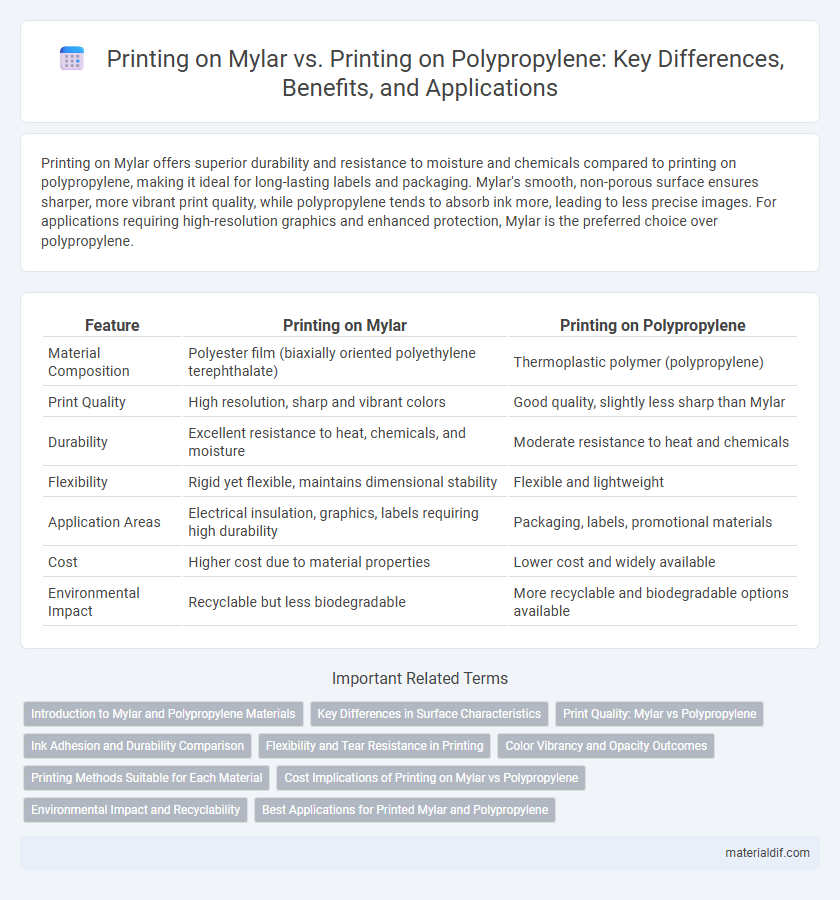

Printing on Mylar offers superior durability and resistance to moisture and chemicals compared to printing on polypropylene, making it ideal for long-lasting labels and packaging. Mylar's smooth, non-porous surface ensures sharper, more vibrant print quality, while polypropylene tends to absorb ink more, leading to less precise images. For applications requiring high-resolution graphics and enhanced protection, Mylar is the preferred choice over polypropylene.

Table of Comparison

| Feature | Printing on Mylar | Printing on Polypropylene |

|---|---|---|

| Material Composition | Polyester film (biaxially oriented polyethylene terephthalate) | Thermoplastic polymer (polypropylene) |

| Print Quality | High resolution, sharp and vibrant colors | Good quality, slightly less sharp than Mylar |

| Durability | Excellent resistance to heat, chemicals, and moisture | Moderate resistance to heat and chemicals |

| Flexibility | Rigid yet flexible, maintains dimensional stability | Flexible and lightweight |

| Application Areas | Electrical insulation, graphics, labels requiring high durability | Packaging, labels, promotional materials |

| Cost | Higher cost due to material properties | Lower cost and widely available |

| Environmental Impact | Recyclable but less biodegradable | More recyclable and biodegradable options available |

Introduction to Mylar and Polypropylene Materials

Mylar, a brand name for biaxially-oriented polyethylene terephthalate (BoPET), offers excellent dimensional stability and high tensile strength, making it ideal for high-quality printing applications requiring durability and clarity. Polypropylene, a thermoplastic polymer, is valued for its chemical resistance, flexibility, and cost-effectiveness in various printing and packaging uses. Comparing both, Mylar provides superior print surface smoothness and longevity, while polypropylene balances affordability with adequate print performance for less demanding applications.

Key Differences in Surface Characteristics

Printing on Mylar features a smooth, glossy surface that enhances ink adhesion and sharp image reproduction, resulting in vibrant, high-resolution prints. In contrast, polypropylene typically has a matte or slightly textured finish, which may absorb ink differently, leading to less crisp details and a more muted color appearance. These surface characteristics affect drying times and durability, with Mylar often providing superior resistance to smudging and moisture compared to polypropylene.

Print Quality: Mylar vs Polypropylene

Mylar offers superior print quality compared to polypropylene due to its smoother surface and higher dimensional stability, which results in sharper and more vibrant images. The clarity and glossiness of Mylar enhance color contrast, making it ideal for high-resolution graphics and detailed prints. Polypropylene, while cost-effective and durable, often produces prints with less crispness and slight color dullness due to its more porous texture.

Ink Adhesion and Durability Comparison

Printing on Mylar offers superior ink adhesion due to its smooth, non-porous polyester surface, which enhances print clarity and color vibrancy compared to polypropylene. Mylar's chemical stability ensures long-lasting durability, resisting water, UV exposure, and abrasion better than polypropylene films. Polypropylene may absorb inks unevenly, leading to faster degradation and less precise prints, making Mylar the preferred choice for high-quality, durable printing applications.

Flexibility and Tear Resistance in Printing

Printing on Mylar offers superior flexibility and exceptional tear resistance compared to polypropylene, making it ideal for applications requiring durable and pliable materials. Mylar's polyester composition provides a smooth surface that maintains print clarity under stress, while its tear-resistant properties prevent damage during handling. Polypropylene, although cost-effective, tends to be less flexible and more prone to tearing, limiting its use in high-stress printing environments.

Color Vibrancy and Opacity Outcomes

Printing on Mylar delivers superior color vibrancy due to its smooth, non-porous surface that allows ink to sit atop without absorption, resulting in sharper and more vivid images. In contrast, polypropylene's semi-porous texture absorbs some ink, leading to slightly muted colors and less intense opacity. Mylar's higher opacity levels also enhance print clarity, making it ideal for applications requiring bright, eye-catching visuals.

Printing Methods Suitable for Each Material

Printing on Mylar typically involves screen printing, flexography, and UV printing, as these methods provide excellent ink adhesion and durability on the smooth, non-porous surface. Polypropylene printing is often executed using flexography, rotogravure, and digital printing techniques, optimized for its slightly textured surface and flexibility. Choosing the appropriate printing method enhances image clarity and durability for each specific material's properties.

Cost Implications of Printing on Mylar vs Polypropylene

Printing on Mylar typically incurs higher costs compared to polypropylene due to its superior durability, clarity, and resistance to moisture and chemicals, which necessitate more specialized inks and equipment. Polypropylene printing offers a more economical solution with faster production speeds and lower material expenses, making it suitable for high-volume applications where cost efficiency is critical. Businesses must weigh the initial investment and long-term benefits of Mylar against the budget-friendly nature and versatility of polypropylene to determine the optimal choice.

Environmental Impact and Recyclability

Printing on Mylar offers a more environmentally friendly option compared to polypropylene due to its higher durability and recyclability, reducing waste accumulation. Mylar, a polyester film, is easily recyclable and breaks down less into microplastics, whereas polypropylene often results in more challenging recycling processes and contributes to plastic pollution. Choosing Mylar supports sustainability initiatives by enabling longer-lasting prints and simpler recycling streams in industrial and commercial applications.

Best Applications for Printed Mylar and Polypropylene

Printed Mylar excels in applications requiring high durability and clarity, such as outdoor banners, signs, and emergency blankets, due to its excellent moisture and tear resistance. Polypropylene printing is ideal for packaging, labels, and promotional materials that demand flexibility and cost-effectiveness, with strong resistance to chemicals and oils. Choosing Mylar or Polypropylene depends on specific needs: Mylar suits long-term outdoor use, while Polypropylene is best for lightweight, versatile packaging solutions.

Printing on Mylar vs Printing on Polypropylene Infographic

materialdif.com

materialdif.com