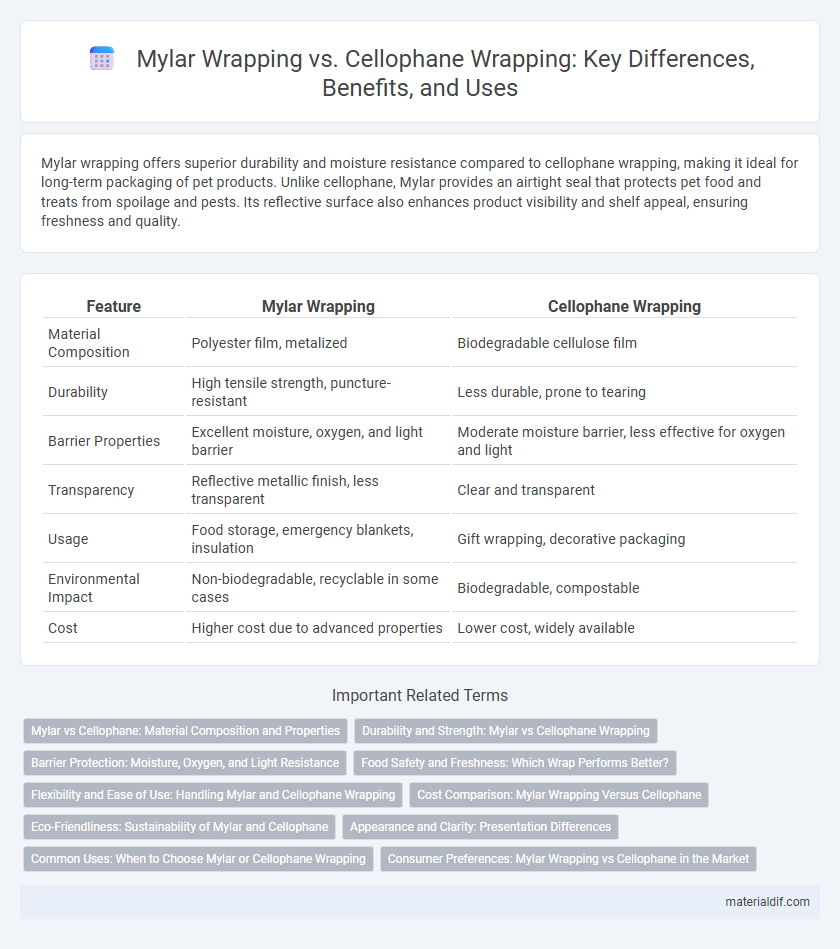

Mylar wrapping offers superior durability and moisture resistance compared to cellophane wrapping, making it ideal for long-term packaging of pet products. Unlike cellophane, Mylar provides an airtight seal that protects pet food and treats from spoilage and pests. Its reflective surface also enhances product visibility and shelf appeal, ensuring freshness and quality.

Table of Comparison

| Feature | Mylar Wrapping | Cellophane Wrapping |

|---|---|---|

| Material Composition | Polyester film, metalized | Biodegradable cellulose film |

| Durability | High tensile strength, puncture-resistant | Less durable, prone to tearing |

| Barrier Properties | Excellent moisture, oxygen, and light barrier | Moderate moisture barrier, less effective for oxygen and light |

| Transparency | Reflective metallic finish, less transparent | Clear and transparent |

| Usage | Food storage, emergency blankets, insulation | Gift wrapping, decorative packaging |

| Environmental Impact | Non-biodegradable, recyclable in some cases | Biodegradable, compostable |

| Cost | Higher cost due to advanced properties | Lower cost, widely available |

Mylar vs Cellophane: Material Composition and Properties

Mylar wrapping is made from biaxially-oriented polyethylene terephthalate (BoPET), which provides superior tensile strength, moisture resistance, and thermal stability compared to cellophane, a thin, transparent film derived from cellulose. Mylar's synthetic polymer composition allows for enhanced durability and barrier properties against oxygen and light, making it ideal for long-term food preservation and insulation applications. In contrast, cellophane is biodegradable but less resistant to moisture and heat, limiting its effectiveness in high-performance wrapping uses.

Durability and Strength: Mylar vs Cellophane Wrapping

Mylar wrapping offers superior durability and strength compared to cellophane wrapping, due to its polyester film composition which provides excellent tear resistance and puncture protection. Cellophane, made from cellulose, is more prone to tearing and less effective at preserving contents under stress. The high tensile strength of Mylar ensures long-lasting protection in various packaging and storage applications.

Barrier Protection: Moisture, Oxygen, and Light Resistance

Mylar wrapping offers superior barrier protection against moisture, oxygen, and light compared to cellophane wrapping, thanks to its multilayer polyester film structure. This enhanced resistance significantly extends the shelf life of products by preventing degradation and preserving freshness. Cellophane, being more permeable, provides limited protection against these elements, making Mylar the preferred choice for sensitive goods requiring long-term preservation.

Food Safety and Freshness: Which Wrap Performs Better?

Mylar wrapping offers superior food safety and freshness compared to cellophane due to its multi-layered polyester composition that provides an excellent barrier against moisture, oxygen, and light. This barrier significantly prolongs shelf life and maintains the flavor and texture of food products by preventing contamination and spoilage. Cellophane, being biodegradable but more permeable, allows gas exchange that can accelerate food deterioration, making Mylar the preferred choice for long-term food preservation.

Flexibility and Ease of Use: Handling Mylar and Cellophane Wrapping

Mylar wrapping offers superior flexibility and durability compared to cellophane, allowing it to conform tightly to irregular shapes without tearing. The thicker, more resilient material of Mylar provides enhanced ease of use during handling, reducing the risk of punctures or wrinkles. Cellophane, while more transparent and eco-friendly, tends to be stiffer and more prone to tearing, making it less adaptable for intricate wrapping tasks.

Cost Comparison: Mylar Wrapping Versus Cellophane

Mylar wrapping generally costs more than cellophane due to its superior durability, moisture resistance, and barrier properties, which extend product shelf life. Cellophane is more affordable but offers lower protection against oxygen and humidity, making it less suitable for long-term packaging. Businesses must weigh upfront wrapping expenses against product preservation benefits when choosing between Mylar and cellophane.

Eco-Friendliness: Sustainability of Mylar and Cellophane

Mylar wrapping, made from biaxially-oriented polyethylene terephthalate (BoPET), is durable and recyclable, but its production relies heavily on petroleum-based plastics, raising concerns about long-term sustainability. Cellophane, derived from cellulose, is biodegradable and compostable, offering a more eco-friendly alternative, although it has lower moisture resistance compared to Mylar. Choosing Between Mylar and Cellophane wrapping requires balancing the recyclable nature of Mylar with the inherently biodegradable properties of cellophane in sustainable packaging decisions.

Appearance and Clarity: Presentation Differences

Mylar wrapping offers a sleek, glossy finish that enhances product appearance with high clarity and durability, making it ideal for premium packaging. Cellophane wrapping provides a more natural, matte look with moderate transparency, allowing products to be visible but with less vibrancy than Mylar. The choice between Mylar and cellophane impacts product visibility and shelf appeal, with Mylar excelling in crisp, clear presentation and longevity.

Common Uses: When to Choose Mylar or Cellophane Wrapping

Mylar wrapping is preferred for food storage and preservation due to its excellent barrier properties against moisture, oxygen, and light, extending shelf life for items like dried foods and pharmaceuticals. Cellophane wrapping is commonly used for gift packaging, floral wrapping, and bakery items where breathability and aesthetic appeal are important. Choose Mylar for airtight protection and durability, while cellophane is ideal for decorative presentation and moderate moisture resistance.

Consumer Preferences: Mylar Wrapping vs Cellophane in the Market

Consumer preferences in packaging reveal a strong inclination toward Mylar wrapping due to its superior durability, moisture resistance, and oxygen barrier properties compared to cellophane. Mylar's high tensile strength and airtight seal extend product freshness, making it ideal for food, electronics, and pharmaceuticals, whereas cellophane is favored for its biodegradability and aesthetic appeal in gift wrapping and retail packaging. Market trends indicate that consumers prioritize preservation and long shelf life when selecting Mylar, while environmental consciousness drives demand for cellophane despite its lower protective capabilities.

Mylar Wrapping vs Cellophane Wrapping Infographic

materialdif.com

materialdif.com