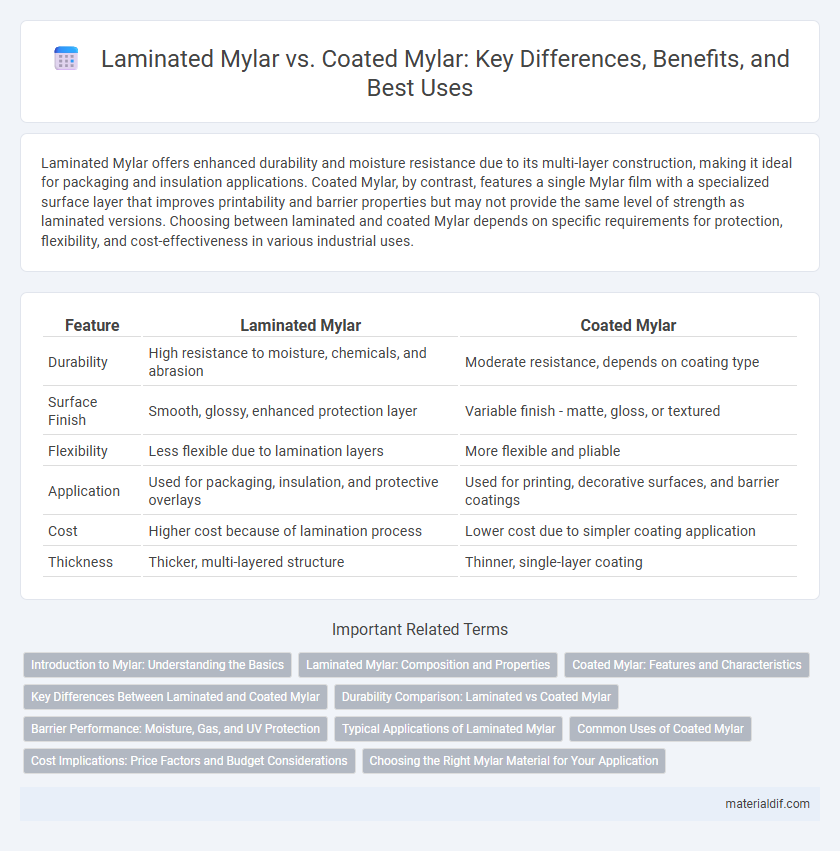

Laminated Mylar offers enhanced durability and moisture resistance due to its multi-layer construction, making it ideal for packaging and insulation applications. Coated Mylar, by contrast, features a single Mylar film with a specialized surface layer that improves printability and barrier properties but may not provide the same level of strength as laminated versions. Choosing between laminated and coated Mylar depends on specific requirements for protection, flexibility, and cost-effectiveness in various industrial uses.

Table of Comparison

| Feature | Laminated Mylar | Coated Mylar |

|---|---|---|

| Durability | High resistance to moisture, chemicals, and abrasion | Moderate resistance, depends on coating type |

| Surface Finish | Smooth, glossy, enhanced protection layer | Variable finish - matte, gloss, or textured |

| Flexibility | Less flexible due to lamination layers | More flexible and pliable |

| Application | Used for packaging, insulation, and protective overlays | Used for printing, decorative surfaces, and barrier coatings |

| Cost | Higher cost because of lamination process | Lower cost due to simpler coating application |

| Thickness | Thicker, multi-layered structure | Thinner, single-layer coating |

Introduction to Mylar: Understanding the Basics

Mylar is a polyester film known for its durability, clarity, and electrical insulation properties, commonly used in various industrial and consumer applications. Laminated Mylar consists of multiple layers bonded together, enhancing strength, moisture resistance, and dimensional stability, making it ideal for packaging and protective coverings. Coated Mylar features a surface treatment or coating to improve heat resistance, chemical resistance, or adhesive properties, frequently utilized in printing, labeling, and specialized insulation.

Laminated Mylar: Composition and Properties

Laminated Mylar consists of multiple layers of polyester film bonded together to enhance durability, flexibility, and resistance to moisture and chemicals. Its composite structure provides superior tensile strength and dimensional stability compared to single-layer coated Mylar. This makes laminated Mylar ideal for applications requiring high-performance insulation, protective barriers, and long-lasting packaging solutions.

Coated Mylar: Features and Characteristics

Coated Mylar features a durable polymer layer applied to its surface, enhancing its resistance to moisture, chemicals, and abrasion, making it ideal for protective packaging and industrial applications. This coating improves the film's printability and electrical insulation properties, offering versatility in labels, insulation, and flexible electronics. Its ability to maintain clarity and strength under harsh conditions distinguishes Coated Mylar from laminated variants, which primarily focus on multi-layer bonding for added thickness and rigidity.

Key Differences Between Laminated and Coated Mylar

Laminated Mylar is a multi-layer film where a protective plastic layer is bonded to a Mylar base, enhancing durability, moisture resistance, and tear strength, making it ideal for long-term packaging and insulation. Coated Mylar, in contrast, involves applying a thin surface treatment or chemical layer to the Mylar film, improving properties such as UV protection, printability, and barrier functions without adding thickness. Key differences include the enhanced mechanical strength and longevity of laminated Mylar versus the specialized surface properties and cost-effectiveness of coated Mylar.

Durability Comparison: Laminated vs Coated Mylar

Laminated Mylar offers superior durability due to its multi-layer construction, which provides enhanced resistance to moisture, tearing, and chemical exposure compared to Coated Mylar. Coated Mylar relies on a thin protective layer that improves surface resistance but is more susceptible to wear and damage over time. In industrial and archival applications, Laminated Mylar is preferred for long-term protection and structural integrity.

Barrier Performance: Moisture, Gas, and UV Protection

Laminated Mylar offers superior barrier performance against moisture, gases, and UV radiation due to its multiple layers of protective films bonded together, enhancing durability and extending shelf life. Coated Mylar provides moisture resistance and UV protection through a single film with applied coatings but generally has lower gas barrier properties compared to laminated versions. For applications requiring extensive protection against oxygen and prolonged UV exposure, laminated Mylar is the preferred choice.

Typical Applications of Laminated Mylar

Laminated Mylar is widely used in applications requiring enhanced durability and moisture resistance, such as flexible packaging, electrical insulation, and protective coverings for electronic components. Its multi-layer structure provides superior strength and barrier properties, making it ideal for food packaging, pharmaceuticals, and insulation films. The laminate's ability to maintain clarity and resist chemicals ensures reliable performance in industrial and commercial uses.

Common Uses of Coated Mylar

Coated Mylar is commonly used in applications requiring enhanced moisture resistance and durability, such as food packaging, insulation, and electrical insulation. Its surface treatment improves adhesion for printing, making it ideal for labels and promotional materials. The coating also provides UV protection, extending the lifespan of outdoor graphics and signage.

Cost Implications: Price Factors and Budget Considerations

Laminated Mylar typically incurs higher costs due to the multi-layer bonding process, enhancing durability and moisture resistance, which justifies the premium for long-term applications. Coated Mylar, being a single substrate with a surface treatment, usually offers a more budget-friendly option but may compromise on longevity and protection. Businesses must weigh the initial price difference against potential replacement frequency and performance requirements when considering cost implications.

Choosing the Right Mylar Material for Your Application

Laminated Mylar offers superior durability and moisture resistance, making it ideal for applications requiring long-term protection and robust structural integrity. Coated Mylar, with its specialized surface treatments, provides enhanced chemical resistance and improved printability, suited for packaging and decorative uses. Selecting the right Mylar material depends on the specific environmental conditions and functional requirements of your application, balancing factors like barrier properties, flexibility, and cost.

Laminated Mylar vs Coated Mylar Infographic

materialdif.com

materialdif.com