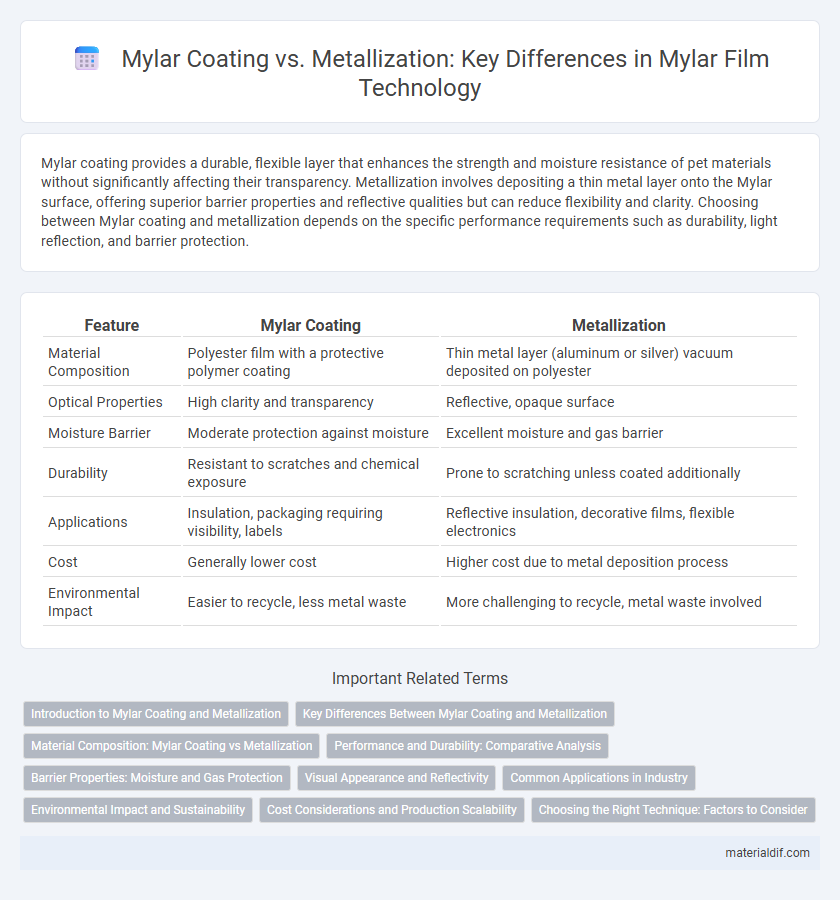

Mylar coating provides a durable, flexible layer that enhances the strength and moisture resistance of pet materials without significantly affecting their transparency. Metallization involves depositing a thin metal layer onto the Mylar surface, offering superior barrier properties and reflective qualities but can reduce flexibility and clarity. Choosing between Mylar coating and metallization depends on the specific performance requirements such as durability, light reflection, and barrier protection.

Table of Comparison

| Feature | Mylar Coating | Metallization |

|---|---|---|

| Material Composition | Polyester film with a protective polymer coating | Thin metal layer (aluminum or silver) vacuum deposited on polyester |

| Optical Properties | High clarity and transparency | Reflective, opaque surface |

| Moisture Barrier | Moderate protection against moisture | Excellent moisture and gas barrier |

| Durability | Resistant to scratches and chemical exposure | Prone to scratching unless coated additionally |

| Applications | Insulation, packaging requiring visibility, labels | Reflective insulation, decorative films, flexible electronics |

| Cost | Generally lower cost | Higher cost due to metal deposition process |

| Environmental Impact | Easier to recycle, less metal waste | More challenging to recycle, metal waste involved |

Introduction to Mylar Coating and Metallization

Mylar coating enhances the surface properties of polyethylene terephthalate (PET) film by adding a protective polymer layer, improving durability, moisture resistance, and printability. Metallization involves depositing a thin metal layer, typically aluminum, onto Mylar, creating a reflective barrier that enhances conductivity and light reflectance. Both techniques optimize Mylar film performance for packaging, insulation, and electronic applications by tailoring physical and optical characteristics.

Key Differences Between Mylar Coating and Metallization

Mylar coating involves applying a clear protective layer on the polyester film to enhance durability, chemical resistance, and electrical insulation, while metallization deposits a thin metal layer, typically aluminum, to improve reflectivity, conductivity, and barrier properties. The key differences lie in their functional purposes: coating aims to safeguard and insulate the film, whereas metallization focuses on adding metallic characteristics such as increased light reflection and electromagnetic shielding. These distinctions influence their applications, with coated Mylar used in packaging and insulation, and metallized Mylar popular in electronics and decorative films.

Material Composition: Mylar Coating vs Metallization

Mylar coating involves applying a polymer layer, typically polyethylene terephthalate (PET), enhanced with protective compounds to increase durability, flexibility, and resistance to moisture and chemicals. Metallization on Mylar consists of depositing a thin metallic layer, often aluminum, onto the PET film surface, providing superior reflectivity, electrical conductivity, and barrier properties. The key difference lies in the material composition: Mylar coating primarily modifies the polymer surface for added protection, while metallization overlays a conductive metal film to enhance optical and physical characteristics.

Performance and Durability: Comparative Analysis

Mylar coating offers superior resistance to moisture and chemicals, enhancing durability in harsh environments, while metallization provides excellent reflective properties and improved barrier performance against oxygen and light. The performance of Mylar coating excels in flexibility and abrasion resistance, making it ideal for applications requiring repeated handling or bending. Metallized Mylar films deliver enhanced thermal insulation and longer shelf life for packaged goods but may be more prone to cracking under mechanical stress compared to coated variants.

Barrier Properties: Moisture and Gas Protection

Mylar coating provides a protective polymer layer enhancing moisture resistance but offers limited gas barrier properties compared to metallization. Metallized Mylar incorporates a thin aluminum layer significantly improving gas impermeability, crucial for packaging sensitive items requiring extended shelf life. Combining Mylar coating with metallization optimizes barrier protection, balancing moisture resistance and gas barrier performance effectively.

Visual Appearance and Reflectivity

Mylar coating provides a smooth, glossy finish that enhances color vibrancy and clarity, making it ideal for decorative applications requiring high visual appeal. Metallization on Mylar introduces a reflective metallic surface with superior reflectivity, often used in insulation and packaging to maximize light and heat reflection. While coated Mylar emphasizes aesthetic quality through color enhancement, metallized Mylar prioritizes functional reflectivity with a mirror-like appearance.

Common Applications in Industry

Mylar coating is widely used in electrical insulation, packaging, and protective films due to its excellent chemical resistance and flexibility. Metallization of Mylar enhances barrier properties and reflectivity, making it ideal for applications in electronics, solar panels, and decorative packaging. Industries such as aerospace, automotive, and food packaging rely heavily on the tailored benefits of both Mylar coatings and metallized films to meet specific performance standards.

Environmental Impact and Sustainability

Mylar coating offers a more environmentally friendly alternative to metallization by reducing the use of metal-based materials and lowering energy consumption during production. Metallization involves vacuum-deposited metal layers, which generate hazardous waste and increase carbon emissions. Biodegradability and recyclability are higher in coated Mylar films, promoting sustainability in packaging and insulation industries.

Cost Considerations and Production Scalability

Mylar coating typically incurs lower initial costs due to simpler application processes and reduced material expenses compared to metallization, which involves vacuum deposition techniques that are more costly and time-intensive. Production scalability favors Mylar coating as it allows faster throughput and easier adaptation to varying batch sizes, whereas metallization often requires specialized equipment limiting rapid scale-up. Operational budgets and project timelines often drive the choice between cost-effective, scalable Mylar coatings and the premium, precision metallized finishes.

Choosing the Right Technique: Factors to Consider

Choosing between Mylar coating and metallization depends on factors such as desired barrier properties, durability, and cost-effectiveness in packaging applications. Mylar coating offers excellent chemical resistance and flexibility, making it ideal for food packaging, while metallization provides superior moisture and oxygen barriers with a reflective finish, enhancing product shelf life. Assessing environmental impact, production complexity, and specific performance requirements ensures the selection of the optimal technique for efficient and sustainable packaging solutions.

Mylar Coating vs Metallization Infographic

materialdif.com

materialdif.com