Mylar printing offers superior durability and resistance to tearing compared to polyethylene printing, making it ideal for long-lasting pet products. Mylar films provide excellent barrier properties against moisture and gases, enhancing the preservation of pet food freshness. In contrast, polyethylene printing is more cost-effective but less sturdy and less effective in maintaining product integrity over time.

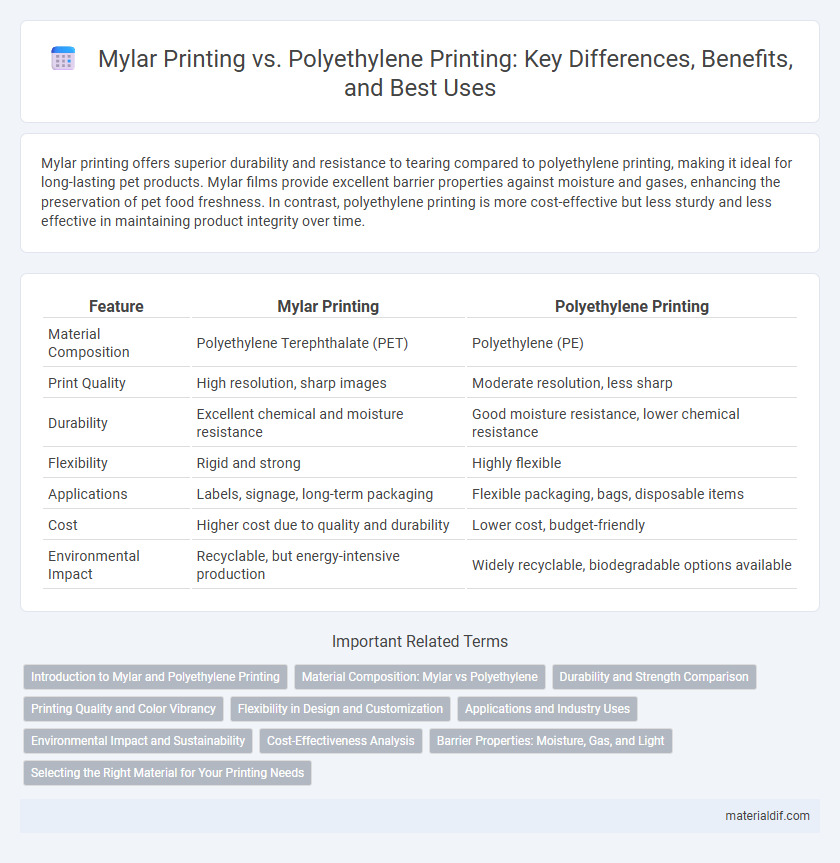

Table of Comparison

| Feature | Mylar Printing | Polyethylene Printing |

|---|---|---|

| Material Composition | Polyethylene Terephthalate (PET) | Polyethylene (PE) |

| Print Quality | High resolution, sharp images | Moderate resolution, less sharp |

| Durability | Excellent chemical and moisture resistance | Good moisture resistance, lower chemical resistance |

| Flexibility | Rigid and strong | Highly flexible |

| Applications | Labels, signage, long-term packaging | Flexible packaging, bags, disposable items |

| Cost | Higher cost due to quality and durability | Lower cost, budget-friendly |

| Environmental Impact | Recyclable, but energy-intensive production | Widely recyclable, biodegradable options available |

Introduction to Mylar and Polyethylene Printing

Mylar printing offers superior durability and clarity due to its polyester film base, making it ideal for high-quality graphics and labels that require resistance to moisture and chemicals. In contrast, polyethylene printing uses a flexible, lightweight plastic often favored for packaging applications where cost efficiency and versatility are prioritized. Both materials serve distinct purposes in printing technology, with Mylar excelling in long-lasting, high-definition prints and polyethylene providing economical, flexible solutions for everyday use.

Material Composition: Mylar vs Polyethylene

Mylar printing utilizes biaxially-oriented polyethylene terephthalate (BoPET), a polyester film known for its high tensile strength, chemical stability, and excellent clarity, which enhances print durability and color vibrancy. Polyethylene printing employs a polymer composed of long chains of ethylene molecules, offering flexibility and impact resistance but lower temperature tolerance and dimensional stability compared to Mylar. The superior material composition of Mylar makes it ideal for applications requiring strength, transparency, and resistance to moisture and gases, whereas polyethylene suits flexible packaging with less demanding environmental conditions.

Durability and Strength Comparison

Mylar printing offers superior durability and tensile strength compared to polyethylene printing, making it ideal for long-term use in harsh environments. Mylar's polyester base resists tearing, moisture, and UV exposure more effectively than polyethylene films, which tend to degrade faster under similar conditions. The enhanced dimensional stability of Mylar ensures that printed materials maintain clarity and adhesion over extended periods, outperforming polyethylene in demanding applications.

Printing Quality and Color Vibrancy

Mylar printing offers superior printing quality and color vibrancy compared to polyethylene printing due to its smooth, non-porous surface that allows for sharper image resolution and more vivid color reproduction. The durable polyester composition of Mylar withstands ink absorption better, resulting in longer-lasting prints with intensified hues and crisp details. In contrast, polyethylene's porous texture often leads to duller colors and less precise printing outcomes, making Mylar the preferred choice for applications requiring high visual impact.

Flexibility in Design and Customization

Mylar printing offers superior flexibility in design and customization compared to polyethylene printing, enabling high-resolution graphics and vibrant color reproduction on smooth, reflective surfaces. The durable polyester film of Mylar allows intricate detailing and sharp text, making it ideal for premium packaging and promotional materials. Polyethylene printing, while cost-effective, often results in less precise imagery and limited color vibrancy due to its lower surface quality and print receptivity.

Applications and Industry Uses

Mylar printing excels in applications requiring high durability, chemical resistance, and excellent clarity, making it ideal for industrial labeling, outdoor signage, and electronics insulation. Polyethylene printing, favored for flexibility and moisture resistance, is commonly used in food packaging, agricultural films, and medical disposables. Industries such as aerospace and automotive prefer Mylar for its thermal stability, while polyethylene dominates consumer goods packaging due to cost-effectiveness and versatility.

Environmental Impact and Sustainability

Mylar printing offers superior durability and recyclability compared to polyethylene printing, contributing to reduced environmental waste and enhanced sustainability. Mylar's polyester composition enables efficient recycling processes, lowering carbon footprint and minimizing landfill impact. In contrast, polyethylene, derived from fossil fuels, tends to have a shorter lifecycle and limited recyclability, posing challenges for eco-friendly disposal and long-term sustainability.

Cost-Effectiveness Analysis

Mylar printing offers superior durability and print quality compared to polyethylene printing, often justifying its higher initial cost through extended product lifespan and enhanced visual appeal. Polyethylene printing boasts lower upfront expenses making it suitable for short-term applications or budget-conscious projects. Cost-effectiveness analysis reveals that while polyethylene may reduce immediate costs, Mylar's resilience and resistance to environmental factors provide better long-term economic value.

Barrier Properties: Moisture, Gas, and Light

Mylar printing offers superior barrier properties compared to polyethylene printing, effectively blocking moisture, oxygen, and light to extend product shelf life. Its polyester film composition provides a dense molecular structure that significantly reduces permeability, ensuring better protection for sensitive goods. Polyethylene, while cost-effective and flexible, allows higher moisture and gas transmission rates, making Mylar the preferred choice for high-barrier packaging applications.

Selecting the Right Material for Your Printing Needs

Mylar printing offers superior durability, clarity, and resistance to moisture and chemicals compared to polyethylene printing, making it ideal for high-quality, long-lasting labels and graphics. Polyethylene printing, while more cost-effective and flexible, suits applications requiring lightweight and tear-resistant materials, such as packaging films and disposable items. Selecting the right material depends on balancing factors like environmental exposure, print quality demands, and budget constraints to ensure optimal performance and longevity.

Mylar Printing vs Polyethylene Printing Infographic

materialdif.com

materialdif.com