BoPET (Biaxially Oriented Polyethylene Terephthalate) is a specific type of Mylar known for its superior tensile strength and chemical stability compared to generic Mylar films. Mylar typically refers to polyester films used in various applications, but BoPET offers enhanced durability, dimensional stability, and resistance to moisture and gases, making it the preferred choice for high-performance packaging and insulation. While both share the same polyester base, BoPET's biaxial orientation process provides enhanced optical clarity and mechanical properties, distinguishing it from standard Mylar.

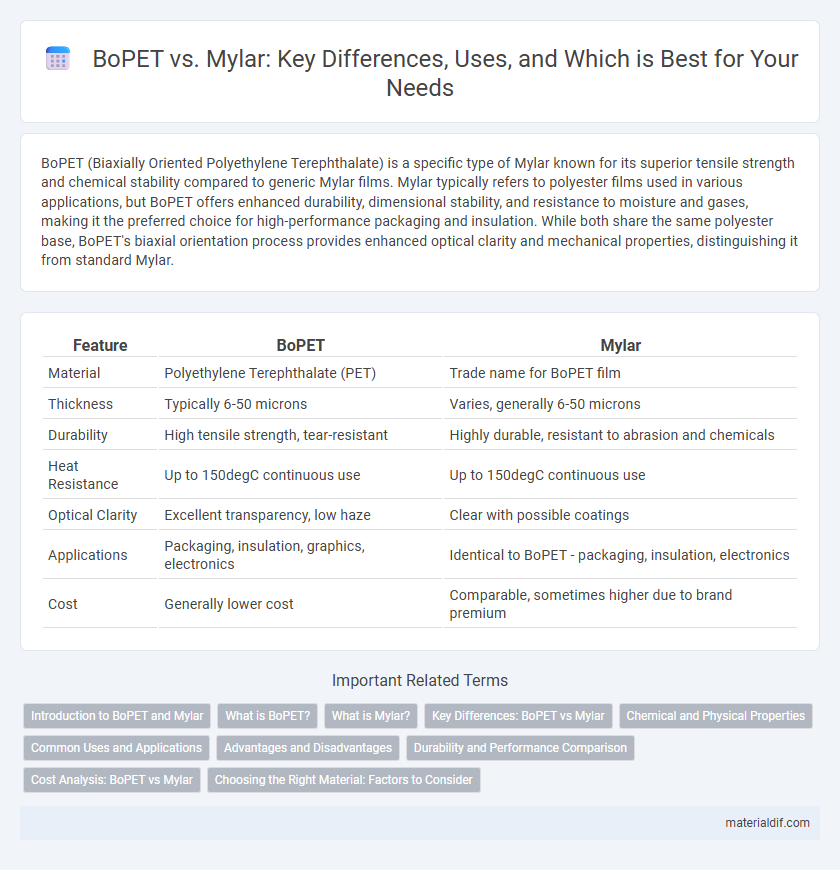

Table of Comparison

| Feature | BoPET | Mylar |

|---|---|---|

| Material | Polyethylene Terephthalate (PET) | Trade name for BoPET film |

| Thickness | Typically 6-50 microns | Varies, generally 6-50 microns |

| Durability | High tensile strength, tear-resistant | Highly durable, resistant to abrasion and chemicals |

| Heat Resistance | Up to 150degC continuous use | Up to 150degC continuous use |

| Optical Clarity | Excellent transparency, low haze | Clear with possible coatings |

| Applications | Packaging, insulation, graphics, electronics | Identical to BoPET - packaging, insulation, electronics |

| Cost | Generally lower cost | Comparable, sometimes higher due to brand premium |

Introduction to BoPET and Mylar

BoPET (Biaxially Oriented Polyethylene Terephthalate) and Mylar are both types of polyester films known for their durability, flexibility, and chemical resistance. BoPET is a generic term for the biaxially oriented form of PET film used in various industries for packaging, insulation, and electronics, while Mylar is DuPont's trademarked version of BoPET renowned for exceptional tensile strength and thermal stability. Both materials offer excellent barrier properties and high dimensional stability, making them ideal for applications requiring moisture and gas resistance.

What is BoPET?

BoPET, or Biaxially Oriented Polyethylene Terephthalate, is a polyester film known for its high tensile strength, chemical stability, and excellent electrical insulation properties. Unlike standard Mylar, which is a brand name for PET films, BoPET undergoes a biaxial orientation process that enhances its mechanical and barrier qualities. This makes BoPET ideal for applications in packaging, electronics, and insulation where durability and resistance to moisture and gases are critical.

What is Mylar?

Mylar is a brand name for a type of BoPET (Biaxially-oriented polyethylene terephthalate) film known for its exceptional tensile strength, chemical stability, and electrical insulation properties. Unlike generic BoPET films, Mylar is specially coated for enhanced durability and heat resistance, making it ideal for applications like packaging, insulation, and flexible electronics. Its unique manufacturing process aligns polymer chains in two directions, resulting in superior dimensional stability and clarity compared to standard polyester films.

Key Differences: BoPET vs Mylar

BoPET (Biaxially Oriented Polyethylene Terephthalate) is a specific type of polyester film known for its exceptional strength, clarity, and barrier properties, whereas Mylar is a brand name commonly used to refer to polyester films, including BoPET. Key differences include BoPET's enhanced dimensional stability and higher tensile strength compared to generic Mylar films, making it more suitable for advanced applications like flexible electronics and high-performance insulation. Mylar encompasses a range of polyester films with varying thickness and treatments, but BoPET stands out due to its biaxial orientation process that improves mechanical and thermal properties.

Chemical and Physical Properties

BoPET (Biaxially-Oriented Polyethylene Terephthalate) and Mylar share similar chemical compositions as both are polyester films made from polyethylene terephthalate, but BoPET undergoes biaxial stretching that enhances its tensile strength and dimensional stability. Mylar typically refers to a trade name that encompasses various PET films, including BoPET, and is known for its flexibility, excellent barrier properties, and resistance to moisture, gases, and chemicals. The biaxial orientation process in BoPET improves physical properties like clarity, strength, and temperature resistance, making it preferred in applications requiring durability and stability compared to standard Mylar films.

Common Uses and Applications

BoPET (Biaxially Oriented Polyethylene Terephthalate) and Mylar are frequently used in packaging, insulation, and electronics due to their excellent tensile strength and thermal stability. BoPET is commonly utilized in flexible printed circuits, solar panels, and food packaging films because of its clarity and barrier properties, whereas Mylar is often applied in insulation materials, emergency blankets, and decorative balloons for its reflective surface and durability. Both materials serve in applications requiring chemical resistance and dimensional stability but differ slightly in industry-specific usage based on processing and finishing techniques.

Advantages and Disadvantages

BoPET (Biaxially Oriented Polyethylene Terephthalate) and Mylar both offer high tensile strength and excellent chemical resistance, but BoPET typically provides superior dimensional stability and clarity, making it ideal for applications requiring precise optical properties. Mylar, a brand name for BoPET, often includes variations with unique coatings or thicknesses, which can enhance barrier properties or flexibility, but may increase cost. Disadvantages of BoPET include susceptibility to UV degradation without protective coatings, whereas Mylar's proprietary treatments can offer improved durability but might limit recyclability.

Durability and Performance Comparison

BoPET (Biaxially-oriented polyethylene terephthalate) and Mylar both offer exceptional durability, but BoPET exhibits higher tensile strength and enhanced resistance to stretching, making it superior for long-term performance. Mylar, a trademarked form of BoPET, provides excellent dimensional stability and resistance to moisture, heat, and chemicals, contributing to its widespread use in insulation and packaging. While both materials perform well in demanding environments, BoPET's enhanced mechanical properties often result in better durability under extreme conditions.

Cost Analysis: BoPET vs Mylar

BoPET typically offers a more cost-effective solution compared to Mylar due to its widespread production and availability, leading to lower raw material prices. While both materials share similar properties such as high tensile strength and thermal stability, BoPET's manufacturing process benefits from economies of scale, reducing overall costs. However, Mylar remains preferred for specialized applications demanding enhanced chemical resistance and durability despite a higher price point.

Choosing the Right Material: Factors to Consider

BoPET offers superior tensile strength and chemical stability, making it ideal for industrial applications requiring durability and heat resistance. Mylar, a brand name for PET film, provides versatility in thickness and transparency options, suitable for packaging and insulation uses. When choosing between BoPET and Mylar, consider factors such as thermal stability, moisture resistance, and optical clarity based on the specific requirements of your project.

BoPET vs Mylar Infographic

materialdif.com

materialdif.com