Mylar barrier films offer superior moisture and oxygen resistance compared to cellophane barriers, providing enhanced protection for pet food freshness and nutritional value. Unlike cellophane, Mylar's durability resists punctures and environmental stress, ensuring longer shelf life and maintaining flavor integrity. These properties make Mylar an ideal choice for high-quality pet packaging applications requiring reliable barrier performance.

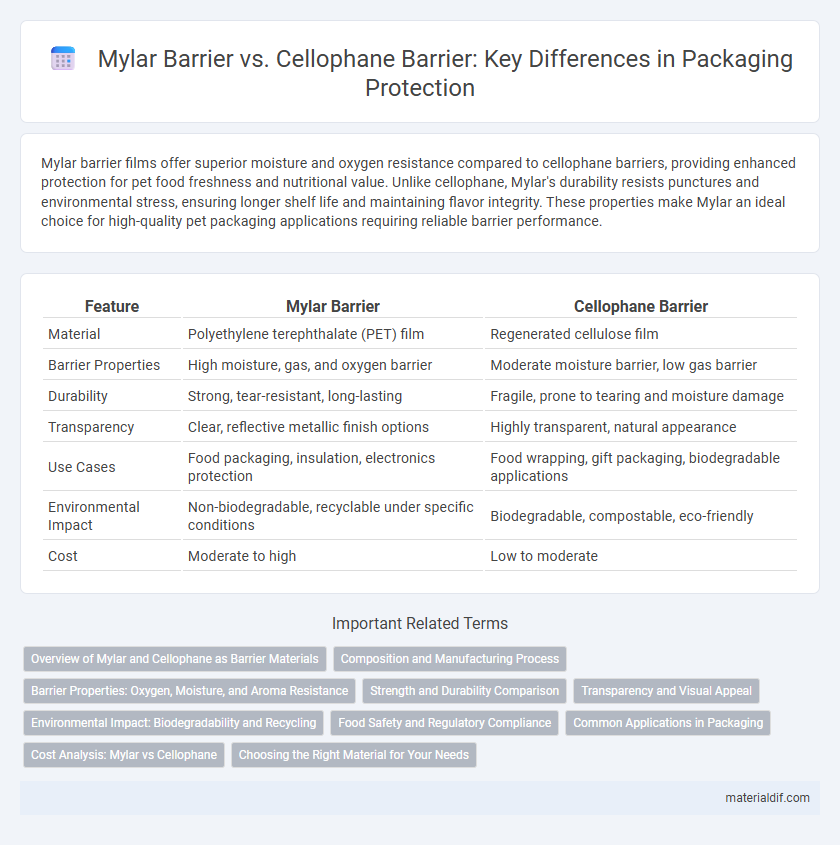

Table of Comparison

| Feature | Mylar Barrier | Cellophane Barrier |

|---|---|---|

| Material | Polyethylene terephthalate (PET) film | Regenerated cellulose film |

| Barrier Properties | High moisture, gas, and oxygen barrier | Moderate moisture barrier, low gas barrier |

| Durability | Strong, tear-resistant, long-lasting | Fragile, prone to tearing and moisture damage |

| Transparency | Clear, reflective metallic finish options | Highly transparent, natural appearance |

| Use Cases | Food packaging, insulation, electronics protection | Food wrapping, gift packaging, biodegradable applications |

| Environmental Impact | Non-biodegradable, recyclable under specific conditions | Biodegradable, compostable, eco-friendly |

| Cost | Moderate to high | Low to moderate |

Overview of Mylar and Cellophane as Barrier Materials

Mylar, a polyester film known for its exceptional tensile strength and chemical stability, offers superior barrier properties against moisture, oxygen, and gases compared to cellophane, which is a regenerated cellulose film with moderate barrier effectiveness primarily against gases. Mylar's molecular structure provides enhanced impermeability, making it ideal for sensitive applications in food packaging and electronics, whereas cellophane's natural biodegradability limits its barrier performance and industrial usage. The superior barrier characteristics of Mylar extend product shelf life and maintain integrity under varying environmental conditions.

Composition and Manufacturing Process

Mylar is a polyester film composed primarily of polyethylene terephthalate (PET), produced through a sophisticated biaxial orientation process that enhances its strength and barrier properties. In contrast, cellophane is made from regenerated cellulose derived from wood pulp, typically manufactured via a viscose process involving cellulose dissolution and reformation. The synthetic nature of Mylar's composition and its precise extrusion and stretching techniques result in superior moisture and gas barrier performance compared to the more natural cellulose-based, less uniform cellophane barrier.

Barrier Properties: Oxygen, Moisture, and Aroma Resistance

Mylar offers superior oxygen barrier properties with oxygen transmission rates typically below 0.02 cc/m2/day, significantly outperforming cellophane, which has rates ranging from 2 to 10 cc/m2/day. Moisture resistance in Mylar is enhanced by its polyethylene coating, reducing water vapor transmission to approximately 0.03 g/m2/day, whereas cellophane's moisture barrier is weaker, often exceeding 1.0 g/m2/day. Aroma retention is more effective in Mylar due to its dense polyester structure, preventing flavor loss and external odor absorption better than cellophane, which is more permeable to volatile compounds.

Strength and Durability Comparison

Mylar barrier films offer superior strength and durability compared to cellophane barriers due to their polyester base, which provides higher tensile strength and resistance to tearing. Mylar's enhanced moisture and oxygen barrier properties ensure prolonged protection in packaging applications, outperforming cellophane's more fragile cellulose structure. This increased durability makes Mylar ideal for long-term storage and industrial uses where consistent barrier performance is critical.

Transparency and Visual Appeal

Mylar Barrier offers superior transparency compared to Cellophane Barrier, providing clearer, more vibrant product visibility essential for high-end packaging. The glossy, reflective surface of Mylar enhances visual appeal, creating a premium look that attracts consumers. Cellophane, while natural and biodegradable, tends to have a slightly hazy finish, which can diminish the clarity and brightness of packaged goods.

Environmental Impact: Biodegradability and Recycling

Mylar barrier films offer superior recyclability compared to cellophane, as Mylar is made from polyethylene terephthalate (PET), a widely recyclable plastic, while cellophane, derived from cellulose, is biodegradable but less compatible with most recycling systems. The biodegradability of cellophane enables it to break down naturally, reducing long-term environmental impact, unlike Mylar which persists in the environment if not properly recycled. Choosing between Mylar and cellophane involves balancing the recyclability of synthetic polymers with the natural decomposition of cellulose-based materials.

Food Safety and Regulatory Compliance

Mylar barriers provide superior food safety by offering excellent moisture, oxygen, and light resistance, which significantly extends product shelf life compared to cellophane. Mylar films comply with FDA and EU food contact regulations, ensuring safe use in packaging sensitive food items. Cellophane barriers, while biodegradable, lack the same robust protective properties and consistent regulatory certifications, making Mylar the preferred choice for regulatory-compliant, high-performance food packaging.

Common Applications in Packaging

Mylar barrier films provide superior moisture, oxygen, and chemical resistance, making them ideal for packaging sensitive electronics, pharmaceuticals, and food products requiring extended shelf life. Cellophane barriers offer natural biodegradability and breathability, commonly used in packaging fresh produce, bakery items, and candies where environmental sustainability is prioritized. Both materials are selected based on specific barrier properties and application requirements in the packaging industry.

Cost Analysis: Mylar vs Cellophane

Mylar offers a superior moisture and oxygen barrier compared to cellophane, often justifying its higher initial cost with enhanced product preservation and longer shelf life. Cellophane, while more affordable upfront, provides less protection against environmental factors, potentially increasing long-term expenses due to product spoilage. Businesses prioritizing durability and extended freshness typically find Mylar to be a more cost-effective option despite its premium price.

Choosing the Right Material for Your Needs

Mylar Barrier films provide superior moisture and gas resistance compared to Cellophane Barrier, making them ideal for packaging sensitive products like electronics and food. Cellophane offers natural biodegradability and a moderate barrier effect, suitable for eco-friendly applications with lower preservation needs. Selecting the right material depends on prioritizing either high barrier properties for product protection or environmental sustainability for disposable packaging.

Mylar Barrier vs Cellophane Barrier Infographic

materialdif.com

materialdif.com