Mylar capacitors offer superior stability and low dielectric absorption, making them ideal for audio and precision timing applications compared to ceramic capacitors, which can exhibit microphonic effects and voltage-dependent capacitance. Their polyester film construction allows for higher insulation resistance and better frequency response, while ceramic capacitors typically provide higher capacitance in smaller packages but with less linearity. Choosing between Mylar and ceramic capacitors depends on the specific circuit requirements, emphasizing reliability, noise performance, and size constraints.

Table of Comparison

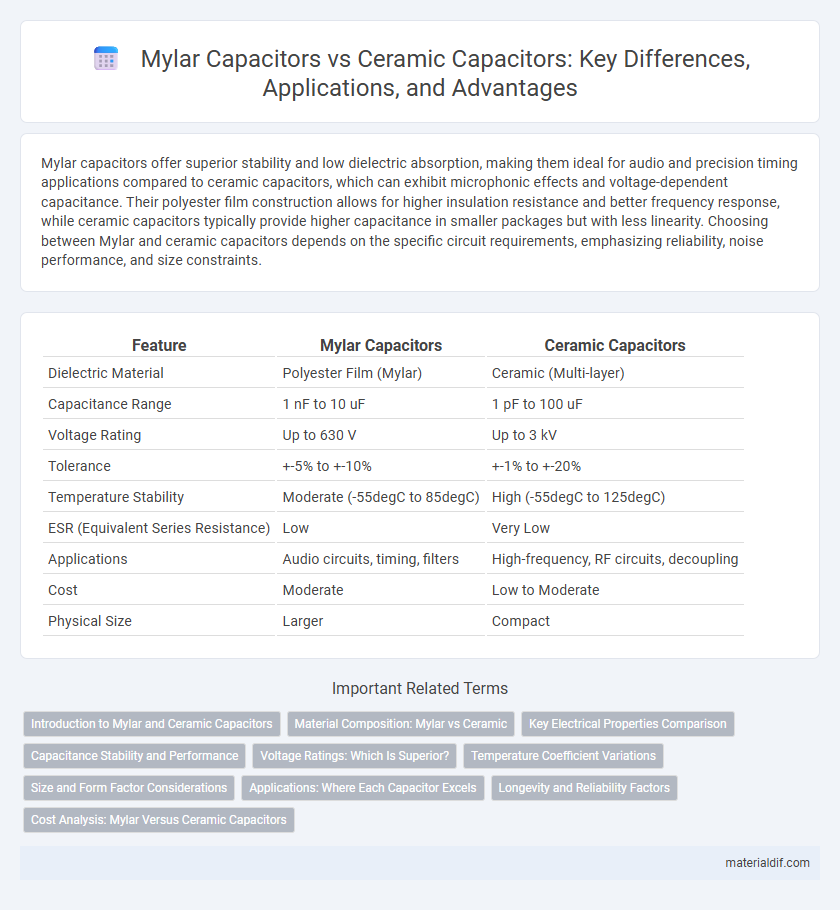

| Feature | Mylar Capacitors | Ceramic Capacitors |

|---|---|---|

| Dielectric Material | Polyester Film (Mylar) | Ceramic (Multi-layer) |

| Capacitance Range | 1 nF to 10 uF | 1 pF to 100 uF |

| Voltage Rating | Up to 630 V | Up to 3 kV |

| Tolerance | +-5% to +-10% | +-1% to +-20% |

| Temperature Stability | Moderate (-55degC to 85degC) | High (-55degC to 125degC) |

| ESR (Equivalent Series Resistance) | Low | Very Low |

| Applications | Audio circuits, timing, filters | High-frequency, RF circuits, decoupling |

| Cost | Moderate | Low to Moderate |

| Physical Size | Larger | Compact |

Introduction to Mylar and Ceramic Capacitors

Mylar capacitors, made from biaxially-oriented polyethylene terephthalate (PET) film, offer excellent electrical stability and low dielectric absorption, making them ideal for precision applications. Ceramic capacitors utilize ceramic materials as the dielectric, providing high capacitance values in compact sizes but with higher dielectric losses compared to Mylar capacitors. Both types serve crucial roles in electronic circuits, where Mylar capacitors excel in low-frequency filtering and timing, while ceramic capacitors are preferred for high-frequency and decoupling applications.

Material Composition: Mylar vs Ceramic

Mylar capacitors use polyethylene terephthalate film as their dielectric material, offering high stability, low moisture absorption, and excellent insulation properties, which contribute to reliable performance in audio and timing applications. Ceramic capacitors utilize ceramic compounds as the dielectric, providing high permittivity and compact size but often exhibiting greater temperature and voltage coefficient variations. The choice between Mylar and ceramic materials impacts dielectric constant, loss tangent, and overall capacitor behavior under environmental stress, influencing application-specific performance outcomes.

Key Electrical Properties Comparison

Mylar capacitors exhibit stable capacitance with low dielectric absorption and low equivalent series resistance (ESR), making them ideal for precision analog circuits and signal filtering. Ceramic capacitors typically offer higher capacitance values and superior high-frequency performance but can suffer from capacitance variability due to temperature and voltage changes. The dielectric constant of Mylar materials ensures consistent electrical characteristics, whereas ceramic dielectrics vary widely, impacting overall circuit stability and noise levels.

Capacitance Stability and Performance

Mylar capacitors exhibit superior capacitance stability compared to ceramic capacitors, maintaining consistent performance under varying temperature and voltage conditions. Their polyester film dielectric minimizes dielectric absorption and leakage current, resulting in reliable signal filtering and timing applications. In contrast, ceramic capacitors can experience capacitance drift and non-linear behavior, especially in high-frequency or high-voltage environments.

Voltage Ratings: Which Is Superior?

Mylar capacitors typically offer higher voltage ratings, often exceeding 600 volts, making them ideal for high-voltage applications requiring stable performance. Ceramic capacitors generally have lower voltage ratings, commonly up to 50-100 volts, though some specialized types can reach higher voltages. Voltage rating superiority depends on the application, with Mylar capacitors preferred for high-voltage requirements and ceramics favored in low to moderate voltage circuits.

Temperature Coefficient Variations

Mylar capacitors exhibit a relatively stable temperature coefficient, typically around +150 ppm/degC, which ensures consistent capacitance under moderate temperature fluctuations. In contrast, ceramic capacitors, especially Class II types like X7R or Y5V, have much higher temperature coefficient variations, sometimes reaching +-15% capacitance change over their rated temperature range. These differences make Mylar capacitors preferable in applications requiring predictable capacitance with temperature stability, while ceramic capacitors suit designs where capacitance tolerance is less critical.

Size and Form Factor Considerations

Mylar capacitors typically offer larger physical sizes due to their film-based construction, making them less suitable for compact circuit designs compared to ceramic capacitors, which are known for their small, surface-mountable form factors ideal for miniaturized electronics. The bulkier profile of Mylar capacitors can limit their application in space-constrained environments, whereas ceramic capacitors excel in high-density circuit boards requiring minimal footprint. Designers prioritize ceramic capacitors when size and form factor are critical, whereas Mylar capacitors are chosen for applications demanding stable capacitance and voltage handling despite their larger size.

Applications: Where Each Capacitor Excels

Mylar capacitors excel in high-frequency circuits and audio applications due to their low dielectric absorption and excellent stability over temperature, making them ideal for precision timing and filtering tasks. Ceramic capacitors are preferred in high-voltage, high-frequency applications such as RF circuits and decoupling because of their small size, low equivalent series resistance (ESR), and ability to handle high ripple currents. Their respective dielectric properties determine their optimal use: Mylar's polyester film provides reliability in analog signal paths, while ceramic's multilayer composition supports compact designs and fast transient response in digital circuits.

Longevity and Reliability Factors

Mylar capacitors exhibit superior longevity and reliability due to their stable dielectric properties and resistance to moisture and temperature variations, making them ideal for long-term applications. Ceramic capacitors, while cost-effective and compact, often face challenges such as micro-cracking and piezoelectric effects that can reduce reliability over time. In high-stress or precision environments, Mylar capacitors offer consistent performance and extended operational lifespan compared to ceramic counterparts.

Cost Analysis: Mylar Versus Ceramic Capacitors

Mylar capacitors generally offer a lower initial cost compared to ceramic capacitors, especially in larger capacitance values where ceramic types become more expensive due to complex manufacturing processes. Despite ceramic capacitors having a smaller footprint and higher voltage ratings, Mylar capacitors provide better cost efficiency in bulk applications with stable capacitance over time. When analyzing total cost of ownership, Mylar capacitors require less frequent replacements in environments with mechanical stress, reducing long-term expenses in industrial and audio applications.

Mylar Capacitors vs Ceramic Capacitors Infographic

materialdif.com

materialdif.com