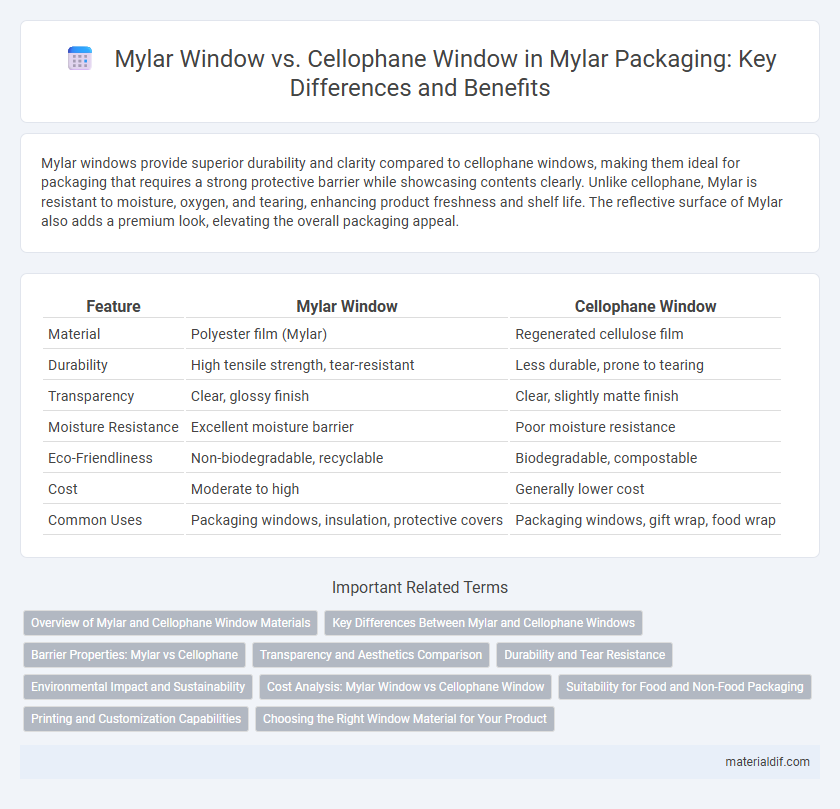

Mylar windows provide superior durability and clarity compared to cellophane windows, making them ideal for packaging that requires a strong protective barrier while showcasing contents clearly. Unlike cellophane, Mylar is resistant to moisture, oxygen, and tearing, enhancing product freshness and shelf life. The reflective surface of Mylar also adds a premium look, elevating the overall packaging appeal.

Table of Comparison

| Feature | Mylar Window | Cellophane Window |

|---|---|---|

| Material | Polyester film (Mylar) | Regenerated cellulose film |

| Durability | High tensile strength, tear-resistant | Less durable, prone to tearing |

| Transparency | Clear, glossy finish | Clear, slightly matte finish |

| Moisture Resistance | Excellent moisture barrier | Poor moisture resistance |

| Eco-Friendliness | Non-biodegradable, recyclable | Biodegradable, compostable |

| Cost | Moderate to high | Generally lower cost |

| Common Uses | Packaging windows, insulation, protective covers | Packaging windows, gift wrap, food wrap |

Overview of Mylar and Cellophane Window Materials

Mylar windows are made from biaxially-oriented polyethylene terephthalate (BoPET), offering superior durability, clarity, and moisture resistance compared to cellophane windows, which are crafted from regenerated cellulose and tend to be more fragile and less moisture-resistant. Mylar's synthetic polymer structure provides enhanced tensile strength and dimensional stability, making it ideal for packaging that requires a clear, strong barrier. In contrast, cellophane windows excel in biodegradability and offer a natural, breathable option, although they lack the longevity and protective properties of Mylar.

Key Differences Between Mylar and Cellophane Windows

Mylar windows offer superior durability and moisture resistance compared to cellophane windows, making them ideal for long-term packaging applications. Unlike the biodegradable but fragile cellophane, Mylar provides a clear, tear-resistant barrier that maintains product visibility while extending shelf life. The key differences lie in Mylar's synthetic polyester composition versus cellophane's cellulose base, resulting in enhanced strength and airtight sealing capabilities.

Barrier Properties: Mylar vs Cellophane

Mylar exhibits superior barrier properties compared to cellophane due to its polyester composition, which provides excellent resistance to moisture, oxygen, and chemicals. Cellophane is biodegradable but offers limited protection against water vapor and gases, making it less effective in preserving product freshness. Mylar's enhanced impermeability ensures longer shelf life and better protection in packaging applications.

Transparency and Aesthetics Comparison

Mylar windows offer superior transparency compared to cellophane, providing a clearer and more durable view ideal for high-quality packaging. Cellophane windows tend to have a slightly cloudy appearance and are less resistant to moisture and tearing, which can affect the overall aesthetic appeal. The smooth, glossy finish of Mylar enhances visual clarity and product presentation, making it the preferred choice for premium packaging applications.

Durability and Tear Resistance

Mylar windows exhibit superior durability and tear resistance compared to cellophane windows, making them ideal for applications requiring long-lasting performance. Mylar's polyester film composition resists punctures and abrasions, maintaining clarity and structural integrity under stress. Cellophane, being more delicate and prone to tearing, is less suitable for packaging that demands robust protection.

Environmental Impact and Sustainability

Mylar windows, made from biaxially-oriented polyethylene terephthalate (BoPET), offer superior durability and recyclability compared to cellophane windows derived from cellulose, which often degrade faster and have limited recyclability. The production of Mylar involves fewer natural resource inputs and generates lower greenhouse gas emissions, enhancing its sustainability profile. Mylar's high resistance to moisture and oxygen also reduces product spoilage, contributing to waste reduction in packaging applications.

Cost Analysis: Mylar Window vs Cellophane Window

Mylar windows generally cost more upfront than cellophane windows due to higher material and manufacturing expenses, but their superior durability and resistance to tearing often result in lower replacement and maintenance costs over time. Cellophane windows are less expensive initially but tend to degrade faster, incurring more frequent replacement expenses. Evaluating total cost of ownership, Mylar offers better long-term value despite a higher initial investment.

Suitability for Food and Non-Food Packaging

Mylar windows offer superior moisture and oxygen barrier properties compared to cellophane windows, making them highly suitable for food packaging where preservation and freshness are crucial. Cellophane windows provide biodegradability but lack the durability and barrier efficiency required for long-term food storage, making them more appropriate for non-food packaging applications. Mylar's heat-sealing capability ensures airtight packaging, enhancing shelf life and product protection in both food and non-food industries.

Printing and Customization Capabilities

Mylar windows offer superior printing quality and customization capabilities compared to cellophane windows, enabling sharp, vibrant graphics and detailed brand logos that enhance product appeal. Mylar's durability and heat-resistant properties allow for advanced printing techniques such as foil stamping and embossing, which are not feasible with cellophane. Custom shapes, sizes, and finishes can be easily achieved with Mylar, providing versatile design options for packaging that meet various marketing requirements.

Choosing the Right Window Material for Your Product

Mylar window films offer superior durability, moisture resistance, and clarity compared to cellophane, making them ideal for packaging that requires long-term protection and visibility. Cellophane windows are biodegradable and provide excellent breathability, suitable for eco-friendly and perishable products. Selecting between Mylar and cellophane windows depends on balancing product preservation needs with environmental impact priorities.

Mylar Window vs Cellophane Window Infographic

materialdif.com

materialdif.com