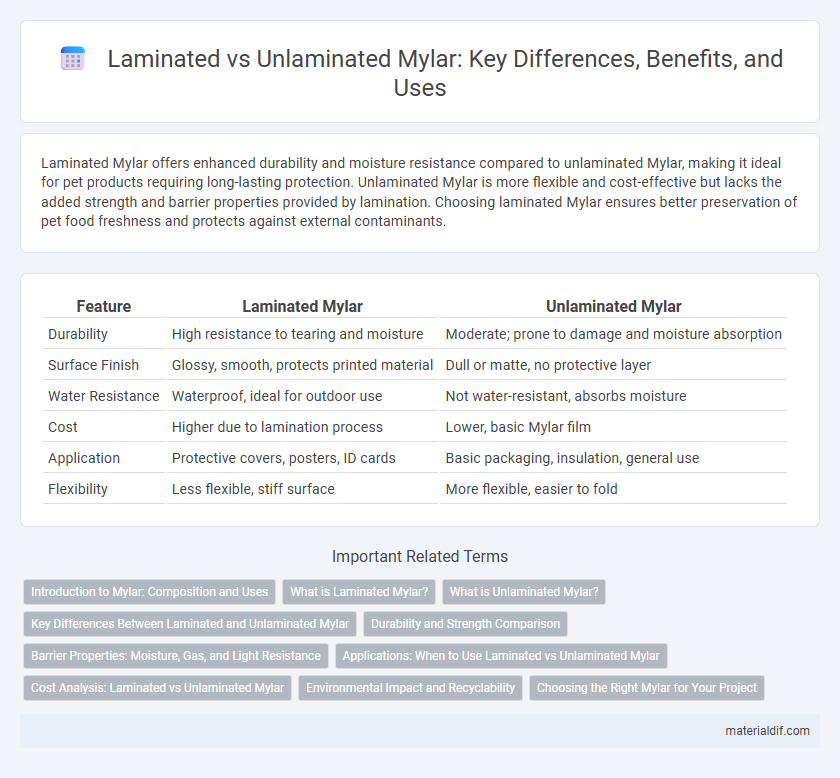

Laminated Mylar offers enhanced durability and moisture resistance compared to unlaminated Mylar, making it ideal for pet products requiring long-lasting protection. Unlaminated Mylar is more flexible and cost-effective but lacks the added strength and barrier properties provided by lamination. Choosing laminated Mylar ensures better preservation of pet food freshness and protects against external contaminants.

Table of Comparison

| Feature | Laminated Mylar | Unlaminated Mylar |

|---|---|---|

| Durability | High resistance to tearing and moisture | Moderate; prone to damage and moisture absorption |

| Surface Finish | Glossy, smooth, protects printed material | Dull or matte, no protective layer |

| Water Resistance | Waterproof, ideal for outdoor use | Not water-resistant, absorbs moisture |

| Cost | Higher due to lamination process | Lower, basic Mylar film |

| Application | Protective covers, posters, ID cards | Basic packaging, insulation, general use |

| Flexibility | Less flexible, stiff surface | More flexible, easier to fold |

Introduction to Mylar: Composition and Uses

Mylar is a polyester film known for its tensile strength, chemical stability, and reflective properties, commonly made from polyethylene terephthalate (PET). Laminated Mylar consists of multiple layers bonded together, enhancing durability, moisture resistance, and optical clarity, making it ideal for packaging, insulation, and graphic arts applications. Unlaminated Mylar, being a single-layer film, offers flexibility and cost-effectiveness for uses such as electrical insulation, balloons, and emergency blankets.

What is Laminated Mylar?

Laminated Mylar is a type of polyester film coated with a protective plastic layer, enhancing durability and resistance to moisture, chemicals, and abrasions compared to unlaminated Mylar. This lamination process improves tensile strength and provides a glossy or matte finish, making laminated Mylar ideal for high-quality printing, insulation, and packaging applications. Unlaminated Mylar lacks this protective layer, making it more susceptible to damage and less suitable for demanding environments.

What is Unlaminated Mylar?

Unlaminated Mylar is a single-layer polyester film known for its strength, clarity, and resistance to moisture, chemicals, and temperature variations. It lacks the protective outer coating found in laminated Mylar, making it more susceptible to scratches and damage but more flexible for specific applications. Commonly used in insulation, packaging, and art projects, unlaminated Mylar provides essential durability without the added rigidity or gloss of lamination.

Key Differences Between Laminated and Unlaminated Mylar

Laminated Mylar features a protective coating that enhances durability, water resistance, and tear strength, making it ideal for long-term preservation and packaging applications. Unlaminated Mylar lacks this additional layer, resulting in a thinner, more flexible material that offers less protection but greater ease of handling for short-term uses. The key differences between laminated and unlaminated Mylar lie in their durability, moisture resistance, and suitability for different environmental conditions.

Durability and Strength Comparison

Laminated Mylar offers superior durability and strength compared to unlaminated Mylar due to its added protective layer that enhances resistance to tearing, moisture, and UV exposure. Unlaminated Mylar, while flexible and lightweight, is more prone to damage from abrasion and environmental factors. Choosing laminated Mylar is ideal for applications requiring prolonged durability and structural integrity.

Barrier Properties: Moisture, Gas, and Light Resistance

Laminated Mylar offers superior barrier properties compared to unlaminated Mylar, providing enhanced moisture resistance that prevents water vapor penetration more effectively. Its multiple layers significantly improve gas barrier capabilities, reducing oxygen transmission rates to protect sensitive contents. Furthermore, laminated Mylar demonstrates increased light resistance, blocking UV and visible light to maintain product integrity and extend shelf life.

Applications: When to Use Laminated vs Unlaminated Mylar

Laminated Mylar offers enhanced durability and moisture resistance, making it ideal for outdoor banners, archival documents, and product packaging requiring long-term protection. Unlaminated Mylar suits applications where flexibility and breathability are essential, such as overhead projector sheets, stencils, and temporary protective covers. Choosing between laminated and unlaminated Mylar depends on the need for structural strength versus lightweight, adaptable material properties.

Cost Analysis: Laminated vs Unlaminated Mylar

Laminated Mylar typically incurs higher production costs due to the additional lamination process, which enhances durability and resistance to moisture and UV exposure. Unlaminated Mylar remains more cost-effective as it eliminates these extra manufacturing steps but offers less protection and longevity. When conducting a cost analysis, consider long-term savings from laminated Mylar's extended lifespan against the initial expense, especially for applications requiring strength and environmental resistance.

Environmental Impact and Recyclability

Laminated Mylar contains multiple bonded layers, which complicates recycling due to the difficulty in separating materials and increases its environmental footprint compared to unlaminated Mylar. Unlaminated Mylar is more environmentally friendly because it consists of a single polyester layer, making it easier to recycle and reducing landfill waste. Choosing unlaminated Mylar supports sustainability efforts by minimizing resource consumption and enhancing material recovery processes.

Choosing the Right Mylar for Your Project

Laminated Mylar offers enhanced durability and moisture resistance, making it ideal for projects requiring long-term protection and strength. Unlaminated Mylar provides greater flexibility and a thinner profile, suitable for applications where lightweight material and clarity are priorities. Choosing the right Mylar depends on balancing factors such as exposure conditions, desired longevity, and specific project requirements to optimize performance.

Laminated Mylar vs Unlaminated Mylar Infographic

materialdif.com

materialdif.com