Mylar thickness typically ranges from 12 to 125 microns, offering excellent tensile strength and flexibility, while polyimide films are usually thinner, starting around 7 microns but providing superior thermal stability and chemical resistance. The choice between Mylar and polyimide thickness depends on application requirements, with Mylar being favored for durability and cost-effectiveness, whereas polyimide suits high-temperature or electrically demanding environments. Optimizing film thickness enhances performance, balancing mechanical protection with flexibility and thermal endurance.

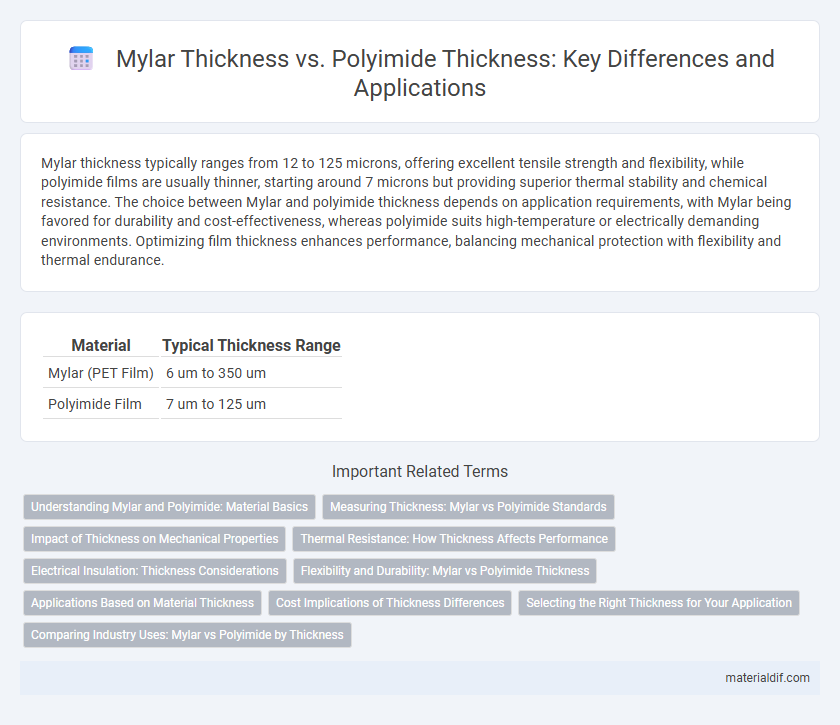

Table of Comparison

| Material | Typical Thickness Range |

|---|---|

| Mylar (PET Film) | 6 um to 350 um |

| Polyimide Film | 7 um to 125 um |

Understanding Mylar and Polyimide: Material Basics

Mylar thickness typically ranges from 4 to 125 microns, offering versatile applications in insulation and packaging, while polyimide films generally vary between 12 to 50 microns and are known for their superior thermal stability and chemical resistance. Mylar, a form of biaxially-oriented polyethylene terephthalate (BoPET), exhibits excellent tensile strength and dimensional stability compared to polyimide, which excels in high-temperature environments up to 400degC. Understanding these thickness properties helps engineers select the appropriate film based on mechanical strength for Mylar or thermal endurance for polyimide in electronic and industrial applications.

Measuring Thickness: Mylar vs Polyimide Standards

Mylar thickness typically ranges from 12 to 200 microns, while polyimide films commonly measure between 25 to 125 microns, reflecting industry-specific applications. Measuring thickness for Mylar follows ASTM D374 and ASTM E252 standards, whereas polyimide thickness measurement adheres to ASTM D374 and IPC-TM-650 methods for precision. Accurate thickness measurement impacts electrical insulation properties and mechanical strength, making adherence to these standards crucial for quality control in flexible electronics and packaging industries.

Impact of Thickness on Mechanical Properties

Mylar thickness directly influences its tensile strength and flexibility, with thicker Mylar films exhibiting enhanced durability and resistance to tearing compared to thinner variants. In contrast, polyimide thickness impacts thermal stability and mechanical resilience, where increased thickness improves its ability to withstand higher temperatures and mechanical stress without deformation. Understanding these differences in thickness-related mechanical properties is crucial for selecting the appropriate material in applications requiring precise strength and flexibility balances.

Thermal Resistance: How Thickness Affects Performance

Mylar thickness generally ranges from 12 to 125 microns, while polyimide films vary between 12 to 50 microns, with thicker films providing enhanced thermal resistance due to increased insulating properties. Polyimide exhibits superior thermal stability up to 400degC, outperforming Mylar, whose optimum thermal resistance typically peaks around 150degC, making polyimide preferable for high-temperature applications. The thicker the film, the greater the thermal barrier effect, but the intrinsic thermal properties of polyimide make even thinner layers more effective than thicker Mylar in resisting heat.

Electrical Insulation: Thickness Considerations

Mylar thickness typically ranges from 12 to 250 microns, offering reliable electrical insulation due to its uniform dielectric strength, whereas polyimide films generally vary from 25 to 125 microns, providing superior thermal stability and dielectric constant for high-performance applications. Choosing the appropriate thickness is crucial as Mylar's higher dielectric breakdown voltage at thinner gauges often suits standard insulation needs, while polyimide's excellent insulation performance at lower thicknesses is ideal for compact, high-temperature electronics. Engineers must balance Mylar's cost-effectiveness and mechanical properties against polyimide's enhanced electrical insulation capabilities when specifying material thickness for optimal dielectric performance.

Flexibility and Durability: Mylar vs Polyimide Thickness

Mylar films typically range in thickness from 12 to 50 microns, offering excellent flexibility and moderate durability ideal for lightweight applications. Polyimide films, generally thicker at 25 to 150 microns, provide superior thermal stability and enhanced mechanical strength while maintaining flexibility. Increasing thickness enhances durability in both materials, but polyimide's chemical resistance and heat tolerance make it preferable for demanding environments requiring robust, flexible substrates.

Applications Based on Material Thickness

Mylar thickness typically ranges from 12 to 250 microns, providing excellent barrier properties and electrical insulation for flexible packaging, insulation films, and capacitors, while polyimide films, usually between 7 to 125 microns, offer superior thermal stability and chemical resistance, ideal for high-temperature electronics, aerospace components, and flexible printed circuit boards. Applications requiring lightweight, transparent insulation often use thinner Mylar films, whereas polyimide films are favored in environments demanding durability under extreme heat and mechanical stress. Selecting material thickness balances flexibility, mechanical strength, and thermal performance to match specific industrial and electronic use cases.

Cost Implications of Thickness Differences

Mylar thickness variations significantly impact material costs, with thicker Mylar films generally being more expensive due to increased raw material usage. Polyimide films, although typically more costly per unit thickness because of their superior thermal and chemical resistance, may offer cost savings in thinner gauges by reducing overall material volume. Choosing between Mylar and polyimide thickness involves balancing initial material costs against performance benefits and application-specific requirements.

Selecting the Right Thickness for Your Application

Selecting the right thickness for Mylar versus polyimide depends primarily on the application's mechanical, thermal, and electrical requirements. Mylar typically ranges from 1 mil (25 microns) to 10 mil (254 microns), offering excellent tensile strength and dimensional stability, while polyimide films vary from 0.5 mil (12.7 microns) to 5 mil (127 microns), known for superior heat resistance and chemical stability. Choosing the optimal thickness balances flexibility, durability, and insulation properties to ensure performance in electronics, insulation, or protective layering.

Comparing Industry Uses: Mylar vs Polyimide by Thickness

Mylar typically ranges from 12 to 125 microns in thickness, preferred in packaging and insulation applications due to its high tensile strength and dimensional stability. Polyimide films, often available between 12 and 75 microns, are chosen for electronic and aerospace industries for their superior heat resistance and dielectric properties. The thickness variation influences industry use, with Mylar favoring thicker films for robust mechanical protection, while thinner polyimide films excel in high-temperature and flexible circuit applications.

Mylar Thickness vs Polyimide Thickness Infographic

materialdif.com

materialdif.com