Mylar tape offers superior flexibility and durability compared to aluminum tape, making it ideal for applications requiring repeated bending and stretching. Unlike aluminum tape, Mylar provides excellent resistance to moisture, chemicals, and UV exposure, ensuring long-lasting performance in harsh environments. While aluminum tape excels in heat reflection and electrical conductivity, Mylar tape is preferred for insulating, labeling, and protective wraps in electronics and aerospace industries.

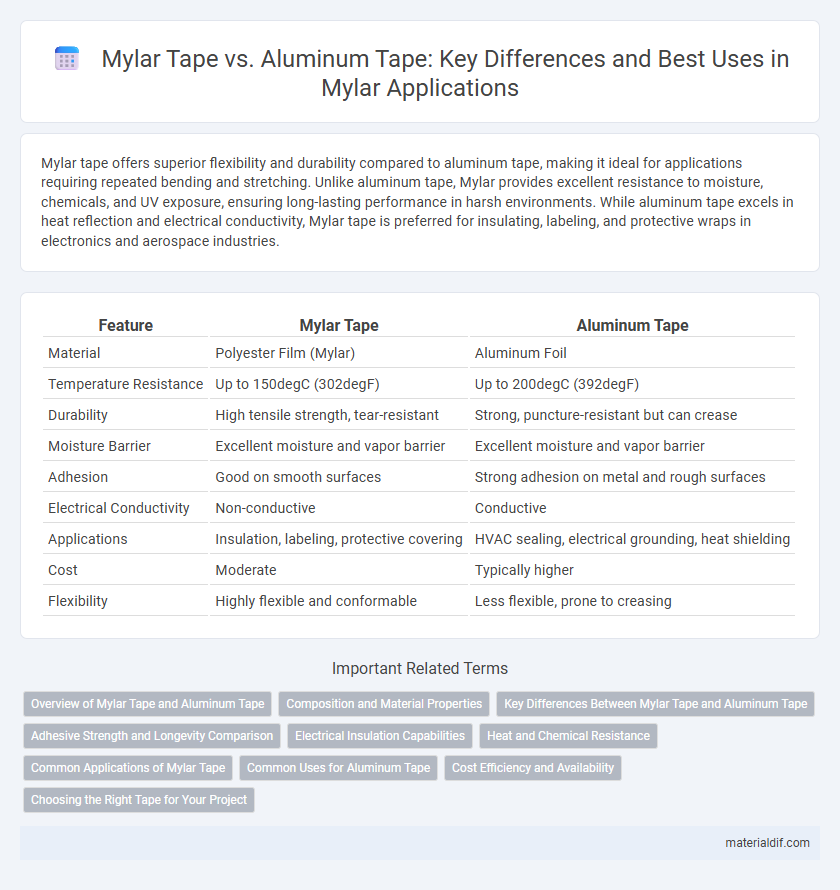

Table of Comparison

| Feature | Mylar Tape | Aluminum Tape |

|---|---|---|

| Material | Polyester Film (Mylar) | Aluminum Foil |

| Temperature Resistance | Up to 150degC (302degF) | Up to 200degC (392degF) |

| Durability | High tensile strength, tear-resistant | Strong, puncture-resistant but can crease |

| Moisture Barrier | Excellent moisture and vapor barrier | Excellent moisture and vapor barrier |

| Adhesion | Good on smooth surfaces | Strong adhesion on metal and rough surfaces |

| Electrical Conductivity | Non-conductive | Conductive |

| Applications | Insulation, labeling, protective covering | HVAC sealing, electrical grounding, heat shielding |

| Cost | Moderate | Typically higher |

| Flexibility | Highly flexible and conformable | Less flexible, prone to creasing |

Overview of Mylar Tape and Aluminum Tape

Mylar tape consists of a polyester film backing that provides excellent tensile strength, electrical insulation, and resistance to moisture, chemicals, and heat, making it ideal for electrical and insulation applications. Aluminum tape features a metal foil backing offering superior thermal conductivity, reflectivity, and durability, often used for sealing HVAC ducts and providing moisture and UV resistance. Both tapes serve distinct purposes: Mylar tape excels in insulation and electrical uses, while aluminum tape is preferred for thermal management and weatherproof sealing.

Composition and Material Properties

Mylar tape consists of a biaxially-oriented polyethylene terephthalate (PET) film coated with pressure-sensitive adhesive, offering high tensile strength, flexibility, and excellent electrical insulation properties. Aluminum tape features a thin aluminum foil backing combined with an adhesive layer, providing superior heat resistance, moisture barrier, and reflectivity. The polymer base of Mylar tape makes it lightweight and durable, while aluminum tape delivers enhanced thermal conductivity and corrosion resistance.

Key Differences Between Mylar Tape and Aluminum Tape

Mylar tape features a polyester film backing that offers exceptional tensile strength, flexibility, and resistance to moisture, making it suitable for electrical insulation and long-term labeling. In contrast, aluminum tape incorporates a metal foil backing that provides superior heat reflectivity, conductivity, and durability against extreme temperatures, ideal for HVAC sealing and metal surface repairs. The key differences lie in Mylar's non-conductive, lightweight properties versus aluminum tape's conductive, heat-resistant characteristics, influencing their specific industrial applications and performance.

Adhesive Strength and Longevity Comparison

Mylar tape offers superior adhesive strength compared to aluminum tape due to its polyester film backing, providing excellent resistance to stretching and tearing. The longevity of Mylar tape surpasses aluminum tape as it maintains adhesion under extreme temperatures, UV exposure, and moisture over extended periods. Aluminum tape, while durable, often loses adhesive properties faster when subjected to harsh environmental conditions.

Electrical Insulation Capabilities

Mylar tape offers superior electrical insulation due to its high dielectric strength and resistance to moisture, making it ideal for insulating electrical components. Aluminum tape, while conductive and excellent for shielding and grounding, does not provide the same level of electrical insulation as Mylar. In applications requiring non-conductive insulation and protection from voltage breakdown, Mylar tape is the preferred choice.

Heat and Chemical Resistance

Mylar tape offers superior heat resistance, typically withstanding temperatures up to 260degC (500degF), making it ideal for high-temperature applications. In contrast, aluminum tape has excellent heat reflection properties but generally endures lower temperatures around 150degC (302degF). Chemically, Mylar tape exhibits strong resistance to solvents and oils due to its polyester film composition, whereas aluminum tape is more susceptible to corrosion and chemical degradation in harsh environments.

Common Applications of Mylar Tape

Mylar tape is widely used in electrical insulation, thermal insulation, and packaging due to its high tensile strength and excellent resistance to heat and chemicals. It is commonly applied in securing wires and cables, insulating transformers, and protecting sensitive electronic components. Unlike aluminum tape, Mylar tape offers superior flexibility and durability in environments requiring electrical isolation and moisture resistance.

Common Uses for Aluminum Tape

Aluminum tape is commonly used for sealing and insulating HVAC ducts, providing excellent thermal conductivity and resistance to moisture and chemicals. It is ideal for repairing metal surfaces, joining metal pipes, and wrapping cables to protect against corrosion and wear. Mylar tape, by contrast, is often favored for its electrical insulation and reflective properties, but aluminum tape excels in heavy-duty industrial and construction applications.

Cost Efficiency and Availability

Mylar tape offers greater cost efficiency due to its lower material and production expenses compared to aluminum tape, making it ideal for large-scale insulation and packaging applications. It is widely available in various thicknesses and adhesive types, ensuring easy procurement from multiple suppliers globally. Aluminum tape, while more expensive, is less readily available in diverse forms, which can impact overall project budgets and timelines.

Choosing the Right Tape for Your Project

Mylar tape offers superior flexibility, heat resistance, and electrical insulation, making it ideal for applications requiring durability and non-conductive properties, such as electronics and thermal insulation. Aluminum tape provides excellent conductivity, moisture resistance, and strong adhesion for HVAC systems, duct sealing, and reflective insulation tasks. Selecting the right tape depends on project-specific needs like thermal performance, electrical insulation, and environmental exposure.

Mylar Tape vs Aluminum Tape Infographic

materialdif.com

materialdif.com