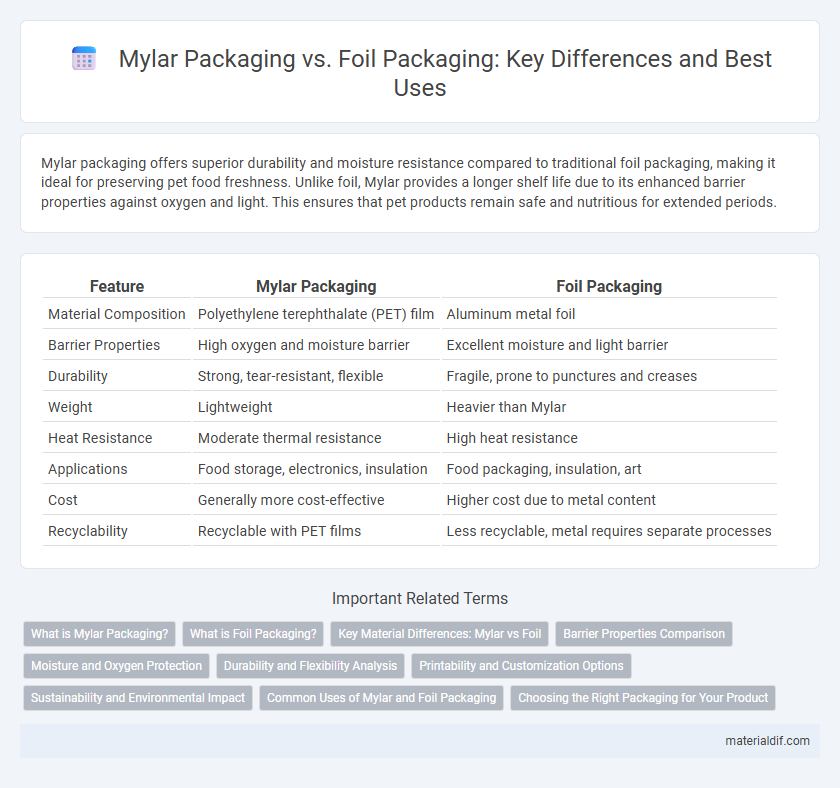

Mylar packaging offers superior durability and moisture resistance compared to traditional foil packaging, making it ideal for preserving pet food freshness. Unlike foil, Mylar provides a longer shelf life due to its enhanced barrier properties against oxygen and light. This ensures that pet products remain safe and nutritious for extended periods.

Table of Comparison

| Feature | Mylar Packaging | Foil Packaging |

|---|---|---|

| Material Composition | Polyethylene terephthalate (PET) film | Aluminum metal foil |

| Barrier Properties | High oxygen and moisture barrier | Excellent moisture and light barrier |

| Durability | Strong, tear-resistant, flexible | Fragile, prone to punctures and creases |

| Weight | Lightweight | Heavier than Mylar |

| Heat Resistance | Moderate thermal resistance | High heat resistance |

| Applications | Food storage, electronics, insulation | Food packaging, insulation, art |

| Cost | Generally more cost-effective | Higher cost due to metal content |

| Recyclability | Recyclable with PET films | Less recyclable, metal requires separate processes |

What is Mylar Packaging?

Mylar packaging is a type of flexible packaging made from biaxially-oriented polyethylene terephthalate (BoPET), known for its high tensile strength, chemical stability, and excellent barrier properties against moisture, gases, and light. Unlike traditional foil packaging, which primarily consists of aluminum, Mylar offers superior durability and resistance to punctures and tears, making it ideal for preserving food freshness and extending shelf life. Its transparent or metallized film options provide versatile applications in food, pharmaceuticals, and electronics packaging, combining visual appeal with functional protection.

What is Foil Packaging?

Foil packaging consists of thin layers of aluminum that provide excellent barriers against moisture, light, and oxygen, ensuring product freshness and extended shelf life. It is highly flexible, heat-resistant, and commonly used for food, pharmaceuticals, and cosmetics. The material's multi-layer construction enables superior protection compared to other packaging options like Mylar.

Key Material Differences: Mylar vs Foil

Mylar packaging utilizes biaxially-oriented polyethylene terephthalate (BoPET), known for its high tensile strength, clarity, and excellent barrier properties against moisture and oxygen. Foil packaging typically consists of aluminum foil, providing superior light and gas impermeability but lacking the flexibility and puncture resistance offered by Mylar films. These material differences impact the durability, protection level, and suitability for various food and pharmaceutical packaging applications.

Barrier Properties Comparison

Mylar packaging offers superior barrier properties against moisture, oxygen, and UV light compared to traditional foil packaging, ensuring extended shelf life for perishable products. The polyester film in Mylar provides enhanced puncture resistance and dimensional stability, while foil packaging primarily relies on its metal layer for protection but can be prone to creasing and pinholes. These attributes make Mylar an optimal choice for applications requiring reliable contamination prevention and preservation of product integrity.

Moisture and Oxygen Protection

Mylar packaging provides superior moisture and oxygen barrier properties compared to traditional foil packaging, making it ideal for preserving the freshness and shelf life of sensitive products. The multi-layer polyester composition of Mylar effectively blocks water vapor and oxygen transmission, reducing the risk of spoilage and degradation. Foil packaging, while offering good oxygen resistance, is more prone to pinholes and moisture permeability, limiting its effectiveness in long-term protection.

Durability and Flexibility Analysis

Mylar packaging offers superior durability compared to traditional foil packaging due to its resistance to punctures, moisture, and chemical degradation, making it ideal for long-term storage and protection. Its flexibility allows it to conform tightly around products without tearing, enhancing product preservation and shelf appeal. In contrast, foil packaging is more prone to cracking and less adaptable to complex shapes, limiting its effectiveness in dynamic packaging environments.

Printability and Customization Options

Mylar packaging offers superior printability due to its smooth surface, allowing for high-resolution graphics and vibrant colors that enhance brand visibility. It supports diverse customization options including matte, gloss, metallic finishes, and various thicknesses, making it versatile for different product needs. In contrast, foil packaging often has limited print clarity and fewer customization choices, primarily focusing on barrier properties rather than aesthetic appeal.

Sustainability and Environmental Impact

Mylar packaging offers enhanced recyclability compared to traditional foil packaging due to its polyester film composition, which is more environmentally friendly and less energy-intensive to produce. Foil packaging, often made from aluminum, has a substantial carbon footprint due to mining and refining processes, though it is fully recyclable in industrial recycling streams. Choosing Mylar packaging supports sustainability goals by reducing resource consumption and promoting lower greenhouse gas emissions throughout the product lifecycle.

Common Uses of Mylar and Foil Packaging

Mylar packaging is widely used for food storage, pharmaceutical protection, and electronic component shielding due to its high tensile strength and excellent barrier properties against moisture and oxygen. Foil packaging, commonly made from aluminum, excels in preserving perishable goods, pharmaceuticals, and baked products by providing an effective barrier against light, air, and contaminants. Both materials are essential in packaging industries for maintaining product freshness and extending shelf life, with Mylar favored for flexibility and thermal resistance, while foil is preferred for its superior barrier to light and odor.

Choosing the Right Packaging for Your Product

Mylar packaging offers superior moisture and oxygen barrier properties compared to foil packaging, making it ideal for preserving freshness and extending shelf life of food products. Its lightweight and flexible structure reduces shipping costs and enhances product presentation, while foil packaging provides excellent heat resistance suitable for high-temperature applications. Selecting the right packaging depends on factors such as product sensitivity, storage conditions, and desired shelf life to maximize protection and maintain quality.

Mylar Packaging vs Foil Packaging Infographic

materialdif.com

materialdif.com