Mylar wrap offers superior barrier properties compared to LDPE wrap, providing enhanced protection against moisture, oxygen, and light, which extends the shelf life of pet products. While LDPE wrap is more flexible and cost-effective, it lacks the durability and reflectivity of Mylar, making it less suitable for long-term preservation. Choosing Mylar wrap ensures better freshness retention and product integrity for pet packaging needs.

Table of Comparison

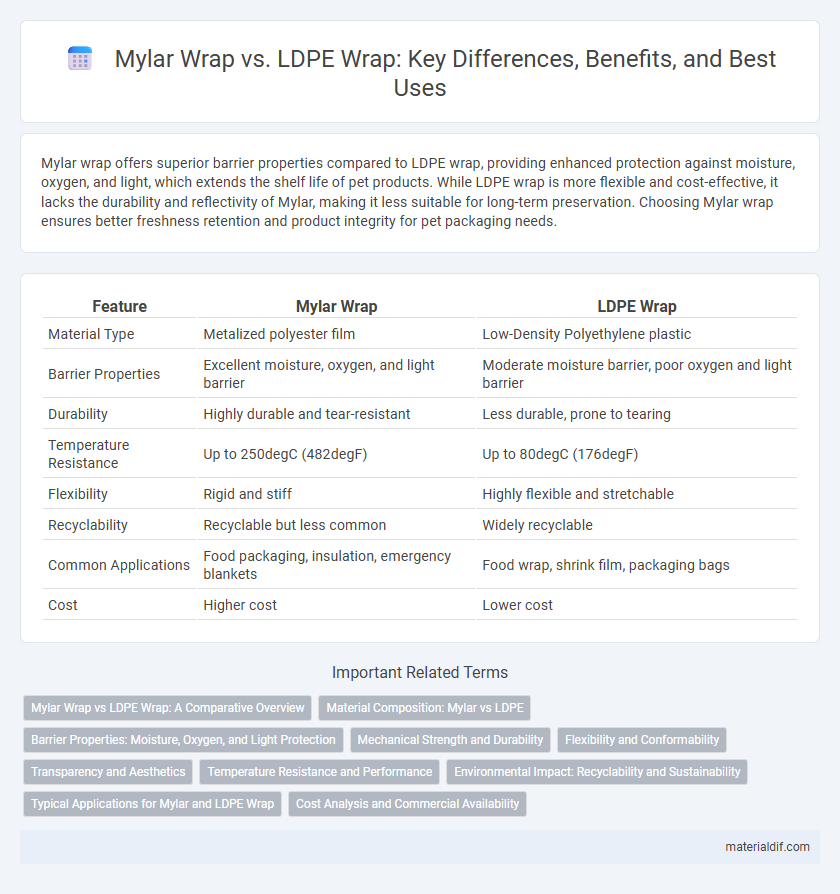

| Feature | Mylar Wrap | LDPE Wrap |

|---|---|---|

| Material Type | Metalized polyester film | Low-Density Polyethylene plastic |

| Barrier Properties | Excellent moisture, oxygen, and light barrier | Moderate moisture barrier, poor oxygen and light barrier |

| Durability | Highly durable and tear-resistant | Less durable, prone to tearing |

| Temperature Resistance | Up to 250degC (482degF) | Up to 80degC (176degF) |

| Flexibility | Rigid and stiff | Highly flexible and stretchable |

| Recyclability | Recyclable but less common | Widely recyclable |

| Common Applications | Food packaging, insulation, emergency blankets | Food wrap, shrink film, packaging bags |

| Cost | Higher cost | Lower cost |

Mylar Wrap vs LDPE Wrap: A Comparative Overview

Mylar wrap offers superior barrier properties against moisture, oxygen, and light compared to LDPE wrap, making it ideal for long-term food storage and preservation. Its metallic polyester film provides higher tensile strength and thermal stability, while LDPE wrap is more flexible and cost-effective but less durable and permeable to gases. Choosing between Mylar and LDPE wraps depends on specific needs for durability, protection, and budget constraints.

Material Composition: Mylar vs LDPE

Mylar wrap is made from biaxially oriented polyethylene terephthalate (BoPET), offering superior tensile strength, clarity, and chemical resistance compared to LDPE wrap, which is composed of low-density polyethylene, known for its flexibility and lower production cost. The crystalline structure of Mylar provides enhanced durability and barrier properties against moisture, gases, and UV light, making it ideal for long-term preservation. In contrast, LDPE's amorphous polymer chain structure results in a softer, more elastic film but offers less protection and mechanical resistance than Mylar.

Barrier Properties: Moisture, Oxygen, and Light Protection

Mylar wrap offers superior barrier properties compared to LDPE wrap, effectively blocking moisture, oxygen, and light to preserve product freshness and extend shelf life. Its metallized polyester composition provides high impermeability, making it ideal for sensitive goods requiring stringent protection from environmental factors. In contrast, LDPE wrap has moderate moisture resistance but allows more oxygen and light transmission, limiting its use for long-term preservation.

Mechanical Strength and Durability

Mylar wrap exhibits superior mechanical strength compared to LDPE wrap, providing enhanced resistance to tearing and punctures. Its durability under extreme temperatures and UV exposure exceeds that of LDPE, making it ideal for long-term protection and insulation. While LDPE offers flexibility and cost-effectiveness, Mylar's robust tensile strength and resilient polymer structure ensure prolonged performance in demanding applications.

Flexibility and Conformability

Mylar wrap offers superior flexibility and conformability compared to LDPE wrap, making it ideal for applications requiring precise sealing around irregular shapes. Its polyester composition provides enhanced tensile strength and elasticity, allowing it to stretch without tearing while maintaining a tight seal. LDPE wrap tends to be less flexible and more prone to distortion, limiting its effectiveness in tightly conforming to complex surfaces.

Transparency and Aesthetics

Mylar wrap offers superior transparency and a high-gloss finish compared to LDPE wrap, making it ideal for packaging that demands clear visibility and attractive presentation. The smooth, reflective surface of Mylar enhances product appeal by providing a sleek, professional look, while LDPE wrap tends to have a matte or cloudy appearance that can diminish visual clarity. For applications where aesthetic quality and product visibility are critical, Mylar wrap delivers both enhanced transparency and an eye-catching shine.

Temperature Resistance and Performance

Mylar wrap offers superior temperature resistance compared to LDPE wrap, withstanding temperatures up to 150degC while LDPE typically tolerates only around 80degC. This high thermal durability makes Mylar ideal for applications involving heat exposure, maintaining integrity without melting or deforming. In performance terms, Mylar provides better barrier properties against moisture, oxygen, and light, enhancing product preservation and shelf life beyond LDPE capabilities.

Environmental Impact: Recyclability and Sustainability

Mylar wrap, made from biaxially-oriented polyethylene terephthalate (BoPET), offers limited recyclability due to its mixed plastic composition, often requiring specialized recycling facilities. LDPE wrap, composed of low-density polyethylene, is more widely accepted in curbside recycling programs and contributes less environmental burden due to easier recycling processes. Sustainability considerations favor LDPE wraps because they generally have lower production energy demands and degrade more efficiently in controlled environments compared to Mylar's more durable and long-lasting synthetic properties.

Typical Applications for Mylar and LDPE Wrap

Mylar wrap is extensively used in applications requiring high barrier properties such as food packaging, emergency blankets, and insulation due to its excellent moisture, oxygen, and gas barrier capabilities. LDPE wrap finds typical use in household and industrial food wrapping, pallet wrapping, and produce packaging, offering flexibility, transparency, and moisture resistance. Mylar's durability and reflective qualities make it ideal for long-term storage and protective coverings, while LDPE's stretchability caters to everyday convenience and cost-effective packaging solutions.

Cost Analysis and Commercial Availability

Mylar wrap generally costs more than LDPE wrap due to its superior barrier properties and durability, making it a premium option in packaging. LDPE wrap offers greater commercial availability and lower price points, making it suitable for large-scale, cost-sensitive applications. Businesses prioritize Mylar wrap for high-value or moisture-sensitive goods, while LDPE remains preferred for affordable, everyday packaging needs.

Mylar Wrap vs LDPE Wrap Infographic

materialdif.com

materialdif.com