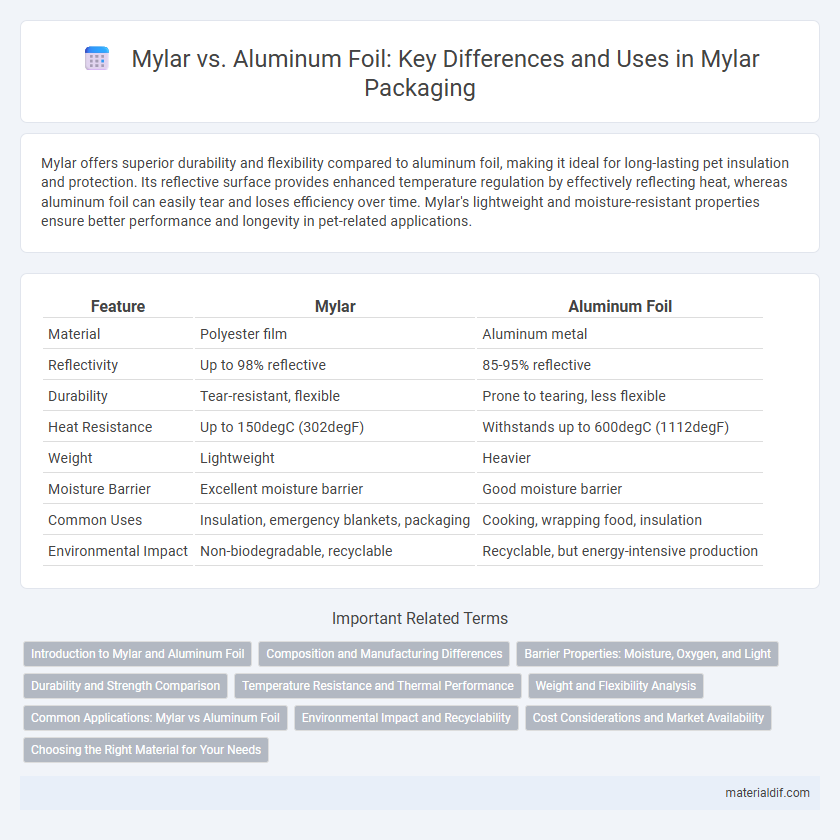

Mylar offers superior durability and flexibility compared to aluminum foil, making it ideal for long-lasting pet insulation and protection. Its reflective surface provides enhanced temperature regulation by effectively reflecting heat, whereas aluminum foil can easily tear and loses efficiency over time. Mylar's lightweight and moisture-resistant properties ensure better performance and longevity in pet-related applications.

Table of Comparison

| Feature | Mylar | Aluminum Foil |

|---|---|---|

| Material | Polyester film | Aluminum metal |

| Reflectivity | Up to 98% reflective | 85-95% reflective |

| Durability | Tear-resistant, flexible | Prone to tearing, less flexible |

| Heat Resistance | Up to 150degC (302degF) | Withstands up to 600degC (1112degF) |

| Weight | Lightweight | Heavier |

| Moisture Barrier | Excellent moisture barrier | Good moisture barrier |

| Common Uses | Insulation, emergency blankets, packaging | Cooking, wrapping food, insulation |

| Environmental Impact | Non-biodegradable, recyclable | Recyclable, but energy-intensive production |

Introduction to Mylar and Aluminum Foil

Mylar is a polyester film known for its durability, flexibility, and reflective properties, commonly used in insulation, packaging, and decorative applications. Aluminum foil, made from thin sheets of aluminum, excels in heat resistance, barrier protection, and malleability, making it ideal for cooking, food storage, and insulation. The distinct material compositions of Mylar and aluminum foil result in different performance characteristics, influencing their suitability for specific industrial and household uses.

Composition and Manufacturing Differences

Mylar is a polyester film made from stretched polyethylene terephthalate (PET), produced through a biaxial orientation process that enhances its strength and clarity. Aluminum foil consists of thin sheets of pure aluminum, created by rolling aluminum slabs into extremely thin layers. The manufacturing process of Mylar involves polymer extrusion and stretching, while aluminum foil is produced via mechanical rolling, resulting in distinct physical properties and uses.

Barrier Properties: Moisture, Oxygen, and Light

Mylar offers superior barrier properties against moisture, oxygen, and light compared to aluminum foil, making it ideal for preserving product freshness and extending shelf life. Its polyester composition provides excellent resistance to water vapor transmission and oxygen permeability, significantly outperforming aluminum foil in preventing contamination and degradation. While aluminum foil blocks light effectively, Mylar's combination of transparency and reflective coatings allows for customizable light protection tailored to specific packaging needs.

Durability and Strength Comparison

Mylar exhibits superior durability and tensile strength compared to aluminum foil, resisting tearing and punctures more effectively under stress. Its polyester composition allows it to maintain structural integrity in extreme temperatures and prolonged exposure to environmental elements. Conversely, aluminum foil is more prone to wrinkling and tearing due to its thin metal structure, reducing its longevity and reliability in packaging or insulation applications.

Temperature Resistance and Thermal Performance

Mylar exhibits superior temperature resistance compared to aluminum foil, withstanding temperatures up to 150degC (302degF) without degradation, while aluminum foil can tolerate higher temperatures but may oxidize or become brittle over time. In terms of thermal performance, Mylar's reflective surface provides excellent insulation by reflecting up to 97% of radiant heat, making it ideal for thermal blankets and insulation applications, whereas aluminum foil's heat conduction can lead to quicker heat transfer. This makes Mylar more effective for maintaining temperature stability in low to moderate heat environments.

Weight and Flexibility Analysis

Mylar weighs significantly less than aluminum foil, providing an advantage in applications where minimizing weight is critical, such as in aerospace and packaging industries. Its high tensile strength and flexibility allow Mylar to endure multiple bends and folds without tearing, unlike the more brittle aluminum foil which tends to crack under repeated stress. These properties make Mylar a preferred material for lightweight, durable insulation and reflective surfaces.

Common Applications: Mylar vs Aluminum Foil

Mylar excels in insulation and packaging, often used in emergency blankets and food wraps due to its reflective and durable properties. Aluminum foil is preferred for cooking, food storage, and insulation in HVAC systems because of its heat resistance and malleability. Both materials serve in insulation, but Mylar's lightweight and moisture resistance make it ideal for survival gear, while aluminum foil offers superior heat conductivity for kitchen and industrial applications.

Environmental Impact and Recyclability

Mylar, a polyester film made from polyethylene terephthalate (PET), offers a lower environmental impact than aluminum foil due to its lighter weight and greater energy efficiency during production. While aluminum foil is recyclable, the recycling process is energy-intensive and often contaminated by food residues, reducing its practical recyclability. Mylar's recyclability depends on local facilities accepting PET films, but its durability and reusability potential contribute to reduced waste compared to single-use aluminum foil.

Cost Considerations and Market Availability

Mylar typically costs more than aluminum foil due to its specialized polyester film composition and enhanced durability, impacting budget decisions for large-scale uses. Aluminum foil enjoys widespread market availability and lower price points, making it a preferred choice for everyday applications and cost-sensitive industries. The limited production of Mylar results in less flexible supply chains, affecting its accessibility in comparison to aluminum foil's extensive distribution network.

Choosing the Right Material for Your Needs

Mylar offers superior tensile strength and moisture resistance compared to aluminum foil, making it ideal for long-term insulation and packaging needs. Aluminum foil provides excellent heat conductivity and is more cost-effective for cooking and short-term food storage. Selecting between Mylar and aluminum foil depends on factors such as durability requirements, moisture barrier properties, and cost-efficiency for your specific application.

Mylar vs Aluminum Foil Infographic

materialdif.com

materialdif.com