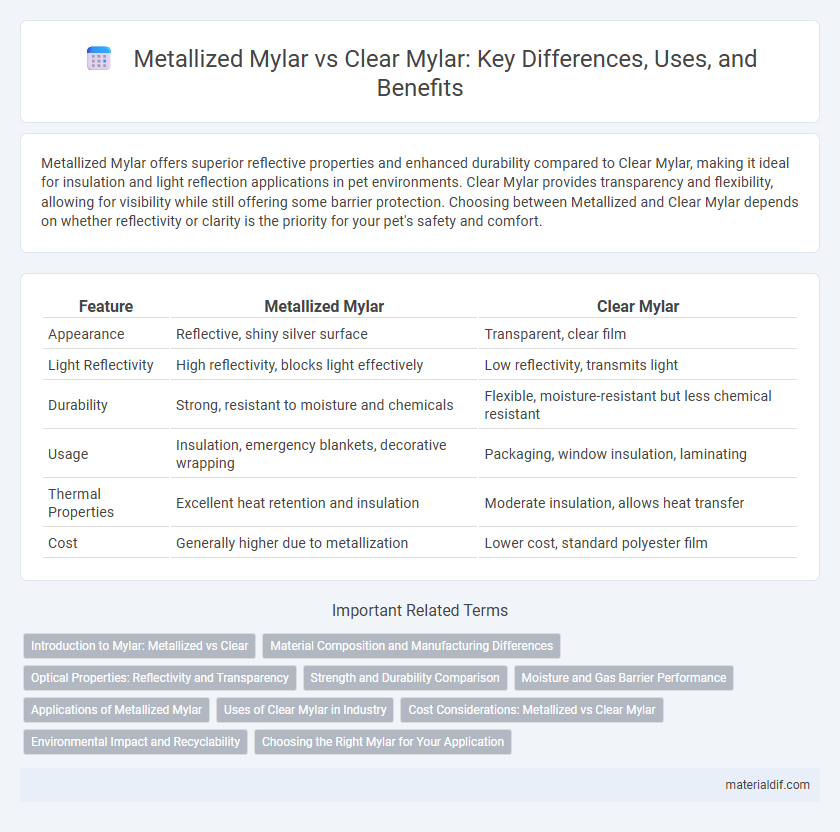

Metallized Mylar offers superior reflective properties and enhanced durability compared to Clear Mylar, making it ideal for insulation and light reflection applications in pet environments. Clear Mylar provides transparency and flexibility, allowing for visibility while still offering some barrier protection. Choosing between Metallized and Clear Mylar depends on whether reflectivity or clarity is the priority for your pet's safety and comfort.

Table of Comparison

| Feature | Metallized Mylar | Clear Mylar |

|---|---|---|

| Appearance | Reflective, shiny silver surface | Transparent, clear film |

| Light Reflectivity | High reflectivity, blocks light effectively | Low reflectivity, transmits light |

| Durability | Strong, resistant to moisture and chemicals | Flexible, moisture-resistant but less chemical resistant |

| Usage | Insulation, emergency blankets, decorative wrapping | Packaging, window insulation, laminating |

| Thermal Properties | Excellent heat retention and insulation | Moderate insulation, allows heat transfer |

| Cost | Generally higher due to metallization | Lower cost, standard polyester film |

Introduction to Mylar: Metallized vs Clear

Metallized Mylar features a thin layer of metal, typically aluminum, laminated onto the plastic film, enhancing its reflective and barrier properties, making it ideal for insulation, packaging, and decorative purposes. Clear Mylar, a transparent polyester film, offers durability, chemical resistance, and moisture barrier without the reflective or insulating properties of metallized versions, suitable for applications requiring clarity and protection. Choosing between Metallized and Clear Mylar depends on the specific needs for reflectivity, light transmission, and barrier performance in various industrial and consumer uses.

Material Composition and Manufacturing Differences

Metallized Mylar consists of a polyethylene terephthalate (PET) film coated with a thin layer of metal, typically aluminum, applied through vacuum deposition, enhancing its reflective properties and durability. Clear Mylar is made from the same polyester film base but remains uncoated, preserving transparency and allowing light to pass through without reflection. The manufacturing process for Metallized Mylar involves an additional metallization step after film extrusion, while Clear Mylar undergoes only film extrusion and annealing, resulting in different optical and physical properties suited for specific applications.

Optical Properties: Reflectivity and Transparency

Metallized Mylar exhibits high reflectivity due to its thin metal coating, making it ideal for light reflection and insulation applications, while Clear Mylar offers superior transparency with minimal light distortion, suited for protective overlays and packaging. The reflective surface of Metallized Mylar enhances energy efficiency by reflecting infrared and UV rays, whereas Clear Mylar maintains visibility and clarity for displays and optical uses. These distinct optical properties determine their specific uses in industries such as electronics, solar energy, and packaging.

Strength and Durability Comparison

Metallized Mylar offers enhanced strength and durability due to its aluminum coating, which provides superior resistance to tears, punctures, and environmental factors compared to Clear Mylar. Clear Mylar, while flexible and transparent, lacks the reinforced metal layer, making it more susceptible to physical damage and less effective against moisture and UV exposure. For applications requiring robust protection and longevity, Metallized Mylar is the preferred choice over Clear Mylar.

Moisture and Gas Barrier Performance

Metallized Mylar offers superior moisture and gas barrier performance compared to Clear Mylar due to its thin metal coating, which significantly reduces permeability. This enhanced barrier property makes Metallized Mylar ideal for packaging sensitive products requiring extended shelf life and protection from oxidation and moisture ingress. Clear Mylar, while providing basic protection and clarity, has higher moisture vapor transmission rates, making it less effective in environments with high humidity or gas exposure.

Applications of Metallized Mylar

Metallized Mylar is widely used in insulation, packaging, and emergency blankets due to its excellent reflective properties and durability. It effectively reflects heat and light, making it ideal for thermal insulation in building materials and protective packaging for electronics. This material also finds applications in decorative and automotive industries for its metallic finish and enhanced barrier qualities.

Uses of Clear Mylar in Industry

Clear Mylar is extensively used in the electronics industry for insulating and protecting sensitive components due to its excellent dielectric properties and transparency. In packaging, Clear Mylar provides visibility of products while offering moisture and chemical resistance, making it ideal for food and pharmaceutical applications. It is also employed in the printing industry for overlays and laminates, ensuring durability and clarity in graphic displays.

Cost Considerations: Metallized vs Clear Mylar

Metallized Mylar typically costs more than Clear Mylar due to its enhanced reflective coating, which adds manufacturing complexity and material expenses. Clear Mylar offers a more budget-friendly option, suitable for applications where transparency or lower reflective properties are desired. Cost efficiency between the two depends on the specific use case, balancing material performance with price sensitivity.

Environmental Impact and Recyclability

Metallized Mylar, coated with a thin metal layer, poses more challenges for recycling due to its composite materials, often leading to contamination in recycling streams compared to Clear Mylar, which is easier to recycle as it consists primarily of a single polymer. The environmental impact of Metallized Mylar is higher because its production involves additional energy-intensive metal deposition processes and it tends to persist longer in landfills. Clear Mylar offers a more sustainable option by enabling more efficient recycling processes and reducing waste accumulation through improved material recovery.

Choosing the Right Mylar for Your Application

Metallized Mylar offers superior light reflection and moisture resistance, making it ideal for applications requiring enhanced insulation and durability, such as emergency blankets and grow room linings. Clear Mylar provides transparency and flexibility, suitable for packaging, protective coverings, and artwork preservation where visibility is crucial. Choosing the right Mylar depends on balancing opacity, reflective properties, and the specific environmental needs of your application.

Metallized Mylar vs Clear Mylar Infographic

materialdif.com

materialdif.com