Embossed Mylar offers enhanced durability and a textured surface that improves grip and reduces slippage, making it ideal for pet collars and accessories. Smooth Mylar provides a sleek, shiny finish that is easy to clean and visually appealing, perfect for decorative pet tags or lightweight applications. Choosing between embossed and smooth Mylar depends on whether functionality or aesthetics is the priority for your pet products.

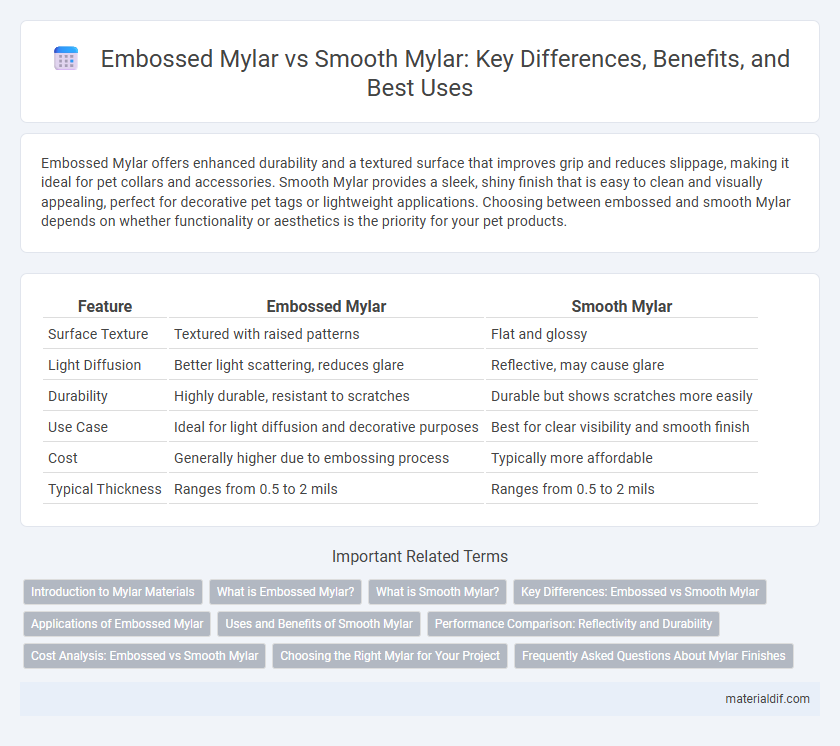

Table of Comparison

| Feature | Embossed Mylar | Smooth Mylar |

|---|---|---|

| Surface Texture | Textured with raised patterns | Flat and glossy |

| Light Diffusion | Better light scattering, reduces glare | Reflective, may cause glare |

| Durability | Highly durable, resistant to scratches | Durable but shows scratches more easily |

| Use Case | Ideal for light diffusion and decorative purposes | Best for clear visibility and smooth finish |

| Cost | Generally higher due to embossing process | Typically more affordable |

| Typical Thickness | Ranges from 0.5 to 2 mils | Ranges from 0.5 to 2 mils |

Introduction to Mylar Materials

Mylar materials consist of polyethylene terephthalate (PET) films known for their durability, clarity, and barrier properties. Embossed Mylar features a textured surface that enhances grip and reduces light reflection, making it ideal for packaging and decorative applications. Smooth Mylar offers a sleek, glossy finish with superior reflectivity and moisture resistance, commonly used in insulation and protective coverings.

What is Embossed Mylar?

Embossed Mylar features a textured surface created by pressing patterns or designs onto the film, enhancing grip and visual appeal compared to Smooth Mylar. This texture improves flexibility and durability, making it ideal for packaging, insulation, and decorative applications. The raised patterns on Embossed Mylar also reduce surface glare and increase heat resistance, distinguishing it from the flat, reflective surface of Smooth Mylar.

What is Smooth Mylar?

Smooth Mylar is a type of polyester film characterized by its glossy, flat surface without any texture or patterns, offering excellent clarity and reflectivity. It is commonly used in packaging, insulation, and protective coverings due to its durability, chemical resistance, and moisture barrier properties. Unlike embossed Mylar, which has raised patterns enhancing grip and diffusion, smooth Mylar provides a sleek finish ideal for applications requiring transparency and minimal surface interference.

Key Differences: Embossed vs Smooth Mylar

Embossed Mylar features a textured surface created by a patterned roller, enhancing grip, reducing glare, and improving durability, making it ideal for decorative packaging and protective coverings. Smooth Mylar offers a sleek, reflective surface with high clarity, optimal for applications requiring maximum visibility such as posters, photography backdrops, and insulation films. The primary differences lie in texture, visual effect, and functional usage, with embossed Mylar focusing on tactile and anti-slip properties, while smooth Mylar emphasizes clarity and reflectivity.

Applications of Embossed Mylar

Embossed Mylar is commonly used in applications requiring enhanced grip and tactile differentiation, such as packaging, labels, and decorative laminates, due to its textured surface that improves handling and aesthetic appeal. It also finds use in electronics and insulation industries where increased surface area can aid heat dissipation and adhesive bonding. The unique raised patterns of embossed Mylar contribute to its effectiveness in artistic projects and security printing, providing both functionality and visual distinction.

Uses and Benefits of Smooth Mylar

Smooth Mylar offers superior clarity and a consistent reflective surface ideal for applications requiring high visibility and precision, such as photography backdrops and protective screens. Its uniform texture enhances light diffusion and creates a sleek appearance, making it preferable for packaging, insulation, and printing industries. Smooth Mylar's durability and resistance to moisture and chemicals contribute to extended lifespan and reliable performance in various industrial and commercial uses.

Performance Comparison: Reflectivity and Durability

Embossed Mylar exhibits higher reflectivity by diffusing light more evenly, enhancing performance in applications like indoor gardening and photography. Smooth Mylar offers superior durability with a more resilient surface resistant to scratches and tears, making it ideal for long-term use. Choosing between embossed and smooth Mylar depends on balancing optimal light diffusion against mechanical strength requirements.

Cost Analysis: Embossed vs Smooth Mylar

Embossed Mylar typically incurs higher production costs due to the additional manufacturing processes required to create textured patterns, leading to increased labor and machinery expenses compared to Smooth Mylar. Smooth Mylar benefits from simpler production lines, resulting in lower material and operational costs, making it a more budget-friendly option for large-scale applications. When considering cost-effectiveness, Smooth Mylar presents significant savings, but Embossed Mylar's enhanced aesthetic and functional qualities may justify the premium in specialized uses.

Choosing the Right Mylar for Your Project

Embossed Mylar offers enhanced durability and reduced glare, making it ideal for applications requiring texture and visual interest, such as decorative packaging and arts and crafts projects. In contrast, Smooth Mylar provides a sleek, reflective surface suitable for high-quality printing and protective coverings where clarity and a clean finish are crucial. Selecting the right Mylar depends on balancing aesthetic needs with functional requirements like light diffusion, scratch resistance, and project environment.

Frequently Asked Questions About Mylar Finishes

Embossed Mylar features a textured surface that enhances grip and diffuses light, making it ideal for decorative packaging and specialty applications, while Smooth Mylar provides a sleek, reflective finish favored for clarity and barrier properties. Frequently asked questions about Mylar finishes often address durability differences, suitability for heat sealing, and aesthetic impact, with embossed finishes generally offering improved scratch resistance and smooth finishes preferred for crisp printing. Choosing between embossed and smooth Mylar depends on the specific requirements for visual effect, product protection, and handling in various industries.

Embossed Mylar vs Smooth Mylar Infographic

materialdif.com

materialdif.com