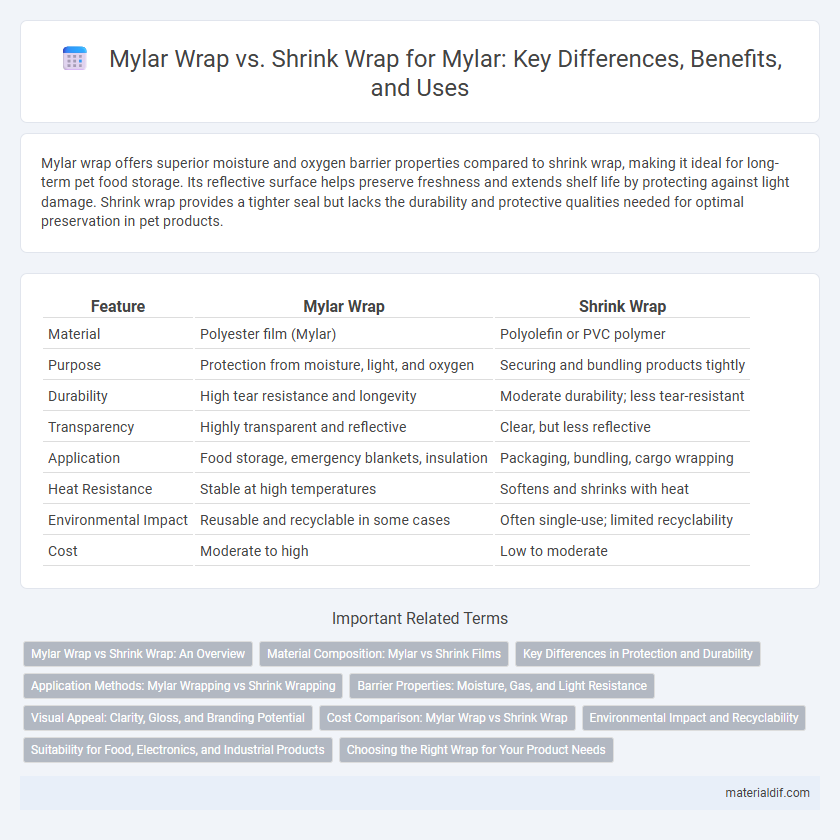

Mylar wrap offers superior moisture and oxygen barrier properties compared to shrink wrap, making it ideal for long-term pet food storage. Its reflective surface helps preserve freshness and extends shelf life by protecting against light damage. Shrink wrap provides a tighter seal but lacks the durability and protective qualities needed for optimal preservation in pet products.

Table of Comparison

| Feature | Mylar Wrap | Shrink Wrap |

|---|---|---|

| Material | Polyester film (Mylar) | Polyolefin or PVC polymer |

| Purpose | Protection from moisture, light, and oxygen | Securing and bundling products tightly |

| Durability | High tear resistance and longevity | Moderate durability; less tear-resistant |

| Transparency | Highly transparent and reflective | Clear, but less reflective |

| Application | Food storage, emergency blankets, insulation | Packaging, bundling, cargo wrapping |

| Heat Resistance | Stable at high temperatures | Softens and shrinks with heat |

| Environmental Impact | Reusable and recyclable in some cases | Often single-use; limited recyclability |

| Cost | Moderate to high | Low to moderate |

Mylar Wrap vs Shrink Wrap: An Overview

Mylar wrap offers superior durability and resistance to moisture and oxygen compared to shrink wrap, making it ideal for long-term preservation and packaging. Shrink wrap provides a tight seal by shrinking when heat is applied, which is effective for securing irregularly shaped items but less protective against air and moisture penetration. Both materials serve distinct purposes, with Mylar wrap excelling in barrier properties and shrink wrap excelling in conformity and cost-effectiveness.

Material Composition: Mylar vs Shrink Films

Mylar wrap is crafted from stretched polyethylene terephthalate (PET) film, known for its reflective, durable, and moisture-resistant properties that provide superior insulation and protection. Shrink wrap typically consists of polyolefin or PVC films that shrink tightly around objects when heat is applied, offering a flexible and conforming barrier but with less reflective strength compared to Mylar. The distinct material compositions influence their applications: Mylar excels in thermal insulation and static shielding, while shrink films prioritize secure, tight packaging and protection from dust and moisture.

Key Differences in Protection and Durability

Mylar wrap provides superior moisture and oxygen barrier properties compared to shrink wrap, making it ideal for long-term preservation and protection against environmental factors. Shrink wrap offers a tight, flexible seal that conforms closely to the product but lacks the same level of puncture resistance and thermal stability as Mylar. Durability-wise, Mylar withstands extreme temperatures and physical stress better, while shrink wrap is more vulnerable to tears and less effective in harsh conditions.

Application Methods: Mylar Wrapping vs Shrink Wrapping

Mylar wrap involves manually wrapping items with a highly reflective polyester film, creating a tight, protective seal without heat application, ideal for insulation and light-sensitive packaging. Shrink wrap employs heat to shrink polyolefin or PVC film tightly around products for secure containment and moisture resistance, commonly used in palletizing and product bundling. The key difference lies in Mylar's non-heat wrapping method providing durability and barrier properties, whereas shrink wrap relies on thermal contraction for a snug, tamper-evident fit.

Barrier Properties: Moisture, Gas, and Light Resistance

Mylar wrap offers superior barrier properties compared to shrink wrap, providing exceptional resistance to moisture, gases, and light, which helps preserve the freshness and integrity of packaged goods. Shrink wrap, while effective for protective sealing, generally allows higher permeability to moisture and gases, making it less ideal for long-term barrier protection. The metallized polyester structure of Mylar significantly reduces oxygen transmission rates and blocks ultraviolet light, enhancing product shelf life and quality retention.

Visual Appeal: Clarity, Gloss, and Branding Potential

Mylar wrap offers superior clarity and high-gloss finishes that enhance product visibility and appeal compared to shrink wrap, which often appears less transparent and matte. The reflective surface of Mylar creates an eye-catching display ideal for premium branding and detailed graphics. This elevated visual appeal supports stronger brand recognition and consumer engagement at the point of sale.

Cost Comparison: Mylar Wrap vs Shrink Wrap

Mylar wrap generally costs more upfront than shrink wrap due to its durable polyester film composition and reflective properties, making it ideal for long-term storage and insulation. Shrink wrap, made from polyolefin or PVC, is less expensive and suited for short-term packaging and bundling, but may require frequent replacement. When considering total cost over time, Mylar's reusability and protective qualities often result in lower expenses compared to the disposable nature of shrink wrap.

Environmental Impact and Recyclability

Mylar wrap, made from polyethylene terephthalate (PET), is highly recyclable and has a lower environmental footprint compared to shrink wrap, which is typically made from non-recyclable polyvinyl chloride (PVC) or low-density polyethylene (LDPE). Mylar's durability allows for multiple uses, reducing waste, whereas shrink wrap is often single-use and contributes significantly to plastic pollution. Recycling facilities widely accept Mylar films, promoting circular economy practices, while shrink wrap materials frequently end up in landfills or incinerators due to limited recyclability options.

Suitability for Food, Electronics, and Industrial Products

Mylar wrap offers excellent barrier properties and moisture resistance, making it highly suitable for food packaging where freshness and shelf life are critical. Shrink wrap provides a tight, conforming seal ideal for electronics, protecting devices from dust and static during shipping. For industrial products, Mylar wrap's durability and chemical resistance ensure robust protection against environmental factors, while shrink wrap is preferred for secure bundling and easy handling.

Choosing the Right Wrap for Your Product Needs

Mylar wrap offers superior durability, moisture resistance, and a glossy finish, making it ideal for long-term storage and protection of sensitive products such as electronics and food items. Shrink wrap provides a tight, form-fitting seal that is cost-effective and excellent for bundling multiple items or irregularly shaped products. Selecting the right wrap depends on product sensitivity, required shelf life, and packaging goals, with Mylar excelling in barrier properties and shrink wrap excelling in flexibility and affordability.

Mylar Wrap vs Shrink Wrap Infographic

materialdif.com

materialdif.com