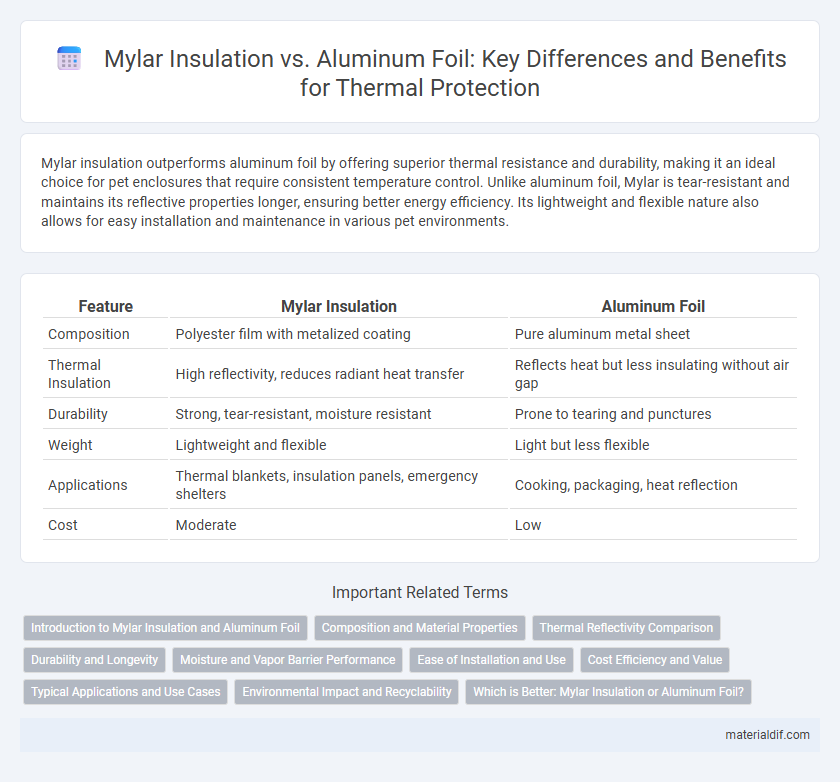

Mylar insulation outperforms aluminum foil by offering superior thermal resistance and durability, making it an ideal choice for pet enclosures that require consistent temperature control. Unlike aluminum foil, Mylar is tear-resistant and maintains its reflective properties longer, ensuring better energy efficiency. Its lightweight and flexible nature also allows for easy installation and maintenance in various pet environments.

Table of Comparison

| Feature | Mylar Insulation | Aluminum Foil |

|---|---|---|

| Composition | Polyester film with metalized coating | Pure aluminum metal sheet |

| Thermal Insulation | High reflectivity, reduces radiant heat transfer | Reflects heat but less insulating without air gap |

| Durability | Strong, tear-resistant, moisture resistant | Prone to tearing and punctures |

| Weight | Lightweight and flexible | Light but less flexible |

| Applications | Thermal blankets, insulation panels, emergency shelters | Cooking, packaging, heat reflection |

| Cost | Moderate | Low |

Introduction to Mylar Insulation and Aluminum Foil

Mylar insulation consists of a reflective polyester film designed to reduce radiant heat transfer, offering superior thermal performance compared to traditional aluminum foil. Aluminum foil, a thin sheet of metal, primarily serves as a heat and moisture barrier but lacks the multi-layer reflective properties of Mylar insulation. Both materials are widely used in thermal management applications, but Mylar insulation provides enhanced energy efficiency due to its layered reflective structure.

Composition and Material Properties

Mylar insulation is made from biaxially-oriented polyethylene terephthalate (BoPET), providing high tensile strength and excellent thermal resistance, whereas aluminum foil consists of pure aluminum, known for its superior reflectivity and conductivity. Mylar's polymer base offers flexibility and durability, resistant to tearing and moisture, while aluminum foil is more prone to punctures but provides effective radiation heat barrier properties. The distinct material compositions influence their suitability: Mylar excels in insulating applications requiring lightweight, strong, vapor-resistant layers, while aluminum foil is preferred where reflective heat shielding and conductivity are priorities.

Thermal Reflectivity Comparison

Mylar insulation offers superior thermal reflectivity compared to standard aluminum foil, reflecting up to 97% of radiant heat due to its metallized polyester film composition. Aluminum foil typically reflects around 88-92% of radiant heat but is less effective in reducing heat transfer through convection and conduction. The enhanced reflectivity of Mylar insulation makes it a preferred choice for energy-efficient insulation in buildings and thermal blankets.

Durability and Longevity

Mylar insulation offers superior durability compared to aluminum foil due to its multi-layer polymer composition that resists tearing and punctures. Unlike aluminum foil, which can degrade or corrode over time when exposed to moisture and physical stress, Mylar maintains its reflective properties and structural integrity for extended periods. This longevity makes Mylar insulation an ideal choice for long-term thermal management applications in both residential and industrial settings.

Moisture and Vapor Barrier Performance

Mylar insulation provides superior moisture and vapor barrier performance compared to standard aluminum foil due to its multi-layer polyester film structure that resists water vapor transmission effectively. Unlike aluminum foil, which can develop pinholes and degrade over time, Mylar maintains its integrity and reflective properties under varying environmental conditions. Enhanced durability and low permeability make Mylar insulation a preferred choice for long-lasting moisture control in building and packaging applications.

Ease of Installation and Use

Mylar insulation is lightweight and flexible, making it easier to cut and fit into irregular spaces compared to rigid aluminum foil. Its reflective surface remains effective without requiring precise application, simplifying the installation process. Aluminum foil, while durable, often needs extra adhesives or fasteners, increasing installation time and complexity.

Cost Efficiency and Value

Mylar insulation offers superior cost efficiency compared to aluminum foil due to its enhanced thermal resistance and durability, reducing energy expenses over time. While aluminum foil is initially cheaper, Mylar's long-term value is higher as it provides better reflective properties and moisture resistance, extending the lifespan of insulation systems. Choosing Mylar insulation maximizes energy savings and maintenance intervals, making it a more economically advantageous option for both residential and commercial applications.

Typical Applications and Use Cases

Mylar insulation is commonly used in building construction, automotive thermal barriers, and emergency blankets due to its excellent reflective properties and durability. Aluminum foil finds typical applications in food packaging, cooking, and HVAC duct insulation because of its flexibility and moisture resistance. Both materials serve as thermal barriers but Mylar insulation excels in scenarios requiring high tensile strength and long-term thermal performance.

Environmental Impact and Recyclability

Mylar insulation offers superior environmental benefits compared to traditional aluminum foil due to its reusable and long-lasting polyester film base, which reduces waste and energy consumption during production. Unlike aluminum foil, which is energy-intensive to produce and often not recycled properly due to contamination, Mylar can be recycled more efficiently when separated from other materials. The lower carbon footprint and enhanced recyclability of Mylar make it a sustainable choice for insulation applications.

Which is Better: Mylar Insulation or Aluminum Foil?

Mylar insulation offers superior thermal resistance due to its multi-layer reflective properties, making it more effective for heat retention and energy efficiency compared to standard aluminum foil. Aluminum foil primarily serves as a radiant heat barrier but lacks the insulating layers found in Mylar, resulting in less overall thermal performance. For applications requiring enhanced insulation and durability, Mylar insulation is the better choice over basic aluminum foil.

Mylar Insulation vs Aluminum Foil Infographic

materialdif.com

materialdif.com