Mylar coating provides enhanced durability and moisture resistance compared to metallized film, making it ideal for long-term pet product applications. Metallized film offers a shiny, reflective surface but is more prone to scratching and damage, reducing its effectiveness in protection. Choosing Mylar coating ensures a stronger barrier against environmental factors, improving the longevity of pet packaging and accessories.

Table of Comparison

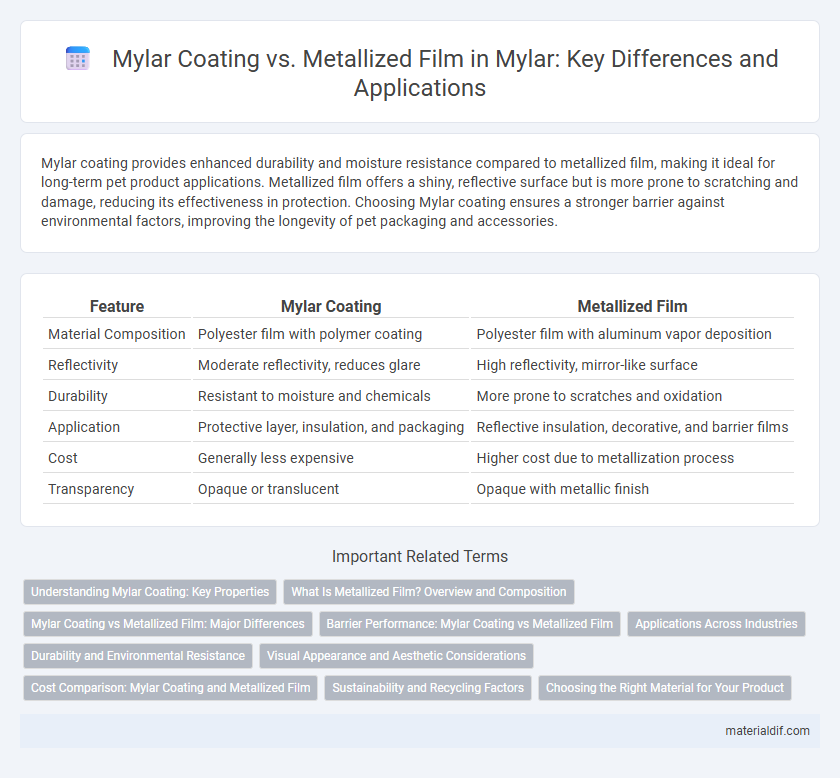

| Feature | Mylar Coating | Metallized Film |

|---|---|---|

| Material Composition | Polyester film with polymer coating | Polyester film with aluminum vapor deposition |

| Reflectivity | Moderate reflectivity, reduces glare | High reflectivity, mirror-like surface |

| Durability | Resistant to moisture and chemicals | More prone to scratches and oxidation |

| Application | Protective layer, insulation, and packaging | Reflective insulation, decorative, and barrier films |

| Cost | Generally less expensive | Higher cost due to metallization process |

| Transparency | Opaque or translucent | Opaque with metallic finish |

Understanding Mylar Coating: Key Properties

Mylar coating offers enhanced durability, superior moisture resistance, and excellent electrical insulation compared to standard metallized film. Its polymer-based composition provides flexibility and a smoother surface, making it ideal for high-performance applications such as packaging and electronic insulation. Understanding these key properties highlights Mylar coating's role in extending product lifespan and improving reliability under various environmental conditions.

What Is Metallized Film? Overview and Composition

Metallized film is a plastic film coated with a thin layer of metal, typically aluminum, to enhance its barrier properties, reflectivity, and durability. Unlike Mylar coating, which involves a polyester base with specific coatings for insulation or protection, metallized films combine substrate flexibility with metal's aesthetic and functional benefits. Commonly used in packaging, insulation, and decorative applications, metallized films provide moisture resistance and improved mechanical strength.

Mylar Coating vs Metallized Film: Major Differences

Mylar coating provides a durable, clear protective layer that enhances flexibility and resistance to moisture and chemicals, whereas metallized film involves depositing a thin layer of metal, typically aluminum, onto the Mylar surface to improve reflectivity and barrier properties. Mylar coating maintains transparency and is often used for insulation and packaging, while metallized film offers superior light and oxygen barrier capabilities, ideal for food packaging or insulation with reflective needs. The choice between Mylar coating and metallized film depends on the required balance between clarity, barrier performance, and application-specific durability.

Barrier Performance: Mylar Coating vs Metallized Film

Mylar coating offers superior moisture and oxygen barrier performance compared to standard metallized films, providing enhanced protection for sensitive products. The polymeric layers in Mylar coatings prevent permeation more effectively than the thin metallic layer in metallized films, which can develop pinholes and degrade over time. This makes Mylar coatings ideal for applications requiring long-term preservation and durability under varying environmental conditions.

Applications Across Industries

Mylar coating offers superior insulation and chemical resistance, making it ideal for electrical insulation, flexible packaging, and protective overlays in the electronics and automotive industries. Metallized film features a thin layer of metal vapor-deposited on the Mylar substrate, enhancing barrier properties against moisture, oxygen, and light, which is essential for food packaging, pharmaceuticals, and insulation in aerospace. Both materials provide tailored solutions, with Mylar coating excelling in durability and metallized film optimizing barrier performance across diverse industrial applications.

Durability and Environmental Resistance

Mylar coating offers superior durability and enhanced resistance to moisture, chemicals, and UV exposure compared to metallized film, making it ideal for long-term applications. Metallized films provide excellent barrier properties but are more susceptible to scratches, corrosion, and degradation under harsh environmental conditions. Choosing Mylar coating ensures improved longevity and reliable performance in demanding environments.

Visual Appearance and Aesthetic Considerations

Mylar coating provides a smooth, glossy finish that enhances color vibrancy and clarity, making it ideal for high-quality print applications requiring vivid visuals. Metallized film offers a reflective, metallic sheen that creates a striking, mirror-like appearance, often used for premium packaging and decorative purposes. The choice between Mylar coating and metallized film depends on whether a sleek, polished look or a shiny, eye-catching metallic effect is desired for the final presentation.

Cost Comparison: Mylar Coating and Metallized Film

Mylar coating generally incurs higher production costs compared to metallized film due to the complex layering and application processes involved in adding protective or functional coatings. Metallized film, produced by vacuum-depositing a thin layer of metal such as aluminum onto the polyester base, offers a cost-effective solution with reduced material and manufacturing expenses. When evaluating cost efficiency for large-scale applications, metallized film presents a budget-friendly alternative, while Mylar coating delivers enhanced durability and specific performance benefits at a premium.

Sustainability and Recycling Factors

Mylar coating enhances durability and moisture resistance while maintaining recyclability, making it a sustainable choice over metallized film, which involves aluminum vapor deposition that complicates recycling due to metal contamination. The absence of metal layers in Mylar coated films ensures easier separation and processing in recycling facilities, reducing environmental impact. Manufacturers increasingly prefer Mylar coatings for packaging and insulation applications to meet stricter sustainability regulations and circular economy goals.

Choosing the Right Material for Your Product

Mylar coating offers enhanced durability and resistance to moisture and chemicals, making it ideal for products requiring high-performance protective layers. Metallized film, with its reflective surface and excellent barrier properties, is preferred for applications needing light and oxygen resistance, such as food packaging and insulation. Selecting the right material depends on your product's specific requirements for flexibility, protection, and visual appeal.

Mylar Coating vs Metallized Film Infographic

materialdif.com

materialdif.com