Mylar printing offers superior durability and vibrant color retention compared to flexo printing, making it ideal for high-quality packaging applications. Unlike flexo printing, which is cost-effective for large runs but can result in less sharp images, Mylar printing ensures precise, glossy finishes that enhance brand visibility. This difference in print technology significantly impacts product presentation, with Mylar providing a premium look and flexo favoring efficiency and speed.

Table of Comparison

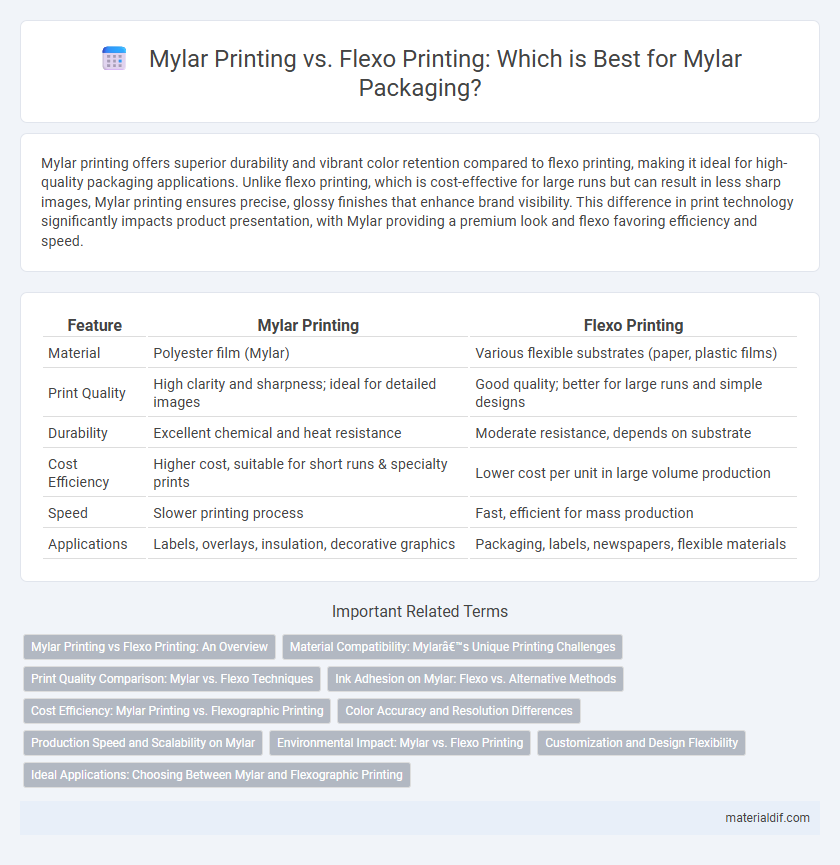

| Feature | Mylar Printing | Flexo Printing |

|---|---|---|

| Material | Polyester film (Mylar) | Various flexible substrates (paper, plastic films) |

| Print Quality | High clarity and sharpness; ideal for detailed images | Good quality; better for large runs and simple designs |

| Durability | Excellent chemical and heat resistance | Moderate resistance, depends on substrate |

| Cost Efficiency | Higher cost, suitable for short runs & specialty prints | Lower cost per unit in large volume production |

| Speed | Slower printing process | Fast, efficient for mass production |

| Applications | Labels, overlays, insulation, decorative graphics | Packaging, labels, newspapers, flexible materials |

Mylar Printing vs Flexo Printing: An Overview

Mylar printing offers superior clarity and durability for high-quality packaging and labels compared to flexo printing, which is favored for high-speed, cost-effective large-volume runs. Mylar printing excels in producing sharp, vibrant images on synthetic films, while flexo printing is versatile across various substrates but often compromises on image detail. Both methods serve distinct industrial needs, with Mylar printing preferred for premium applications requiring enhanced visual appeal and longevity.

Material Compatibility: Mylar’s Unique Printing Challenges

Mylar's polyester composition presents unique printing challenges compared to traditional flexo printing substrates, requiring inks with superior adhesion and flexibility to prevent cracking or peeling. Unlike flexo printing, which excels on porous surfaces like paper or cardboard, Mylar's non-porous, smooth surface demands specialized treatment or coatings to improve ink receptivity. Optimizing material compatibility involves selecting UV-curable or solvent-based inks designed specifically for polyester films to ensure durability and vibrant image quality on Mylar.

Print Quality Comparison: Mylar vs. Flexo Techniques

Mylar printing offers superior print quality with sharper image resolution and vibrant color reproduction compared to flexo printing, which can sometimes exhibit dot gain and lower detail precision. The smooth, non-porous surface of Mylar allows for consistent ink adhesion and crisp, clean lines ideal for high-definition graphics. Flexo printing is more cost-effective for large runs but may compromise fine detail clarity, making Mylar the preferred choice for premium packaging and labels requiring exceptional visual appeal.

Ink Adhesion on Mylar: Flexo vs. Alternative Methods

Ink adhesion on Mylar varies significantly between Flexo printing and alternative methods, influenced by ink formulation and surface treatment. Flexo printing typically requires specific solvent-based inks with high tack to ensure proper bonding on Mylar's smooth, non-porous surface, while digital and screen printing techniques use specialized UV or solvent inks that achieve superior adhesion. Proper surface corona or plasma treatment enhances ink receptivity across all methods, but Flexo remains cost-effective for large runs despite slightly lower adhesion durability compared to some alternative printing technologies.

Cost Efficiency: Mylar Printing vs. Flexographic Printing

Mylar printing offers cost efficiency through lower material waste and faster setup times compared to flexographic printing, making it ideal for short to medium production runs. Flexo printing requires higher initial plate costs and longer production runs to achieve cost-effectiveness, benefiting large-scale projects with consistent design requirements. Choosing between Mylar and flexo printing depends on balancing budget constraints with production volume and design complexity.

Color Accuracy and Resolution Differences

Mylar printing offers superior color accuracy due to its smooth polyester surface that allows precise ink adhesion and vibrant color reproduction. Flexo printing, although cost-effective for large runs, often results in lower resolution and less consistent color quality because of its use of flexible rubber plates and fast-drying inks. The higher resolution capabilities of Mylar printing make it ideal for detailed graphics and applications requiring sharp, consistent visuals.

Production Speed and Scalability on Mylar

Mylar printing offers rapid production speeds due to its compatibility with high-speed digital and screen printing technologies, enabling swift turnaround for large volumes. Flexo printing on Mylar is highly scalable, accommodating extensive print runs with consistent quality, making it ideal for mass production. Both methods leverage Mylar's smooth surface to enhance print clarity, but flexo excels in continuous, high-speed applications, while digital Mylar printing is preferred for shorter, adaptable runs.

Environmental Impact: Mylar vs. Flexo Printing

Mylar printing generally has a lower environmental impact compared to flexo printing due to its reduced use of inks and solvents, which result in fewer volatile organic compound (VOC) emissions. Flexo printing often involves higher energy consumption and waste generation because of its plate-making process and ink usage. Choosing Mylar printing supports sustainability by minimizing chemical waste and energy use.

Customization and Design Flexibility

Mylar printing offers superior customization and design flexibility compared to flexo printing, enabling intricate and vibrant designs with precise color matching. Its digital printing technology supports variable data and short runs, making it ideal for personalized packaging or limited editions. Flexo printing, while cost-effective for large volumes, lacks the fine detail and adaptability that Mylar printing provides for complex graphics and customized layouts.

Ideal Applications: Choosing Between Mylar and Flexographic Printing

Mylar printing excels in producing sharp, high-resolution images ideal for packaging that demands clarity and durability, particularly in food and pharmaceutical industries requiring moisture and chemical resistance. Flexographic printing is best suited for large-volume runs on flexible materials like plastic, foil, and paper, often used in labels, bags, and cartons due to its speed and cost-effectiveness. Selecting between Mylar and flexographic printing depends on the project's precision needs and material compatibility, with Mylar favored for premium, detailed prints and flexo chosen for economical, high-speed production.

Mylar Printing vs Flexo Printing Infographic

materialdif.com

materialdif.com