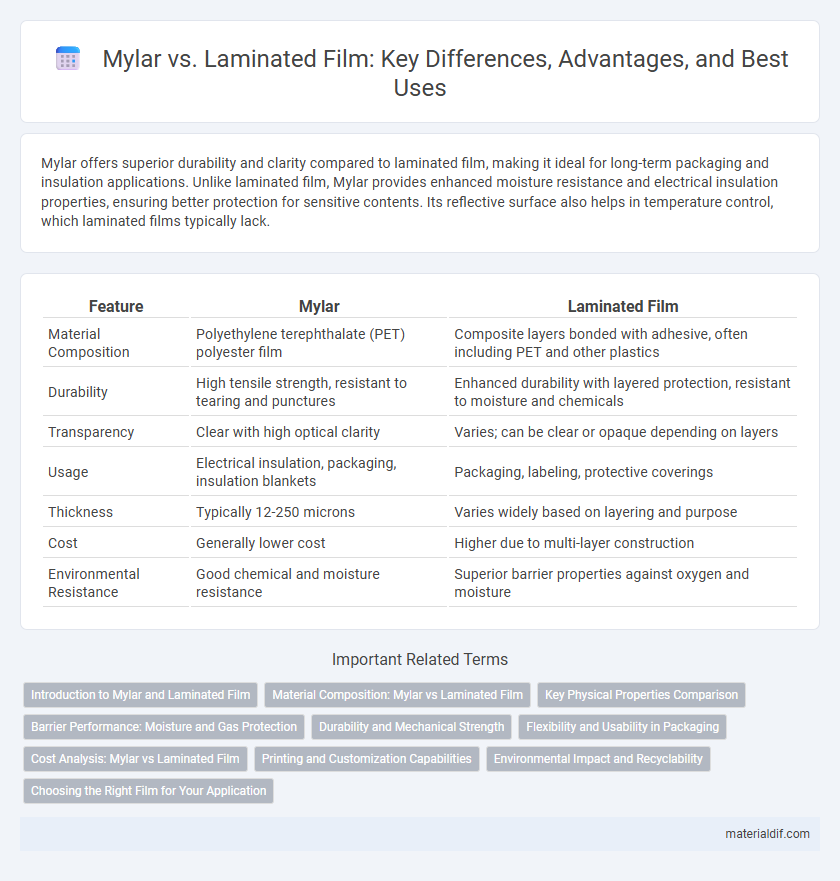

Mylar offers superior durability and clarity compared to laminated film, making it ideal for long-term packaging and insulation applications. Unlike laminated film, Mylar provides enhanced moisture resistance and electrical insulation properties, ensuring better protection for sensitive contents. Its reflective surface also helps in temperature control, which laminated films typically lack.

Table of Comparison

| Feature | Mylar | Laminated Film |

|---|---|---|

| Material Composition | Polyethylene terephthalate (PET) polyester film | Composite layers bonded with adhesive, often including PET and other plastics |

| Durability | High tensile strength, resistant to tearing and punctures | Enhanced durability with layered protection, resistant to moisture and chemicals |

| Transparency | Clear with high optical clarity | Varies; can be clear or opaque depending on layers |

| Usage | Electrical insulation, packaging, insulation blankets | Packaging, labeling, protective coverings |

| Thickness | Typically 12-250 microns | Varies widely based on layering and purpose |

| Cost | Generally lower cost | Higher due to multi-layer construction |

| Environmental Resistance | Good chemical and moisture resistance | Superior barrier properties against oxygen and moisture |

Introduction to Mylar and Laminated Film

Mylar is a type of polyester film known for its high tensile strength, chemical stability, and excellent barrier properties, commonly used in insulation, packaging, and electronics. Laminated film combines layers of different materials, including Mylar, to enhance durability, moisture resistance, and mechanical performance for applications in flexible packaging and industrial uses. The choice between Mylar and laminated film depends on specific requirements such as flexibility, protection level, and environmental resistance.

Material Composition: Mylar vs Laminated Film

Mylar is a polyester film made from stretched polyethylene terephthalate (PET), offering high tensile strength, chemical stability, and excellent clarity. Laminated film combines multiple layers of different materials such as polyethylene, polypropylene, or aluminum foil, bonded together to enhance barrier properties, durability, and flexibility. The single-material composition of Mylar contrasts with the multi-layer structure of laminated films, affecting their performance in applications like insulation, packaging, and electrical insulation.

Key Physical Properties Comparison

Mylar, a biaxially-oriented polyethylene terephthalate (BoPET) film, offers superior tensile strength and dimensional stability compared to laminated films, which typically combine multiple layers including plastic and adhesive materials. Its exceptional clarity, high tensile modulus, and resistance to moisture and chemicals make Mylar preferable for applications requiring durability and transparency. Laminated films often provide enhanced barrier properties but may lack the mechanical robustness and thermal stability inherent to Mylar films.

Barrier Performance: Moisture and Gas Protection

Mylar exhibits superior barrier performance against moisture and gases compared to standard laminated films, maintaining product integrity by reducing permeability rates significantly. The unique polyester composition of Mylar creates a denser molecular structure that effectively prevents oxygen and water vapor transmission. These properties make Mylar ideal for applications requiring long-term preservation and protection from environmental contaminants.

Durability and Mechanical Strength

Mylar, a type of polyester film, offers superior durability and mechanical strength compared to laminated films due to its high tensile strength and resistance to impact, puncturing, and tearing. It maintains structural integrity under extreme temperature fluctuations and chemical exposure, making it ideal for protective packaging and insulation applications. Laminated films, while providing multi-layered barrier properties, often lack the same level of mechanical resilience and long-term durability as Mylar.

Flexibility and Usability in Packaging

Mylar offers superior flexibility compared to laminated films, allowing it to conform more easily to various package shapes without cracking or breaking. This enhanced pliability improves usability in packaging applications requiring tight seals and intricate designs. Laminated films, while durable, often lack the same level of flexibility, limiting their effectiveness in packaging that demands frequent handling or bending.

Cost Analysis: Mylar vs Laminated Film

Mylar generally offers a lower cost per square foot compared to laminated film due to its simpler manufacturing process and widespread availability. Laminated film, while more expensive initially, provides enhanced durability and barrier properties that can reduce long-term replacement expenses. Evaluating total lifecycle costs including maintenance and performance requirements often reveals Mylar as the cost-effective choice for short-term applications, whereas laminated film is preferred for high-durability needs.

Printing and Customization Capabilities

Mylar offers superior printing clarity and durability compared to laminated film, supporting high-resolution graphics and vibrant color reproduction essential for branding and packaging. Its smooth surface enables precise ink adhesion, allowing detailed customization with various printing techniques such as screen printing, flexography, and digital printing. Laminated films often restrict design complexity due to limited print receptivity and layering, making Mylar the preferred choice for high-quality, customizable applications.

Environmental Impact and Recyclability

Mylar, a brand of biaxially-oriented polyethylene terephthalate (BoPET), is more environmentally friendly than traditional laminated films, which often combine multiple materials that hinder recycling efforts. Mylar's single-material composition enhances recyclability, reducing landfill waste and promoting sustainable disposal practices. Laminated films, typically composed of layers such as aluminum foil and plastic, pose significant challenges for recycling facilities due to their mixed-material nature, negatively impacting environmental sustainability.

Choosing the Right Film for Your Application

Mylar offers superior tensile strength and dimensional stability compared to standard laminated films, making it ideal for high-performance applications requiring durability and clarity. Laminated films provide enhanced moisture and chemical resistance, suited for packaging and protective layers where barrier properties are critical. Evaluating environmental exposure, mechanical stress, and optical requirements helps determine the optimal choice between Mylar and laminated film for your specific application.

Mylar vs Laminated Film Infographic

materialdif.com

materialdif.com