Mylar film offers superior durability and thermal resistance compared to polypropylene film, making it ideal for long-term packaging and insulation applications. Polypropylene film is more flexible and cost-effective, often preferred for lightweight wrapping and food packaging where moisture barrier properties are less critical. Choosing between Mylar and polypropylene depends on the specific requirements for strength, temperature tolerance, and budget in pet product packaging.

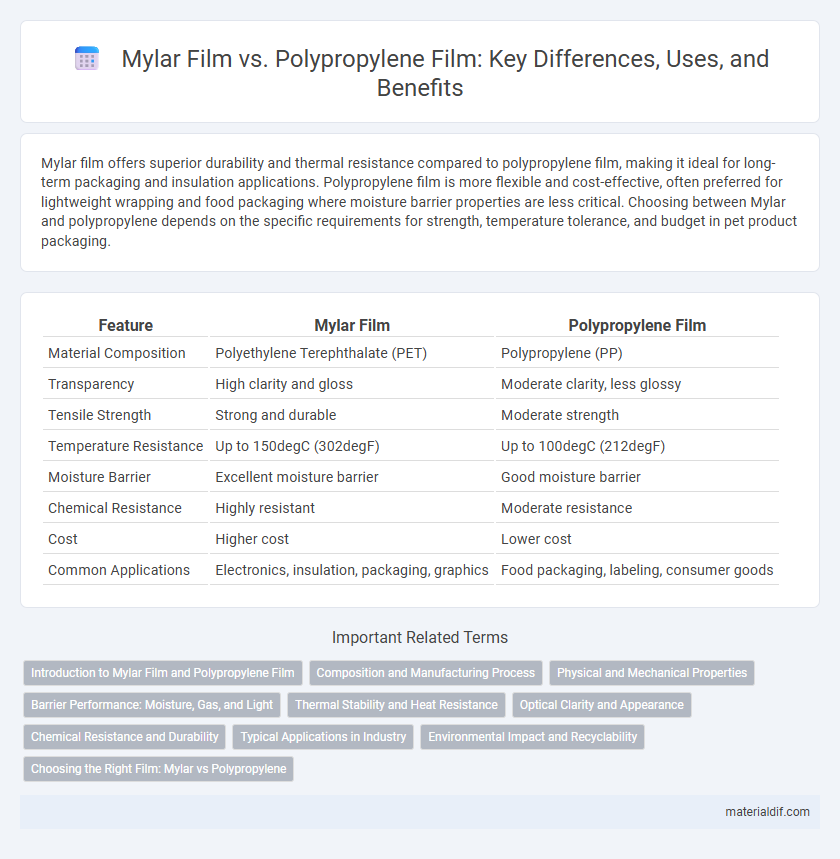

Table of Comparison

| Feature | Mylar Film | Polypropylene Film |

|---|---|---|

| Material Composition | Polyethylene Terephthalate (PET) | Polypropylene (PP) |

| Transparency | High clarity and gloss | Moderate clarity, less glossy |

| Tensile Strength | Strong and durable | Moderate strength |

| Temperature Resistance | Up to 150degC (302degF) | Up to 100degC (212degF) |

| Moisture Barrier | Excellent moisture barrier | Good moisture barrier |

| Chemical Resistance | Highly resistant | Moderate resistance |

| Cost | Higher cost | Lower cost |

| Common Applications | Electronics, insulation, packaging, graphics | Food packaging, labeling, consumer goods |

Introduction to Mylar Film and Polypropylene Film

Mylar film is a polyester film known for its high tensile strength, chemical stability, and excellent electrical insulation properties, commonly used in packaging, insulation, and electronics. Polypropylene film, on the other hand, offers superior moisture resistance, flexibility, and clarity, making it ideal for food packaging and labeling applications. Both films serve distinct functions driven by their physical and chemical characteristics, influencing their choice in industrial and consumer products.

Composition and Manufacturing Process

Mylar film is a biaxially-oriented polyethylene terephthalate (BoPET) known for its high tensile strength, thermal stability, and chemical resistance, produced through a stretching process that aligns polymer chains for enhanced durability. Polypropylene film, composed of isotactic polypropylene, is manufactured by extrusion or casting, resulting in a lighter, more flexible material with lower moisture absorption but less heat resistance compared to Mylar. The key difference lies in Mylar's polyester base and orienting method versus polypropylene's polyolefin base and simpler extrusion process, influencing their mechanical and barrier properties.

Physical and Mechanical Properties

Mylar film exhibits higher tensile strength and superior dimensional stability compared to polypropylene film, making it ideal for applications requiring durability and resistance to stretching. It also offers excellent thermal resistance and chemical stability, whereas polypropylene film provides greater flexibility and impact resistance at a lower cost. These physical and mechanical properties influence their respective uses in packaging, insulation, and electrical industries.

Barrier Performance: Moisture, Gas, and Light

Mylar film exhibits superior barrier performance against moisture, gases, and light compared to polypropylene film, making it ideal for sensitive packaging applications. Its polyester composition provides excellent resistance to water vapor transmission and oxygen permeation, ensuring product freshness and extended shelf life. In contrast, polypropylene film offers moderate moisture resistance but significantly lower gas and light barrier properties, limiting its effectiveness in protecting highly perishable goods.

Thermal Stability and Heat Resistance

Mylar film, a polyester film, exhibits superior thermal stability compared to polypropylene film, maintaining structural integrity at temperatures up to 150degC. Polypropylene film typically withstands heat up to 100-120degC but tends to deform or melt beyond this range. Mylar's enhanced heat resistance makes it ideal for applications requiring prolonged exposure to high temperatures without compromising durability.

Optical Clarity and Appearance

Mylar film offers superior optical clarity with a higher light transmission rate, resulting in a clearer, more transparent appearance compared to polypropylene film. It provides a smooth, glossy finish that enhances image sharpness and color vibrancy, making it ideal for applications requiring high visual quality. Polypropylene film, while more cost-effective, tends to have a slightly hazier look and less brilliance, impacting overall appearance in high-clarity uses.

Chemical Resistance and Durability

Mylar film offers superior chemical resistance compared to polypropylene film, making it ideal for applications involving exposure to solvents, oils, and acids. Its exceptional durability ensures prolonged performance under mechanical stress, heat, and UV exposure, exceeding the lifespan of polypropylene films. These properties make Mylar the preferred choice for industrial packaging and electrical insulation where chemical stability and long-term durability are critical.

Typical Applications in Industry

Mylar film, known for its exceptional tensile strength, chemical stability, and electrical insulation properties, is widely used in electronic components, solar panels, and flexible packaging. Polypropylene film, prized for its clarity, moisture resistance, and cost-effectiveness, is typically applied in food packaging, labeling, and medical packaging industries. Both films serve critical roles in packaging and industrial applications where durability and barrier properties are essential.

Environmental Impact and Recyclability

Mylar film, made from biaxially-oriented polyethylene terephthalate (BoPET), offers superior environmental benefits compared to polypropylene film due to its higher recyclability and longer lifecycle, resulting in reduced landfill waste. Polypropylene film, while lightweight and cost-effective, presents challenges in recycling due to contamination and limited acceptance in recycling facilities, leading to greater environmental strain. The durability and chemical stability of Mylar film enhance its reusability, positioning it as a more sustainable choice in packaging and industrial applications.

Choosing the Right Film: Mylar vs Polypropylene

Mylar film offers superior tensile strength, dimensional stability, and excellent barrier properties against moisture and gases compared to polypropylene film, making it ideal for applications requiring durability and protection. Polypropylene film provides better clarity, flexibility, and cost-effectiveness, suitable for packaging and labeling where transparency and affordability are key. Selecting between Mylar and polypropylene film depends on the application's need for strength, barrier performance, and budget constraints.

Mylar Film vs Polypropylene Film Infographic

materialdif.com

materialdif.com