Mylar tape offers superior heat resistance and dimensional stability compared to vinyl tape, making it ideal for electrical insulation and high-temperature applications. Vinyl tape provides better flexibility and adhesion on irregular surfaces, often preferred for general-purpose sealing and color-coding tasks. Choosing between Mylar and vinyl tape depends on the specific requirements for durability, temperature tolerance, and application environment.

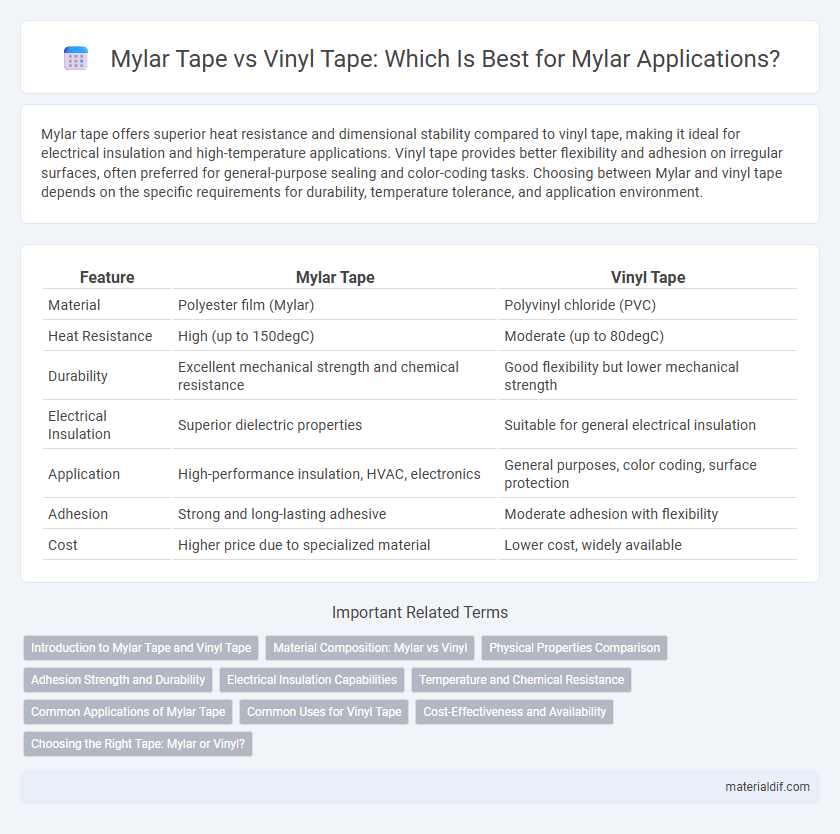

Table of Comparison

| Feature | Mylar Tape | Vinyl Tape |

|---|---|---|

| Material | Polyester film (Mylar) | Polyvinyl chloride (PVC) |

| Heat Resistance | High (up to 150degC) | Moderate (up to 80degC) |

| Durability | Excellent mechanical strength and chemical resistance | Good flexibility but lower mechanical strength |

| Electrical Insulation | Superior dielectric properties | Suitable for general electrical insulation |

| Application | High-performance insulation, HVAC, electronics | General purposes, color coding, surface protection |

| Adhesion | Strong and long-lasting adhesive | Moderate adhesion with flexibility |

| Cost | Higher price due to specialized material | Lower cost, widely available |

Introduction to Mylar Tape and Vinyl Tape

Mylar tape, made from polyethylene terephthalate film, offers high tensile strength, chemical resistance, and excellent thermal stability, making it ideal for electrical insulation and reflective applications. Vinyl tape, composed of polyvinyl chloride (PVC), provides flexibility, moisture resistance, and good abrasion protection, commonly used for color coding and general-purpose sealing. Both tapes differ significantly in properties and applications, with Mylar excelling in durability and heat resistance, while vinyl emphasizes flexibility and environmental sealing.

Material Composition: Mylar vs Vinyl

Mylar tape consists of biaxially-oriented polyethylene terephthalate (BoPET), which provides superior tensile strength, heat resistance, and dimensional stability compared to vinyl tape made from polyvinyl chloride (PVC). The polyester base of Mylar offers high dielectric strength and chemical resistance, making it ideal for electrical insulation and reflective applications. Vinyl tape's PVC composition is more flexible and moisture-resistant but lacks the thermal and mechanical durability that Mylar's synthetic polyester structure delivers.

Physical Properties Comparison

Mylar tape exhibits superior tensile strength and dimensional stability compared to vinyl tape, making it ideal for applications requiring durability under stress and high temperatures. Mylar's low moisture absorption contributes to better electrical insulation, while vinyl tape offers greater flexibility and conformability to irregular surfaces. The higher dielectric strength and resistance to chemical exposure make Mylar tape preferable for industrial and electrical uses, whereas vinyl tape suits temporary masking and surface protection.

Adhesion Strength and Durability

Mylar tape offers superior adhesion strength compared to vinyl tape, making it ideal for applications requiring long-lasting bonds on smooth or curved surfaces. Its durability exceeds that of vinyl tape, with high resistance to heat, moisture, and chemicals ensuring reliable performance in harsh environments. Vinyl tape, while flexible and less expensive, tends to lose adhesion over time and may degrade under prolonged exposure to heat and UV light.

Electrical Insulation Capabilities

Mylar tape exhibits superior electrical insulation capabilities due to its high dielectric strength, typically around 5000 volts per mil, making it ideal for protecting sensitive electrical components. Vinyl tape, while offering moderate insulation with dielectric strength near 1000 volts per mil, is more prone to degradation under heat and chemical exposure. Mylar's resistance to moisture, chemicals, and heat enhances its reliability for long-term electrical insulation compared to vinyl tape.

Temperature and Chemical Resistance

Mylar tape offers superior temperature resistance, typically withstanding continuous exposure up to 150degC or higher, compared to vinyl tape which usually tolerates temperatures only up to 80degC. In chemical resistance, Mylar tape excels against solvents, oils, and acids, maintaining adhesive integrity and durability under harsh conditions, whereas vinyl tape tends to degrade or lose adhesion when exposed to similar chemicals. This makes Mylar tape the preferred choice for applications requiring high thermal stability and chemical resilience.

Common Applications of Mylar Tape

Mylar tape is widely used in high-temperature electrical insulation, including motor winding, transformer, and coil wrap applications due to its excellent heat resistance and dielectric strength. It is also popular for reflective insulation in HVAC systems and protective shielding in aerospace and electronics industries. Vinyl tape, by contrast, is generally preferred for moisture sealing, color coding, and general-purpose surface protection tasks.

Common Uses for Vinyl Tape

Vinyl tape is commonly used for electrical insulation, color coding, and surface protection due to its flexibility and strong adhesive properties. It is preferred in automotive wiring, packaging, and general-purpose sealing applications where durability and moisture resistance are essential. Unlike Mylar tape, vinyl tape offers better conformability on irregular surfaces, making it ideal for temporary repairs and bundling cables.

Cost-Effectiveness and Availability

Mylar tape offers superior cost-effectiveness compared to vinyl tape due to its durability and resistance to heat and chemicals, reducing the need for frequent replacements. While vinyl tape is widely available and generally cheaper upfront, its shorter lifespan leads to higher long-term costs. Mylar tape's enhanced availability in industrial markets makes it the preferred choice for applications demanding reliability and value over time.

Choosing the Right Tape: Mylar or Vinyl?

Mylar tape offers superior heat resistance and electrical insulation, making it ideal for high-temperature environments and electronic applications, while vinyl tape excels in flexibility, moisture resistance, and ease of application for general-purpose sealing and surface protection. When choosing between Mylar and vinyl tape, consider the operating temperature, environmental exposure, and required durability to match the tape's material properties to your specific project needs. Mylar's tensile strength and chemical inertness provide long-term performance in demanding conditions where vinyl may degrade or lose adhesion.

Mylar Tape vs Vinyl Tape Infographic

materialdif.com

materialdif.com