Mylar film offers superior tensile strength and dimensional stability compared to nylon film, making it ideal for applications requiring durability and resistance to stretching. Unlike nylon, Mylar exhibits excellent electrical insulation properties and low moisture absorption, enhancing its performance in sensitive electronic components. While nylon provides better abrasion resistance and flexibility, Mylar's clarity and chemical inertness make it a preferred choice in packaging and insulation industries.

Table of Comparison

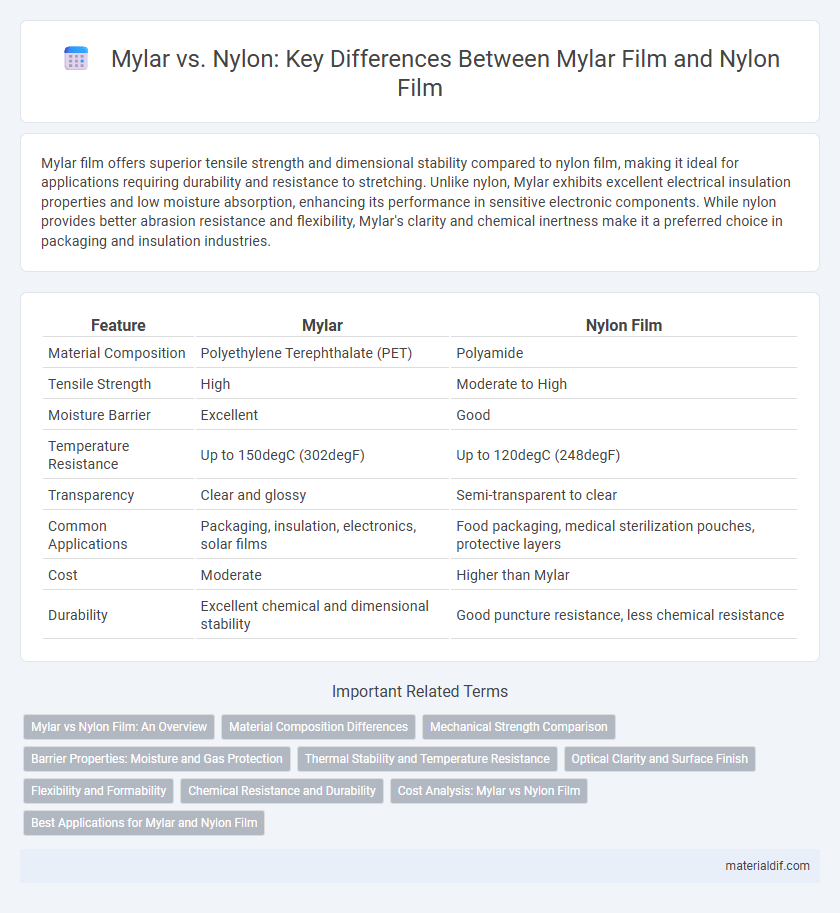

| Feature | Mylar | Nylon Film |

|---|---|---|

| Material Composition | Polyethylene Terephthalate (PET) | Polyamide |

| Tensile Strength | High | Moderate to High |

| Moisture Barrier | Excellent | Good |

| Temperature Resistance | Up to 150degC (302degF) | Up to 120degC (248degF) |

| Transparency | Clear and glossy | Semi-transparent to clear |

| Common Applications | Packaging, insulation, electronics, solar films | Food packaging, medical sterilization pouches, protective layers |

| Cost | Moderate | Higher than Mylar |

| Durability | Excellent chemical and dimensional stability | Good puncture resistance, less chemical resistance |

Mylar vs Nylon Film: An Overview

Mylar, a type of polyester film, offers superior dimensional stability and chemical resistance compared to nylon film, making it ideal for applications requiring durability under stress. Nylon film exhibits excellent flexibility and abrasion resistance but is more prone to moisture absorption, which can affect performance in humid environments. Mylar's superior electrical insulation properties and resistance to heat also distinguish it as a preferred material in electronics and industrial uses.

Material Composition Differences

Mylar is a polyester film made from stretched polyethylene terephthalate (PET), offering high tensile strength, chemical stability, and excellent dimensional stability. Nylon film, composed of polyamide, provides superior puncture resistance and flexibility but has higher moisture absorption compared to Mylar. The distinct molecular structures in Mylar and Nylon influence their barrier properties, mechanical strength, and applications in packaging, insulation, and industrial uses.

Mechanical Strength Comparison

Mylar exhibits superior mechanical strength compared to nylon film, featuring higher tensile strength and greater resistance to stretching and tearing, making it ideal for applications requiring durability. Mylar's enhanced dimensional stability under mechanical stress outperforms nylon, which tends to deform more easily under load due to its lower modulus of elasticity. These properties position Mylar as the preferred choice in industries such as packaging, insulation, and electronics, where mechanical robustness is critical.

Barrier Properties: Moisture and Gas Protection

Mylar offers superior barrier properties compared to nylon film, providing enhanced moisture and gas protection due to its polyethylene terephthalate (PET) composition. Mylar's dense molecular structure significantly reduces permeability, making it ideal for applications requiring high resistance to oxygen and water vapor transmission. In contrast, nylon films exhibit greater moisture permeability, making Mylar the preferred choice for long-term preservation and packaging solutions.

Thermal Stability and Temperature Resistance

Mylar exhibits superior thermal stability compared to nylon film, maintaining its structural integrity at temperatures up to 150degC, whereas nylon typically begins to deform around 120degC. The higher melting point and consistent dimensional stability of Mylar make it ideal for applications requiring prolonged exposure to heat. Nylon film tends to absorb moisture, which can further reduce its temperature resistance and mechanical properties under thermal stress.

Optical Clarity and Surface Finish

Mylar offers superior optical clarity compared to nylon film, featuring a high-gloss surface that enhances light transmission and image sharpness. Nylon film tends to have a matte or semi-gloss finish, which diffuses light and reduces transparency, making it less ideal for applications requiring clear visibility or vibrant colors. The smooth surface finish of Mylar also provides better resistance to scratches and environmental wear, ensuring consistent visual performance over time.

Flexibility and Formability

Mylar film exhibits superior flexibility and formability compared to nylon film, making it ideal for applications requiring precise shaping and durability. Its polyester composition allows Mylar to withstand repeated bending without cracking, unlike nylon, which tends to have lower elasticity and may deform under stress. This enhanced flexibility makes Mylar a preferred choice in flexible packaging, insulating layers, and protective covers where consistent form retention is critical.

Chemical Resistance and Durability

Mylar exhibits superior chemical resistance compared to nylon film, effectively withstanding exposure to acids, alkalis, and solvents without degradation. Its polyester composition contributes to high tensile strength and durability, making it ideal for applications requiring long-term stability. In contrast, nylon film tends to absorb moisture, which can reduce its mechanical properties and chemical resistance over time.

Cost Analysis: Mylar vs Nylon Film

Mylar film generally offers a lower cost per square foot compared to nylon film, making it a more budget-friendly option for applications requiring durability and moisture resistance. Nylon film tends to be more expensive due to its superior strength and flexibility, which contribute to longer lifespan in demanding environments. When evaluating cost analysis, Mylar provides a cost-effective solution for projects with moderate performance requirements, while nylon film justifies its higher price in heavy-duty or high-stress applications.

Best Applications for Mylar and Nylon Film

Mylar, a polyester film known for its excellent tensile strength, chemical stability, and high temperature resistance, is best suited for electrical insulation, packaging, and reflective surfaces where durability and heat tolerance are critical. Nylon film offers superior puncture resistance, flexibility, and moisture barrier properties, making it ideal for food packaging, vacuum bags, and medical packaging applications. Selecting between Mylar and Nylon film depends on specific requirements such as strength, moisture resistance, and thermal stability for optimal performance.

Mylar vs Nylon Film Infographic

materialdif.com

materialdif.com