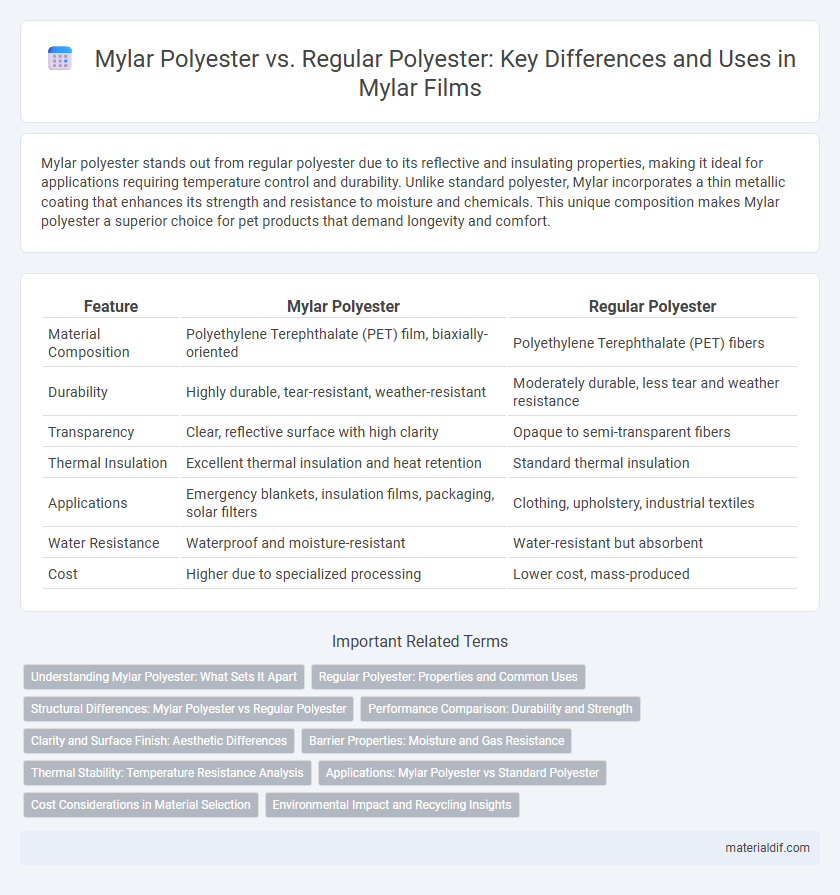

Mylar polyester stands out from regular polyester due to its reflective and insulating properties, making it ideal for applications requiring temperature control and durability. Unlike standard polyester, Mylar incorporates a thin metallic coating that enhances its strength and resistance to moisture and chemicals. This unique composition makes Mylar polyester a superior choice for pet products that demand longevity and comfort.

Table of Comparison

| Feature | Mylar Polyester | Regular Polyester |

|---|---|---|

| Material Composition | Polyethylene Terephthalate (PET) film, biaxially-oriented | Polyethylene Terephthalate (PET) fibers |

| Durability | Highly durable, tear-resistant, weather-resistant | Moderately durable, less tear and weather resistance |

| Transparency | Clear, reflective surface with high clarity | Opaque to semi-transparent fibers |

| Thermal Insulation | Excellent thermal insulation and heat retention | Standard thermal insulation |

| Applications | Emergency blankets, insulation films, packaging, solar filters | Clothing, upholstery, industrial textiles |

| Water Resistance | Waterproof and moisture-resistant | Water-resistant but absorbent |

| Cost | Higher due to specialized processing | Lower cost, mass-produced |

Understanding Mylar Polyester: What Sets It Apart

Mylar polyester is a specialized form of polyester film known for its exceptional tensile strength, chemical resistance, and thermal stability compared to regular polyester fibers. Unlike standard polyester fabrics used in textiles, Mylar is a biaxially-oriented polyethylene terephthalate (BoPET) film that offers superior clarity, dimensional stability, and barrier properties, making it ideal for packaging, insulation, and electronic applications. Its unique manufacturing process and enhanced durability set Mylar apart by delivering performance characteristics that regular polyester cannot match.

Regular Polyester: Properties and Common Uses

Regular polyester is a synthetic fiber known for its durability, resistance to shrinking and stretching, and quick-drying properties. Its versatility makes it widely used in textiles, clothing, upholstery, ropes, and industrial applications. The material's affordability and strength contribute to its popularity in everyday products such as sportswear, home furnishings, and bags.

Structural Differences: Mylar Polyester vs Regular Polyester

Mylar polyester features a biaxially-oriented polyethylene terephthalate (PET) film structure that enhances its tensile strength, dimensional stability, and resistance to moisture compared to regular polyester fibers, which are typically spun and woven. The molecular orientation in Mylar is precisely controlled during manufacturing, resulting in an ultra-smooth surface and superior barrier properties, while regular polyester exhibits a more amorphous, fiber-based structure with less uniformity. These structural differences give Mylar polyester its distinct advantages in applications requiring high strength, flexibility, and clarity over conventional polyester materials.

Performance Comparison: Durability and Strength

Mylar polyester offers superior durability and strength compared to regular polyester due to its biaxially-oriented polyethylene terephthalate (BoPET) structure, which enhances tensile strength and resistance to stretching and shrinking. This results in higher puncture resistance and improved longevity in demanding applications such as insulation, packaging, and electrical insulation films. Regular polyester, while durable, typically exhibits lower tensile strength and is more susceptible to deformation under stress compared to Mylar's reinforced molecular alignment.

Clarity and Surface Finish: Aesthetic Differences

Mylar polyester exhibits superior clarity and a more reflective surface finish compared to regular polyester, making it ideal for applications requiring high optical transparency and a glossy appearance. The smooth, mirror-like texture of Mylar contributes to enhanced aesthetic appeal in packaging, labels, and protective films. Regular polyester typically has a more matte finish and reduced clarity, resulting in less vibrant and less visually striking products.

Barrier Properties: Moisture and Gas Resistance

Mylar polyester exhibits superior barrier properties compared to regular polyester, offering enhanced moisture and gas resistance due to its biaxially-oriented polyethylene terephthalate (BoPET) structure. This tightly oriented film significantly reduces permeability, making it ideal for applications requiring long-lasting protection against oxygen and water vapor. Regular polyester lacks this orientation, resulting in higher moisture absorption and gas transmission rates, which limits its effectiveness in barrier-intensive uses.

Thermal Stability: Temperature Resistance Analysis

Mylar polyester exhibits superior thermal stability compared to regular polyester, maintaining structural integrity at temperatures up to 150degC, while standard polyester typically withstands heat only up to 120degC. This enhanced temperature resistance makes Mylar ideal for applications requiring prolonged exposure to high heat without degradation. Its ability to resist thermal deformation ensures reliability in electronic insulation, packaging, and industrial uses where consistent performance under heat is critical.

Applications: Mylar Polyester vs Standard Polyester

Mylar polyester is widely used in insulation, packaging, and protective coatings due to its superior tensile strength, chemical resistance, and dimensional stability compared to regular polyester. Standard polyester finds applications in textiles, automotive parts, and everyday packaging where flexibility and cost-efficiency are prioritized over high performance. Mylar's unique barrier properties make it ideal for specialized uses like reflective surfaces and durable electrical insulation, distinguishing it from conventional polyester fibers in general manufacturing.

Cost Considerations in Material Selection

Mylar polyester typically incurs higher initial costs compared to regular polyester due to its enhanced durability, clarity, and resistance to moisture and gases, making it ideal for premium packaging and insulation applications. Regular polyester offers a cost-effective solution for general use, balancing performance with affordability for everyday textiles and manufacturing needs. Evaluating the long-term benefits of Mylar's superior strength and barrier properties against upfront expenses is critical in selecting the appropriate polyester material.

Environmental Impact and Recycling Insights

Mylar polyester, a biaxially-oriented polyethylene terephthalate (BoPET), offers superior durability and recyclability compared to regular polyester, which is primarily used in fiber form. Mylar's enhanced barrier properties reduce environmental waste by extending the life of packaged goods and enabling easier recycling processes, as it can be efficiently recovered through melt recycling systems. Regular polyester fibers often face challenges in recycling due to mixed material contamination and lower thermal stability, resulting in higher environmental burdens and limited circular economy applications.

Mylar Polyester vs Regular Polyester Infographic

materialdif.com

materialdif.com