Mylar is a brand name for biaxially-oriented polyethylene terephthalate (BoPET), known for its exceptional tensile strength, chemical stability, and reflective properties, making it ideal for insulation and packaging applications. PET, in its regular form, is widely used in beverage containers and food packaging due to its excellent durability, clarity, and recyclability but lacks Mylar's enhanced barrier and reflective qualities. Choosing between Mylar and standard PET depends on the specific requirements for strength, barrier protection, and thermal insulation in the intended application.

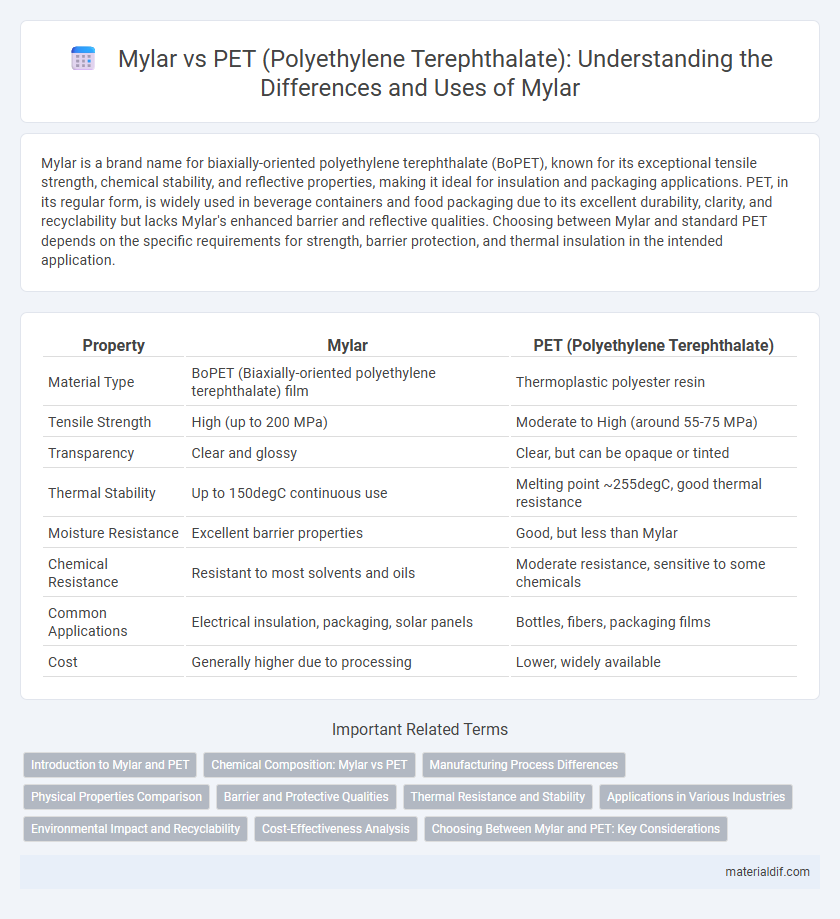

Table of Comparison

| Property | Mylar | PET (Polyethylene Terephthalate) |

|---|---|---|

| Material Type | BoPET (Biaxially-oriented polyethylene terephthalate) film | Thermoplastic polyester resin |

| Tensile Strength | High (up to 200 MPa) | Moderate to High (around 55-75 MPa) |

| Transparency | Clear and glossy | Clear, but can be opaque or tinted |

| Thermal Stability | Up to 150degC continuous use | Melting point ~255degC, good thermal resistance |

| Moisture Resistance | Excellent barrier properties | Good, but less than Mylar |

| Chemical Resistance | Resistant to most solvents and oils | Moderate resistance, sensitive to some chemicals |

| Common Applications | Electrical insulation, packaging, solar panels | Bottles, fibers, packaging films |

| Cost | Generally higher due to processing | Lower, widely available |

Introduction to Mylar and PET

Mylar is a brand name for biaxially oriented polyethylene terephthalate (BoPET), known for its exceptional strength, chemical stability, and reflective properties. PET, or polyethylene terephthalate, is a versatile thermoplastic polymer widely used in packaging, textiles, and film applications due to its durability and clarity. While both share the same chemical base, Mylar undergoes a special orientation process that enhances its tensile strength and barrier capabilities compared to standard PET films.

Chemical Composition: Mylar vs PET

Mylar is a brand name for biaxially oriented PET film manufactured by DuPont Teijin Films, sharing the same chemical composition as PET, which is a polymer derived from terephthalic acid and ethylene glycol. The primary difference lies in Mylar's specific manufacturing process that enhances its tensile strength, durability, and clarity compared to standard PET film. Both materials are polyethylene terephthalate but Mylar is often favored for applications requiring superior mechanical and thermal properties.

Manufacturing Process Differences

Mylar and PET share a core composition of polyethylene terephthalate, but Mylar undergoes a unique biaxial orientation process during manufacturing, involving simultaneous stretching in both machine and transverse directions, which enhances its strength and dimensional stability. PET films typically experience uniaxial or varying orientation methods, leading to differences in mechanical properties and surface characteristics. This biaxial orientation in Mylar results in superior tensile strength, clarity, and barrier properties compared to standard PET films.

Physical Properties Comparison

Mylar, a brand name for biaxially-oriented polyethylene terephthalate (BoPET), and generic PET films share similar chemical composition but differ in manufacturing processes that affect physical properties. Mylar exhibits superior tensile strength, dimensional stability, and clarity compared to standard PET, making it ideal for applications requiring durability and optical clarity such as packaging and insulation. Its enhanced thermal resistance and moisture barrier properties outperform conventional PET, providing better performance in demanding environmental conditions.

Barrier and Protective Qualities

Mylar is a trademarked form of biaxially-oriented polyethylene terephthalate (BoPET) known for its superior barrier properties against oxygen, moisture, and light compared to standard PET films. Its enhanced protective qualities include high tensile strength, dimensional stability, and resistance to chemical and thermal degradation, making it ideal for food packaging, insulation, and electronics shielding. Mylar's multi-layer coatings significantly improve its barrier effectiveness beyond ordinary PET, ensuring extended product shelf life and increased durability.

Thermal Resistance and Stability

Mylar, a brand of biaxially oriented PET, exhibits enhanced thermal resistance and stability compared to standard PET films due to its stretched and heat-set manufacturing process. This treatment provides Mylar with a higher melting point around 260degC and improved dimensional stability at elevated temperatures, making it suitable for applications requiring reliable performance under heat. In contrast, untreated PET films often have lower thermal endurance and may deform or lose mechanical integrity at temperatures above 150degC.

Applications in Various Industries

Mylar, a brand of biaxially oriented polyethylene terephthalate (BoPET), exhibits superior tensile strength, chemical resistance, and thermal stability compared to standard PET sheets, making it ideal for high-performance applications in electronics, packaging, and solar panels. Its exceptional barrier properties enable food and pharmaceutical industries to utilize Mylar for preserving freshness and extending shelf life. In contrast, PET's flexibility and lower cost favor its widespread use in beverage bottles, textiles, and general packaging.

Environmental Impact and Recyclability

Mylar, a brand name for biaxially oriented polyethylene terephthalate (BoPET), shares a similar chemical composition with standard PET but differs in its manufacturing process and physical properties. Both materials are recyclable; however, Mylar's multi-layer coatings can complicate recycling streams compared to pure PET, which is widely accepted in curbside programs and has established recycling infrastructure. From an environmental perspective, PET generally has a lower ecological footprint due to its simpler recycling process and higher recycling rates, while Mylar's specialized uses often result in limited recyclability and increased waste disposal challenges.

Cost-Effectiveness Analysis

Mylar, a branded form of biaxially-oriented polyethylene terephthalate (BoPET), often presents higher upfront costs compared to standard PET films but offers superior durability and chemical resistance, enhancing long-term value. Standard PET films are generally more cost-effective for single-use or low-durability applications due to lower production expenses and widespread availability. When assessing cost-effectiveness, the choice hinges on the application's performance requirements, with Mylar providing better longevity and reliability that can reduce replacement frequency and maintenance costs.

Choosing Between Mylar and PET: Key Considerations

Mylar and PET share similar chemical compositions, but Mylar is a branded form of biaxially-oriented polyethylene terephthalate (BoPET) known for its superior tensile strength and thermal stability, making it ideal for insulation and packaging applications. PET films typically offer more versatility and cost-effectiveness in general packaging and manufacturing, while Mylar's enhanced barrier properties protect against moisture and gases more effectively. Selecting between Mylar and PET depends on specific requirements such as durability, clarity, barrier performance, and budget constraints.

Mylar vs PET (Polyethylene Terephthalate) Infographic

materialdif.com

materialdif.com