Mylar lamination provides a durable, clear protective layer that enhances resistance to moisture, scratches, and UV damage, making it ideal for long-lasting preservation. UV coating offers a glossy or matte finish with added protection against fading caused by sunlight but is less flexible and may crack over time. Choosing between Mylar lamination and UV coating depends on the desired balance of durability, appearance, and environmental exposure.

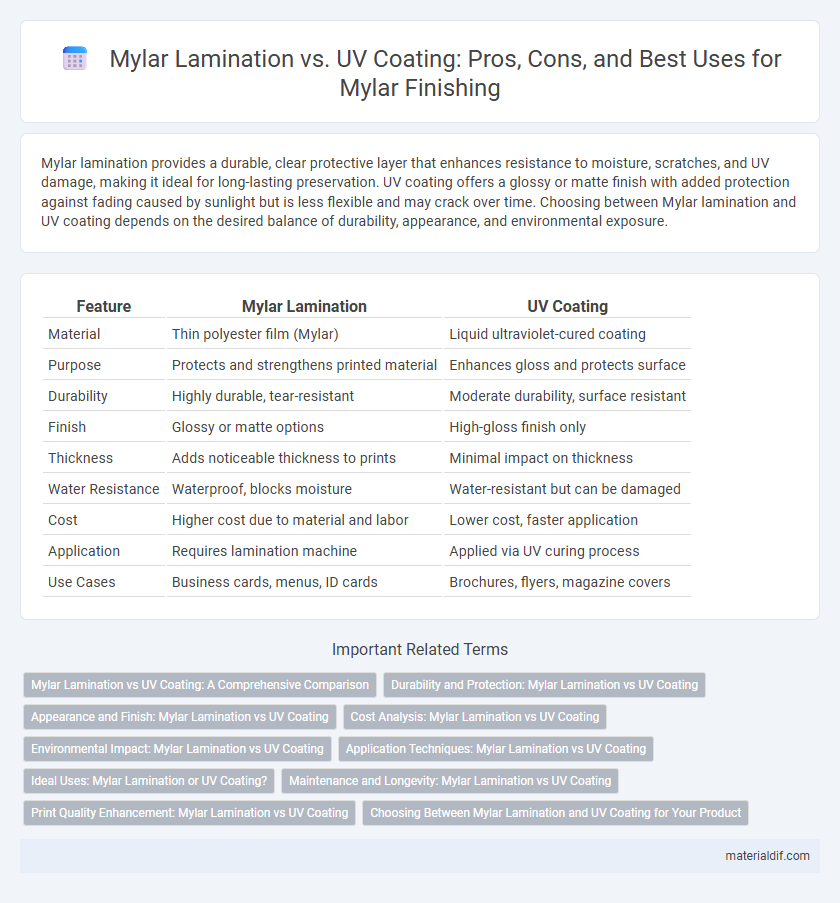

Table of Comparison

| Feature | Mylar Lamination | UV Coating |

|---|---|---|

| Material | Thin polyester film (Mylar) | Liquid ultraviolet-cured coating |

| Purpose | Protects and strengthens printed material | Enhances gloss and protects surface |

| Durability | Highly durable, tear-resistant | Moderate durability, surface resistant |

| Finish | Glossy or matte options | High-gloss finish only |

| Thickness | Adds noticeable thickness to prints | Minimal impact on thickness |

| Water Resistance | Waterproof, blocks moisture | Water-resistant but can be damaged |

| Cost | Higher cost due to material and labor | Lower cost, faster application |

| Application | Requires lamination machine | Applied via UV curing process |

| Use Cases | Business cards, menus, ID cards | Brochures, flyers, magazine covers |

Mylar Lamination vs UV Coating: A Comprehensive Comparison

Mylar lamination offers superior durability and moisture resistance by encapsulating prints in a clear polyester film, making it ideal for long-term protection and enhanced presentation. In contrast, UV coating provides a glossy, high-impact finish through a liquid polymer cured by ultraviolet light, enhancing color vibrancy but with less flexibility and abrasion resistance than Mylar. Choosing between Mylar lamination and UV coating depends on the desired balance of durability, aesthetic appeal, and handling conditions for printed materials.

Durability and Protection: Mylar Lamination vs UV Coating

Mylar lamination provides superior durability by creating a thick, flexible protective layer that resists tearing, moisture, and abrasion, making it ideal for long-lasting preservation. UV coating offers a glossy finish that enhances visual appeal and provides moderate scratch and fade resistance but is thinner and less robust compared to Mylar lamination. For optimal protection against environmental damage and handling wear, Mylar lamination delivers enhanced longevity and resilience over UV coating.

Appearance and Finish: Mylar Lamination vs UV Coating

Mylar lamination provides a smooth, glossy finish that enhances color vibrancy and offers durable protection against scratches and moisture, making it ideal for high-touch surfaces. UV coating delivers a high-shine, reflective appearance with a thicker, more rigid feel, accentuating printed details but is more prone to cracking under heavy folding. Both finishes elevate the visual impact, with Mylar lamination favored for flexibility and long-lasting clarity, while UV coating excels in brilliance and surface texture.

Cost Analysis: Mylar Lamination vs UV Coating

Mylar lamination typically incurs higher initial costs due to material and equipment expenses but offers superior durability and moisture resistance compared to UV coating, which is generally more cost-effective for short-term applications. UV coating requires less setup time and lower labor costs, making it a budget-friendly choice for high-volume projects with minimal exposure to wear and tear. Comparing cost efficiency, Mylar lamination provides better long-term value for items needing enhanced protection, while UV coating suits projects prioritizing lower upfront investment.

Environmental Impact: Mylar Lamination vs UV Coating

Mylar lamination uses polyethylene terephthalate (PET) film, which is recyclable and has a longer lifespan, reducing waste compared to UV coating that relies on chemical coatings with limited recyclability. UV coating involves volatile organic compounds (VOCs) and energy-intensive curing processes, contributing more to environmental pollution and carbon emissions than Mylar lamination. The durability of Mylar lamination offers extended product life, lowering the frequency of replacements and minimizing environmental impact over time.

Application Techniques: Mylar Lamination vs UV Coating

Mylar lamination involves applying a thin polyester film over printed materials, providing durable protection and enhanced gloss or matte finishes ideal for packaging and book covers. UV coating uses ultraviolet light to cure a liquid coating on surfaces, resulting in a high-gloss, scratch-resistant finish that is often used for business cards and postcards. The lamination process requires heat and pressure, while UV coating relies on rapid curing, making each technique suited to different production speeds and durability requirements.

Ideal Uses: Mylar Lamination or UV Coating?

Mylar lamination is ideal for documents requiring enhanced durability, water resistance, and long-term protection, such as ID cards, book covers, and archival materials. UV coating is best suited for surfaces needing high-gloss finishes and vibrant color enhancement, often used in promotional flyers, business cards, and packaging. Choosing between Mylar lamination and UV coating depends on whether durability and protection or aesthetic appeal and surface shine are the primary goals.

Maintenance and Longevity: Mylar Lamination vs UV Coating

Mylar lamination offers superior protection against scratches, moisture, and UV damage, significantly extending the lifespan of printed materials and reducing maintenance efforts. UV coating provides a glossy finish that enhances visual appeal but is more prone to chipping and wear over time, requiring more frequent touch-ups. The durability and resilience of Mylar lamination make it a preferred choice for applications demanding long-term preservation and minimal upkeep.

Print Quality Enhancement: Mylar Lamination vs UV Coating

Mylar lamination enhances print quality by providing a durable, glossy, or matte protective layer that resists scratches, moisture, and fading, ensuring long-lasting vibrancy of colors and sharpness of images. UV coating offers a high-gloss, reflective finish that intensifies color contrast and detail with rapid drying through ultraviolet light exposure but is more prone to scratches compared to Mylar lamination. Both methods improve print aesthetics; however, Mylar lamination excels in durability and protection, while UV coating focuses on enhancing visual impact and surface gloss.

Choosing Between Mylar Lamination and UV Coating for Your Product

Mylar lamination offers durable protection with a glossy or matte finish, making it ideal for products requiring moisture resistance and enhanced rigidity. UV coating provides a high-gloss, visually striking surface that enhances color vibrancy but offers less physical protection than lamination. Choosing between Mylar lamination and UV coating depends on whether your product prioritizes durability and longevity or aesthetic appeal and vibrant finish.

Mylar Lamination vs UV Coating Infographic

materialdif.com

materialdif.com