Die cutting Mylar offers precise, consistent shapes ideal for high-volume production, while laser cutting provides superior flexibility for intricate patterns and custom designs. Die cutting uses pre-made steel blades that ensure repeatability, whereas laser cutting relies on focused light beams, allowing for detailed and complex cuts without physical contact. Choosing between the two depends on the balance between production speed, design complexity, and material thickness.

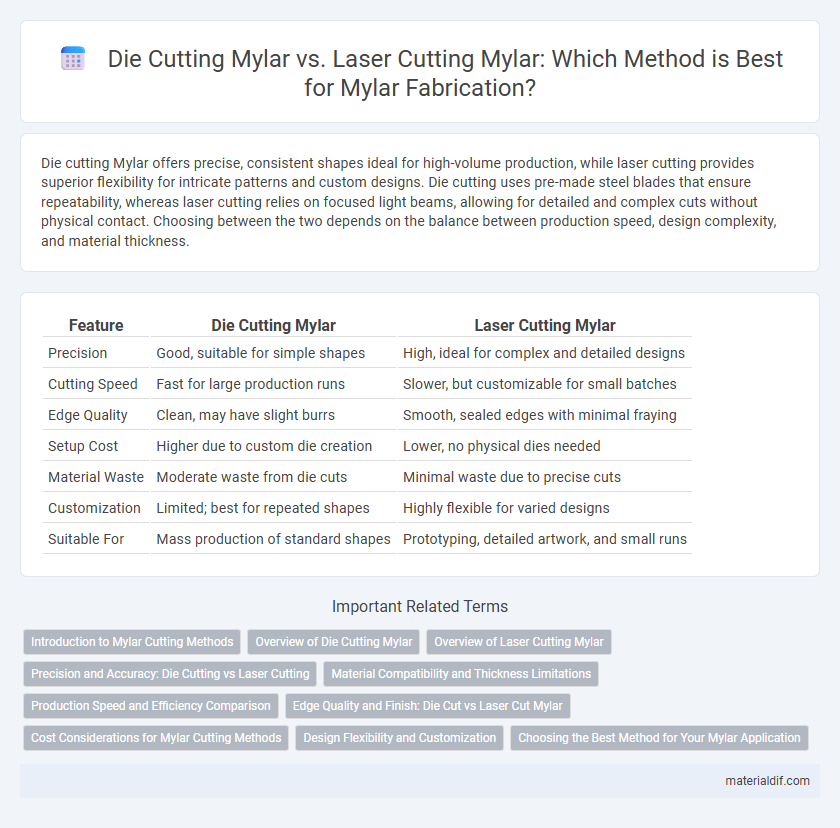

Table of Comparison

| Feature | Die Cutting Mylar | Laser Cutting Mylar |

|---|---|---|

| Precision | Good, suitable for simple shapes | High, ideal for complex and detailed designs |

| Cutting Speed | Fast for large production runs | Slower, but customizable for small batches |

| Edge Quality | Clean, may have slight burrs | Smooth, sealed edges with minimal fraying |

| Setup Cost | Higher due to custom die creation | Lower, no physical dies needed |

| Material Waste | Moderate waste from die cuts | Minimal waste due to precise cuts |

| Customization | Limited; best for repeated shapes | Highly flexible for varied designs |

| Suitable For | Mass production of standard shapes | Prototyping, detailed artwork, and small runs |

Introduction to Mylar Cutting Methods

Die cutting Mylar involves using a custom-shaped steel blade to precisely cut the material, ideal for high-volume production runs due to its repeatability and speed. Laser cutting Mylar utilizes concentrated laser beams to achieve intricate designs and fine details, providing superior accuracy and the ability to cut complex shapes without physical contact. Both methods offer unique advantages depending on the desired application, durability requirements, and production scale.

Overview of Die Cutting Mylar

Die cutting Mylar involves the use of a custom-shaped steel die to create precise and consistent cuts in Mylar sheets, making it ideal for high-volume production runs. This method offers excellent repeatability and clean edges, especially effective for simple to moderately complex shapes. Its cost-efficiency and speed make die cutting a preferred choice for applications like stickers, labels, and industrial components.

Overview of Laser Cutting Mylar

Laser cutting Mylar offers a precise and efficient method using a high-powered laser beam to cut intricate shapes and fine details with minimal material waste. This technique provides superior accuracy compared to die cutting, allowing for complex designs without the need for custom dies or physical tools. Laser cutting reduces production time and is ideal for short runs or prototyping, making it a versatile choice for various industrial and craft applications.

Precision and Accuracy: Die Cutting vs Laser Cutting

Die cutting Mylar offers high repeatability and consistent precision ideal for large production runs with uniform shapes, utilizing custom steel dies for clean edges. Laser cutting Mylar provides superior accuracy and intricate detail capabilities, enabling complex designs with tight tolerances due to its non-contact, computer-controlled beam. Both methods maintain precise dimensions, but laser cutting excels in flexibility and fine detail without tool wear, while die cutting is more cost-effective for mass production.

Material Compatibility and Thickness Limitations

Die cutting Mylar excels with thicker materials, handling up to 30 mils efficiently while maintaining clean edges without heat distortion. Laser cutting Mylar is best suited for thinner films, typically under 10 mils, to prevent melting or burning due to concentrated heat exposure. Material compatibility varies as die cutting accommodates multiple Mylar grades, whereas laser cutting's effectiveness depends on Mylar's heat tolerance and chemical composition.

Production Speed and Efficiency Comparison

Die cutting Mylar delivers faster production speeds due to its ability to perform high-volume, repeatable cuts with minimal setup time, making it ideal for mass production runs. Laser cutting Mylar offers greater precision and flexibility for intricate designs but operates slower and may require additional finishing steps, reducing overall efficiency in large-scale manufacturing. Prioritizing die cutting can significantly enhance throughput and cost-effectiveness where high efficiency and speed are critical.

Edge Quality and Finish: Die Cut vs Laser Cut Mylar

Die cutting Mylar produces clean, smooth edges with consistent thickness, ideal for high-volume production where precision and uniformity are essential. Laser cutting Mylar offers intricate designs with sharper cuts but can result in slightly melted or rougher edges due to heat exposure. The choice depends on the required edge finish, with die cutting preferred for crisp, uniform edges and laser cutting suited for detailed, complex shapes.

Cost Considerations for Mylar Cutting Methods

Die cutting Mylar typically offers lower upfront costs and faster production speeds, making it cost-effective for high-volume runs and simple shapes. Laser cutting Mylar incurs higher initial expenses due to advanced equipment but provides greater precision and flexibility for intricate designs, reducing waste and post-processing costs. Choosing between die cutting and laser cutting depends on the complexity, volume, and budget constraints of the Mylar cutting project.

Design Flexibility and Customization

Die cutting Mylar offers high precision for repetitive, simple shapes with cost-effective production runs, while laser cutting Mylar provides superior design flexibility for intricate and complex patterns, enabling detailed customization. Laser cutting allows for rapid prototyping without the need for custom dies, making it ideal for unique or low-volume projects. Die cutting excels in large-scale manufacturing where uniformity and speed are prioritized over complex design variations.

Choosing the Best Method for Your Mylar Application

Die cutting Mylar offers precise, repeatable shapes ideal for large-volume production runs, while laser cutting provides greater flexibility for intricate and custom designs with minimal material waste. Selecting the best method depends on the complexity of your Mylar application, production volume, and cost considerations. For high accuracy and detailed patterns, laser cutting Mylar excels, whereas die cutting Mylar is more cost-effective for straightforward, high-quantity jobs.

Die Cutting Mylar vs Laser Cutting Mylar Infographic

materialdif.com

materialdif.com