Mylar offers superior strength, durability, and resistance to moisture and oxygen compared to BOPP, making it ideal for long-term pet food packaging. BOPP provides excellent clarity and cost-effectiveness, but lacks the barrier properties necessary for preserving freshness in pet products. Choosing Mylar ensures extended shelf life and protection against environmental factors, crucial for maintaining pet food quality.

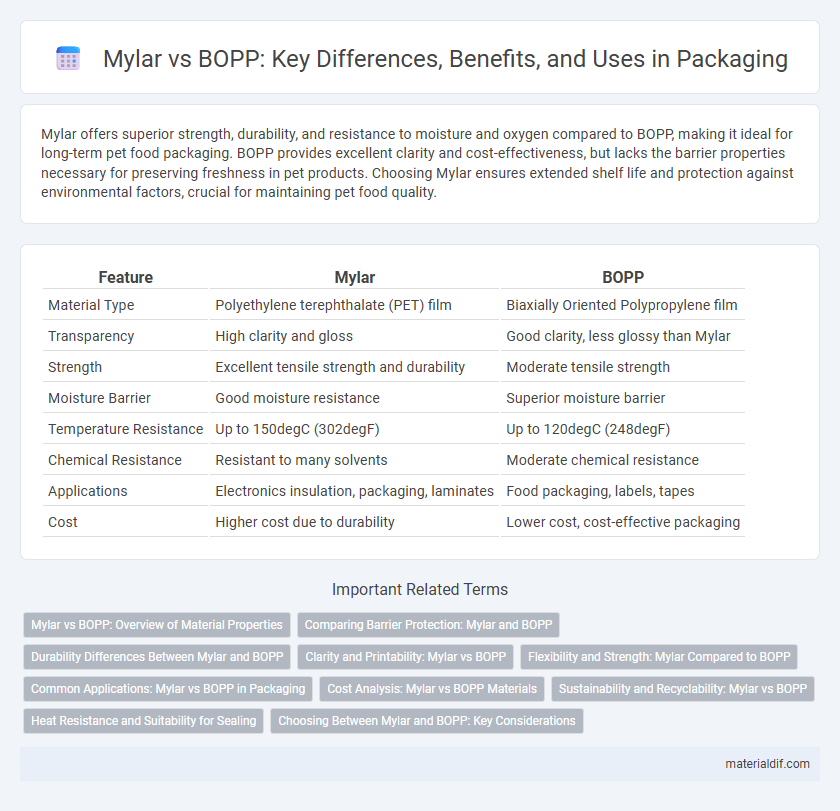

Table of Comparison

| Feature | Mylar | BOPP |

|---|---|---|

| Material Type | Polyethylene terephthalate (PET) film | Biaxially Oriented Polypropylene film |

| Transparency | High clarity and gloss | Good clarity, less glossy than Mylar |

| Strength | Excellent tensile strength and durability | Moderate tensile strength |

| Moisture Barrier | Good moisture resistance | Superior moisture barrier |

| Temperature Resistance | Up to 150degC (302degF) | Up to 120degC (248degF) |

| Chemical Resistance | Resistant to many solvents | Moderate chemical resistance |

| Applications | Electronics insulation, packaging, laminates | Food packaging, labels, tapes |

| Cost | Higher cost due to durability | Lower cost, cost-effective packaging |

Mylar vs BOPP: Overview of Material Properties

Mylar, a type of biaxially-oriented polyethylene terephthalate (BoPET), offers superior tensile strength, thermal stability, and chemical resistance compared to biaxially oriented polypropylene (BOPP). Mylar exhibits higher clarity and is more dimensionally stable, making it ideal for applications requiring durability and precision. In contrast, BOPP is more cost-effective and provides excellent moisture barrier properties but has comparatively lower heat resistance and mechanical strength.

Comparing Barrier Protection: Mylar and BOPP

Mylar provides superior barrier protection against moisture, oxygen, and light with a metallized polyethylene terephthalate (PET) film structure, making it ideal for sensitive product packaging. BOPP (Biaxially Oriented Polypropylene) offers good moisture resistance but lacks the same level of oxygen and light barrier properties compared to Mylar. This makes Mylar the preferred choice for applications requiring extended shelf life and enhanced product preservation.

Durability Differences Between Mylar and BOPP

Mylar, a polyester film known for its superior tensile strength and resistance to heat and chemicals, offers enhanced durability compared to BOPP (biaxially oriented polypropylene), which is more prone to tearing and deformation under stress. Mylar's dimensional stability and resistance to moisture make it ideal for demanding applications requiring long-lasting performance. In contrast, BOPP provides moderate durability suitable for less rigorous uses but lacks Mylar's robustness in harsh environmental conditions.

Clarity and Printability: Mylar vs BOPP

Mylar offers superior clarity with a high-gloss, transparent surface that enhances visual appeal in packaging and displays, making it ideal for applications requiring sharp, vibrant graphics. In comparison, BOPP provides good clarity but is often more matte, which can affect the brightness and sharpness of printed images. Mylar's smooth surface also supports better printability with various inks and coatings, resulting in more precise and durable prints than BOPP films.

Flexibility and Strength: Mylar Compared to BOPP

Mylar offers superior tensile strength and elasticity compared to BOPP, making it highly flexible for applications requiring durability and resilience under stress. BOPP, while more rigid, provides excellent clarity and moisture resistance but lacks the stretchability that Mylar films exhibit. The combination of Mylar's flexibility and strength makes it ideal for industrial uses such as electrical insulation and high-strength packaging.

Common Applications: Mylar vs BOPP in Packaging

Mylar, a polyester film known for its excellent tensile strength and barrier properties, is widely used in flexible packaging for food, pharmaceuticals, and electronics, providing superior moisture and oxygen resistance compared to BOPP (Biaxially Oriented Polypropylene). BOPP dominates applications requiring high clarity, stiffness, and cost-effectiveness, commonly found in snack packaging, labels, and adhesive tapes. The choice between Mylar and BOPP depends on specific packaging needs such as durability, barrier performance, and visual appeal.

Cost Analysis: Mylar vs BOPP Materials

Mylar offers higher durability and superior moisture resistance compared to BOPP, but comes at a higher cost per square meter, often ranging from 1.5 to 2 times the price of BOPP. BOPP is more cost-effective for large-scale packaging applications due to its lower raw material expenses and faster production rates, making it a preferred choice in budget-sensitive markets. Evaluating the trade-off between Mylar's enhanced barrier properties and BOPP's affordability is crucial for optimizing packaging investment.

Sustainability and Recyclability: Mylar vs BOPP

Mylar, a type of biaxially-oriented polyethylene terephthalate (BoPET), offers superior recyclability compared to BOPP (biaxially-oriented polypropylene) due to its polyester composition, which is widely accepted in plastic recycling streams. BOPP, while recyclable, often faces challenges in post-consumer recycling because of contamination and limited recycling facilities specialized for polypropylene films. Sustainability assessments favor Mylar for its longer lifecycle and lower environmental impact through efficient recycling processes and reduced resource consumption.

Heat Resistance and Suitability for Sealing

Mylar, a polyethylene terephthalate (PET) film, offers superior heat resistance compared to biaxially oriented polypropylene (BOPP), maintaining stability at temperatures up to 150degC, whereas BOPP typically withstands heat only up to 130degC. This enhanced thermal endurance makes Mylar more suitable for high-temperature sealing applications, ensuring reliable performance without deformation or melting. Mylar's robust heat resistance and dimensional stability result in stronger, more secure seals compared to the lower melting point and flexibility limitations of BOPP films.

Choosing Between Mylar and BOPP: Key Considerations

Choosing between Mylar and BOPP depends on factors such as barrier properties, durability, and cost-effectiveness. Mylar offers superior moisture and gas resistance, making it ideal for long-term food packaging and insulation applications, while BOPP provides good clarity, flexibility, and affordability for labels and flexible packaging. Evaluating specific application requirements, including temperature tolerance and printability, ensures the optimal selection between these polyester and polypropylene films.

Mylar vs BOPP Infographic

materialdif.com

materialdif.com