Mylar tape offers superior durability and resistance to moisture compared to Dacron tape, making it ideal for long-term applications. Its smooth, glossy surface ensures better adhesion and reduces the risk of fraying, unlike the fibrous texture of Dacron tape. Mylar tape's reflective properties also enhance visibility and heat resistance, providing functional advantages over traditional Dacron options.

Table of Comparison

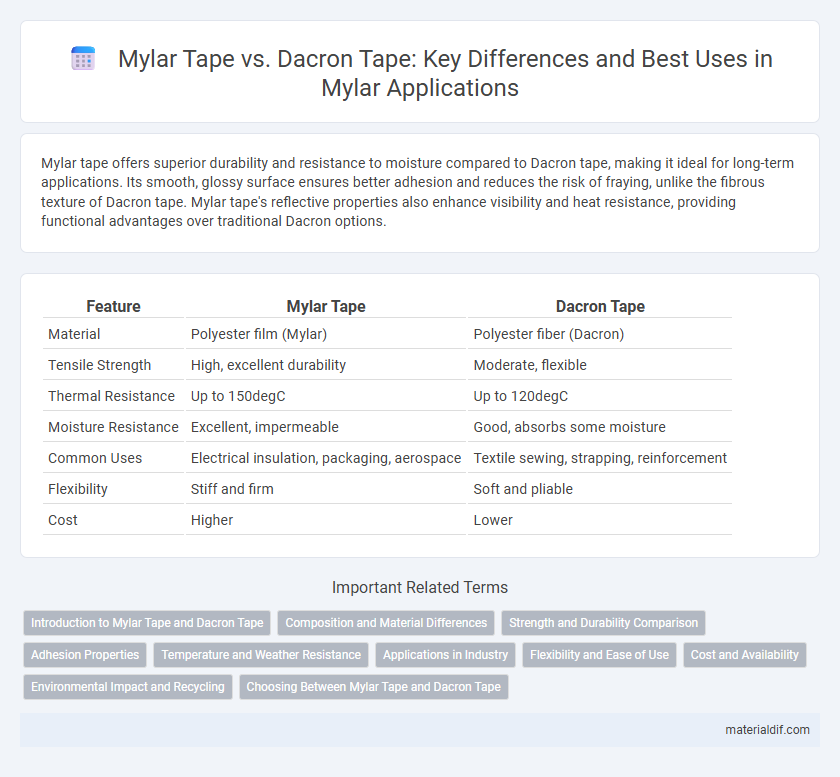

| Feature | Mylar Tape | Dacron Tape |

|---|---|---|

| Material | Polyester film (Mylar) | Polyester fiber (Dacron) |

| Tensile Strength | High, excellent durability | Moderate, flexible |

| Thermal Resistance | Up to 150degC | Up to 120degC |

| Moisture Resistance | Excellent, impermeable | Good, absorbs some moisture |

| Common Uses | Electrical insulation, packaging, aerospace | Textile sewing, strapping, reinforcement |

| Flexibility | Stiff and firm | Soft and pliable |

| Cost | Higher | Lower |

Introduction to Mylar Tape and Dacron Tape

Mylar tape, made from stretched polyester film, offers exceptional tensile strength, chemical resistance, and dimensional stability, making it ideal for electrical insulation and protective applications. Dacron tape, composed of woven polyester fibers, provides superior abrasion resistance and flexibility, often used in reinforcement and binding purposes. Both tapes excel in durability but differ in texture and specific use cases, with Mylar tape favored for smooth, heat-resistant surfaces and Dacron tape chosen for padded, impact-absorbing needs.

Composition and Material Differences

Mylar tape is composed primarily of biaxially-oriented polyethylene terephthalate (BoPET), known for its high tensile strength, chemical stability, and excellent insulating properties. In contrast, Dacron tape is made from woven polyethylene terephthalate fibers, offering greater flexibility and abrasion resistance but lower dimensional stability compared to Mylar. These material differences influence their respective applications, with Mylar tape favored for electrical insulation and structural reinforcement, while Dacron tape suits scenarios requiring stretchability and enhanced durability.

Strength and Durability Comparison

Mylar tape exhibits superior tensile strength and resistance to abrasion compared to Dacron tape, making it ideal for demanding applications requiring long-lasting durability. Mylar's polyester film structure provides excellent dimensional stability and resistance to chemicals, whereas Dacron tape, made from polyester fibers, tends to fray and degrade faster under harsh conditions. The enhanced strength-to-weight ratio and environmental resilience of Mylar tape ensure better performance in electrical insulation, packaging, and industrial uses over extended periods.

Adhesion Properties

Mylar tape offers superior adhesion properties compared to Dacron tape due to its polyester film backing, which provides excellent dimensional stability and a strong bond on various surfaces. The adhesive used on Mylar tape typically ensures long-lasting tackiness and resistance to environmental factors such as moisture and temperature variations. In contrast, Dacron tape, made from woven polyester fibers, often exhibits lower adhesion strength and can peel more easily under stress or exposure to harsh conditions.

Temperature and Weather Resistance

Mylar tape offers exceptional temperature resistance, maintaining structural integrity in extreme heat up to 250degC, making it ideal for high-temperature applications. In contrast, Dacron tape has moderate temperature tolerance, generally withstanding up to 150degC but showing reduced durability under prolonged heat exposure. Regarding weather resistance, Mylar's polyester film composition provides superior resistance to UV radiation, moisture, and chemical exposure compared to the more absorbent and less UV-resistant Dacron tape.

Applications in Industry

Mylar tape is widely used in electrical insulation, packaging, and aerospace industries due to its high tensile strength, chemical resistance, and excellent dielectric properties. Dacron tape finds applications primarily in marine and textile sectors where durability, moisture resistance, and flexibility are critical. Industrial processes requiring precise thermal insulation and mechanical stability often prefer Mylar tape, while fabric reinforcement and outdoor gear manufacturing rely on Dacron tape's superior abrasion resistance.

Flexibility and Ease of Use

Mylar tape offers superior flexibility compared to Dacron tape, making it ideal for applications requiring precise conformability to irregular surfaces. Its smooth texture enhances ease of handling and application, reducing installation time and effort. In contrast, Dacron tape, while durable, tends to be stiffer and less adaptable, which can complicate use in tight or intricate spaces.

Cost and Availability

Mylar tape generally offers a more cost-effective solution compared to Dacron tape, making it favored in budget-sensitive applications. It is widely available through numerous industrial suppliers, ensuring easy procurement for various manufacturing needs. Dacron tape, while slightly more expensive, may have limited availability due to specialized use cases, impacting overall accessibility.

Environmental Impact and Recycling

Mylar tape, made from polyethylene terephthalate (PET), offers superior recyclability compared to Dacron tape, which is polyester-based but often blended with other materials that complicate recycling processes. The environmental impact of Mylar tape is lower because PET can be efficiently recycled in established municipal programs, reducing landfill waste and resource consumption. In contrast, Dacron tape's blended fibers hinder biodegradability and recycling, contributing to longer-lasting environmental pollution.

Choosing Between Mylar Tape and Dacron Tape

Choosing between Mylar tape and Dacron tape depends on specific application requirements such as tensile strength, temperature resistance, and flexibility. Mylar tape offers superior electrical insulation, heat resistance up to 150degC, and excellent dimensional stability, making it ideal for electronic and aerospace uses. Dacron tape, made from polyester fibers, provides higher elasticity and tear resistance, better suited for textile reinforcement and applications needing durability under mechanical stress.

Mylar Tape vs Dacron Tape Infographic

materialdif.com

materialdif.com