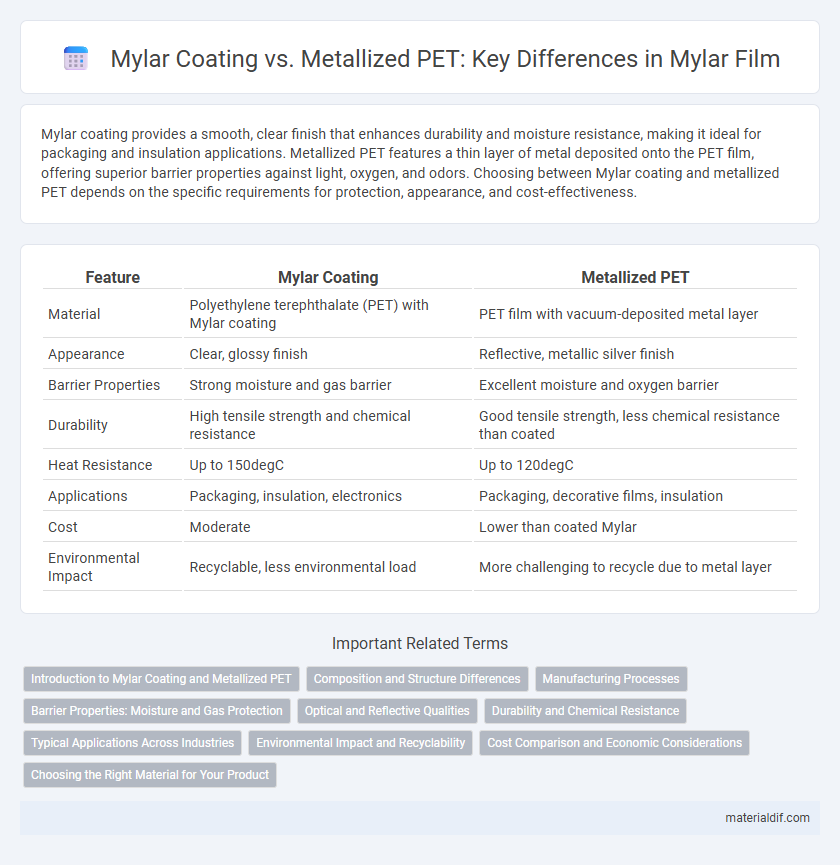

Mylar coating provides a smooth, clear finish that enhances durability and moisture resistance, making it ideal for packaging and insulation applications. Metallized PET features a thin layer of metal deposited onto the PET film, offering superior barrier properties against light, oxygen, and odors. Choosing between Mylar coating and metallized PET depends on the specific requirements for protection, appearance, and cost-effectiveness.

Table of Comparison

| Feature | Mylar Coating | Metallized PET |

|---|---|---|

| Material | Polyethylene terephthalate (PET) with Mylar coating | PET film with vacuum-deposited metal layer |

| Appearance | Clear, glossy finish | Reflective, metallic silver finish |

| Barrier Properties | Strong moisture and gas barrier | Excellent moisture and oxygen barrier |

| Durability | High tensile strength and chemical resistance | Good tensile strength, less chemical resistance than coated |

| Heat Resistance | Up to 150degC | Up to 120degC |

| Applications | Packaging, insulation, electronics | Packaging, decorative films, insulation |

| Cost | Moderate | Lower than coated Mylar |

| Environmental Impact | Recyclable, less environmental load | More challenging to recycle due to metal layer |

Introduction to Mylar Coating and Metallized PET

Mylar coating refers to a polyester film treated with a protective layer that enhances durability, moisture resistance, and thermal stability, making it suitable for packaging and insulation applications. Metallized PET involves applying a thin metal layer, usually aluminum, onto polyester film, which improves barrier properties, reflectivity, and aesthetic appeal in packaging and decorative uses. Both Mylar coating and metallized PET utilize polyester as a base but differ significantly in their functional enhancements and industrial applications.

Composition and Structure Differences

Mylar coating typically consists of a polyethylene terephthalate (PET) base film coated with a thin layer of acrylic or urethane to enhance durability and chemical resistance. Metallized PET, in contrast, involves vacuum deposition of a metal, usually aluminum, onto the PET film, creating a reflective, conductive surface. The primary structural difference lies in Mylar coating's polymer-based layer versus Metallized PET's metallic layer, influencing their applications in insulation, packaging, and electronics.

Manufacturing Processes

Mylar coating involves applying a thin polymer layer that enhances barrier properties and durability, typically through extrusion or solvent-based coating methods. Metallized PET manufacturing uses vacuum deposition to bond a fine metal layer, such as aluminum, onto the film's surface, imparting reflective and conductive characteristics. Both processes require precise control of temperature and tension to maintain film integrity and performance.

Barrier Properties: Moisture and Gas Protection

Mylar coating offers superior moisture and gas barrier properties compared to metallized PET due to its uniform polymer layer that effectively prevents permeation. While metallized PET provides good gas resistance through a thin metal layer, it can suffer from pinhole defects reducing its barrier efficiency against moisture. Mylar coatings maintain consistent protection in high humidity environments, making them ideal for applications requiring reliable long-term preservation of contents.

Optical and Reflective Qualities

Mylar coating enhances optical clarity and provides a smooth, transparent surface with high light transmission, making it ideal for applications requiring optical precision. Metallized PET, on the other hand, offers superior reflective qualities due to its thin metal layer, achieving reflectance levels up to 95%, which is essential for insulation, solar, and lighting uses. The choice between Mylar coating and metallized PET depends on whether transparency or reflectivity is critical for the application.

Durability and Chemical Resistance

Mylar coating offers superior durability due to its enhanced resistance to abrasion and environmental stress, making it ideal for long-term applications. Metallized PET, while providing excellent barrier properties and a reflective surface, is more susceptible to scratching and chemical degradation over time. The chemical resistance of Mylar coating ensures protection against solvents and oils, outperforming metallized PET in harsh chemical environments.

Typical Applications Across Industries

Mylar coating is widely used in packaging, insulation, and electrical applications due to its excellent chemical resistance and flexibility, making it ideal for food wraps, protective coverings, and capacitor films. Metallized PET finds typical applications in reflective insulation, decorative packaging, and solar control films, benefiting industries such as construction, consumer goods, and automotive for its high reflectivity and barrier properties. Both materials serve critical roles in electronics, aerospace, and printing industries, with Mylar coating often preferred for durability and metallized PET for enhanced visual appeal and light reflectance.

Environmental Impact and Recyclability

Mylar coating offers enhanced recyclability compared to metallized PET, as it avoids the use of metal layers that complicate recycling processes. Metallized PET involves aluminum deposition, which increases environmental impact due to energy-intensive production and challenges in material separation during recycling. Choosing Mylar-coated films reduces landfill waste and supports more sustainable disposal methods, aligning with eco-friendly packaging initiatives.

Cost Comparison and Economic Considerations

Mylar coating generally offers a lower-cost alternative compared to metallized PET due to simpler production processes and reduced material expenses. Metallized PET, while more expensive because of added metal layers, provides superior barrier properties and durability that can justify higher initial investments in long-term applications. Evaluating economic considerations involves balancing upfront manufacturing costs with product performance and lifespan requirements to optimize overall value.

Choosing the Right Material for Your Product

Mylar coating provides a strong, flexible barrier with excellent chemical resistance and moisture protection, ideal for packaging sensitive products. Metallized PET offers superior reflectivity and light barrier properties, making it suitable for applications requiring enhanced visual aesthetics and extended shelf life. Selecting between Mylar coating and metallized PET depends on specific product needs such as durability, environmental exposure, and functional requirements.

Mylar Coating vs Metallized PET Infographic

materialdif.com

materialdif.com