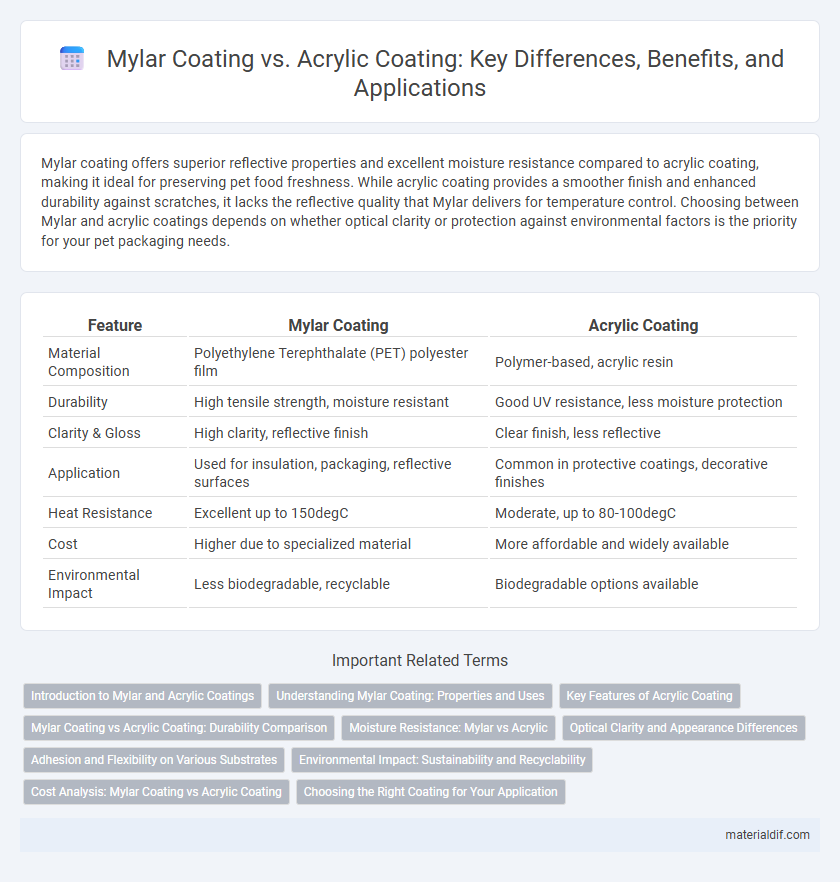

Mylar coating offers superior reflective properties and excellent moisture resistance compared to acrylic coating, making it ideal for preserving pet food freshness. While acrylic coating provides a smoother finish and enhanced durability against scratches, it lacks the reflective quality that Mylar delivers for temperature control. Choosing between Mylar and acrylic coatings depends on whether optical clarity or protection against environmental factors is the priority for your pet packaging needs.

Table of Comparison

| Feature | Mylar Coating | Acrylic Coating |

|---|---|---|

| Material Composition | Polyethylene Terephthalate (PET) polyester film | Polymer-based, acrylic resin |

| Durability | High tensile strength, moisture resistant | Good UV resistance, less moisture protection |

| Clarity & Gloss | High clarity, reflective finish | Clear finish, less reflective |

| Application | Used for insulation, packaging, reflective surfaces | Common in protective coatings, decorative finishes |

| Heat Resistance | Excellent up to 150degC | Moderate, up to 80-100degC |

| Cost | Higher due to specialized material | More affordable and widely available |

| Environmental Impact | Less biodegradable, recyclable | Biodegradable options available |

Introduction to Mylar and Acrylic Coatings

Mylar coating is a polyester film known for its exceptional durability, high tensile strength, and superior moisture resistance, making it ideal for protective and insulating applications. Acrylic coating, composed of polymer-based substances, offers excellent UV resistance, clarity, and flexibility, commonly used for decorative finishes and protective layers in automotive and packaging industries. Both coatings serve distinct functions where Mylar excels in structural protection, while acrylic coatings prioritize aesthetic appeal and weather resistance.

Understanding Mylar Coating: Properties and Uses

Mylar coating offers exceptional tensile strength, chemical resistance, and impermeability, making it ideal for applications requiring durable, lightweight, and moisture-resistant barriers. Unlike acrylic coating, which provides good UV protection and weather resistance but lower chemical resistance, Mylar excels in electronic insulation, packaging, and reflective insulation due to its polyester film base. The unique properties of Mylar coating, including its thermal stability and high dielectric strength, enable its use in aerospace, electrical, and food packaging industries where long-lasting performance is essential.

Key Features of Acrylic Coating

Acrylic coating offers superior UV resistance and flexibility compared to Mylar coating, making it ideal for outdoor applications exposed to sunlight and temperature variations. Its excellent adhesion properties allow for smooth, durable finishes on various substrates, enhancing longevity and aesthetic appeal. Acrylic coatings also provide better moisture resistance and color retention, ensuring consistent performance over time.

Mylar Coating vs Acrylic Coating: Durability Comparison

Mylar coating exhibits superior durability compared to acrylic coating due to its high tensile strength and resistance to moisture, UV rays, and chemicals, making it ideal for long-lasting protective applications. Acrylic coatings tend to degrade faster when exposed to harsh environmental conditions, losing adhesion and clarity over time. The enhanced durability of Mylar coating supports extended usage in industrial and outdoor settings where maintaining structural integrity and visual quality is critical.

Moisture Resistance: Mylar vs Acrylic

Mylar coating offers superior moisture resistance due to its dense polyester film structure that effectively blocks water vapor penetration, making it ideal for protecting sensitive materials in humid environments. In contrast, acrylic coatings provide moderate moisture resistance but are more permeable to moisture over time, reducing their effectiveness in prolonged exposure to damp conditions. For applications requiring long-lasting barrier properties against moisture, Mylar is the preferred choice over acrylic coatings.

Optical Clarity and Appearance Differences

Mylar coating offers superior optical clarity compared to acrylic coating due to its smooth, uniform surface that minimizes light distortion and enhances transparency. Acrylic coatings, while durable and flexible, tend to have a slightly matte finish that can reduce clarity and affect the overall appearance by diffusing light more than Mylar. Mylar's glossy, reflective properties contribute to a sharper, more vibrant visual effect, making it preferred for applications where clear, high-quality optics are essential.

Adhesion and Flexibility on Various Substrates

Mylar coating exhibits superior adhesion and flexibility on diverse substrates such as metal, glass, and plastic due to its polyester base, which ensures strong bonding and durability under stress. Acrylic coating, while offering good clarity and UV resistance, tends to be less flexible, making it more prone to cracking on flexible or uneven surfaces. The polyester composition of Mylar enables it to maintain adhesion integrity and flexibility, especially in applications requiring dynamic movement or thermal cycling.

Environmental Impact: Sustainability and Recyclability

Mylar coating, made from biaxially-oriented polyethylene terephthalate (BoPET), offers enhanced durability and superior barrier properties, contributing to longer product life cycles and reduced waste. Unlike acrylic coatings, Mylar is more easily recyclable and can be separated efficiently during recycling processes, minimizing environmental contamination. The sustainability of Mylar coatings is further supported by their resistance to degradation, which reduces the frequency of replacements and lowers overall resource consumption.

Cost Analysis: Mylar Coating vs Acrylic Coating

Mylar coating typically offers a higher initial cost compared to acrylic coating due to advanced materials and manufacturing processes. However, its superior durability and resistance to UV degradation can reduce long-term maintenance and replacement expenses. Acrylic coatings present a lower upfront investment but may incur higher costs over time because of their comparatively shorter lifespan and susceptibility to environmental wear.

Choosing the Right Coating for Your Application

Mylar coating offers exceptional tensile strength, chemical resistance, and moisture barrier properties, making it ideal for applications requiring durability and protection from environmental factors. Acrylic coating provides excellent UV resistance and flexibility, suitable for surfaces exposed to sunlight and frequent handling. Selecting the right coating depends on the specific demands of your project, balancing factors like environmental exposure, mechanical stress, and desired longevity.

Mylar Coating vs Acrylic Coating Infographic

materialdif.com

materialdif.com