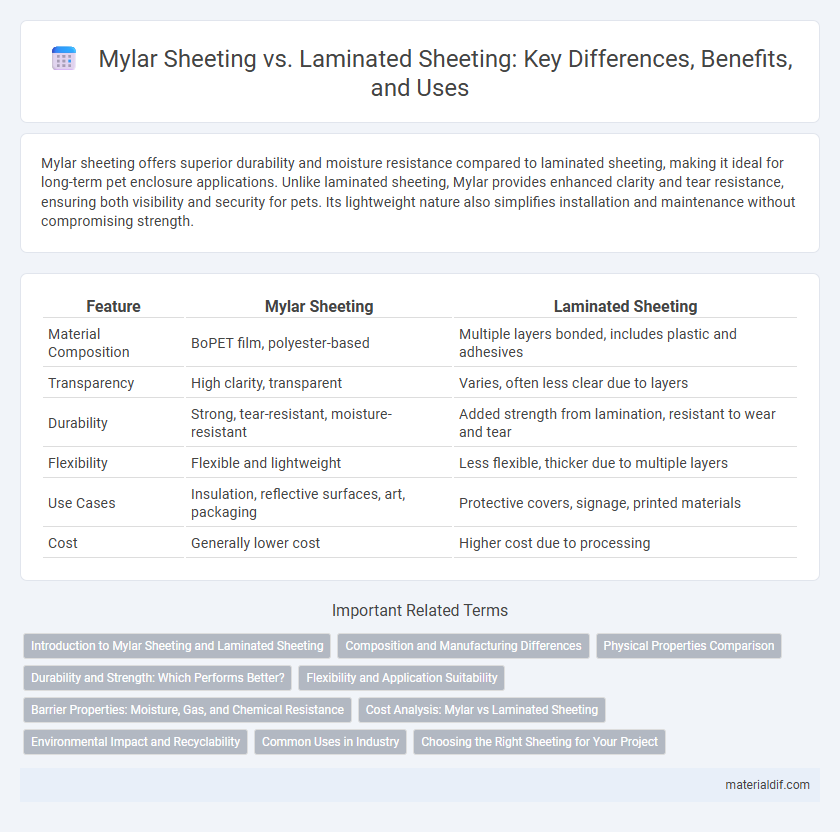

Mylar sheeting offers superior durability and moisture resistance compared to laminated sheeting, making it ideal for long-term pet enclosure applications. Unlike laminated sheeting, Mylar provides enhanced clarity and tear resistance, ensuring both visibility and security for pets. Its lightweight nature also simplifies installation and maintenance without compromising strength.

Table of Comparison

| Feature | Mylar Sheeting | Laminated Sheeting |

|---|---|---|

| Material Composition | BoPET film, polyester-based | Multiple layers bonded, includes plastic and adhesives |

| Transparency | High clarity, transparent | Varies, often less clear due to layers |

| Durability | Strong, tear-resistant, moisture-resistant | Added strength from lamination, resistant to wear and tear |

| Flexibility | Flexible and lightweight | Less flexible, thicker due to multiple layers |

| Use Cases | Insulation, reflective surfaces, art, packaging | Protective covers, signage, printed materials |

| Cost | Generally lower cost | Higher cost due to processing |

Introduction to Mylar Sheeting and Laminated Sheeting

Mylar sheeting, a polyester film known for its high tensile strength, clarity, and resistance to moisture and chemicals, is commonly used in packaging, insulation, and protective covers. Laminated sheeting involves bonding multiple layers, often including Mylar, with adhesives or heat to enhance durability, barrier properties, and structural integrity. Mylar sheeting provides excellent baseline performance, while laminated sheeting offers superior protection in demanding environments through its multi-layer construction.

Composition and Manufacturing Differences

Mylar sheeting is composed primarily of stretched polyethylene terephthalate (PET) film, produced through a biaxial orientation process that enhances strength, clarity, and dimensional stability. Laminated sheeting consists of multiple layers bonded together, often combining Mylar with other materials like polyethylene or aluminum foil to improve barrier properties and durability. While Mylar focuses on high tensile strength and optical clarity due to its uniform PET structure, laminated sheeting offers customized performance through its composite layering, impacting flexibility, moisture resistance, and chemical protection.

Physical Properties Comparison

Mylar sheeting offers superior tensile strength and excellent dimensional stability compared to laminated sheeting, which often incorporates multiple layers that can reduce overall flexibility. Mylar's low moisture absorption and high dielectric strength make it ideal for electronic and insulation applications, whereas laminated sheeting may be prone to delamination under stress or prolonged exposure to humidity. Thermal resistance is another key advantage of Mylar sheeting, maintaining integrity at temperatures up to 150degC, contrasting with laminated sheeting that can degrade or warp under similar thermal conditions.

Durability and Strength: Which Performs Better?

Mylar sheeting offers superior durability and strength compared to laminated sheeting due to its polyester film composition, which resists tearing, moisture, and UV exposure more effectively. Laminated sheeting, while providing enhanced protection through layered materials, often falls short in long-term abrasion resistance and structural integrity under extreme conditions. For applications requiring high tensile strength and prolonged durability, Mylar sheeting consistently outperforms laminated alternatives.

Flexibility and Application Suitability

Mylar sheeting offers superior flexibility compared to laminated sheeting, making it ideal for applications requiring frequent bending or folding, such as flexible packaging and electronic insulation. Laminated sheeting provides enhanced durability and moisture resistance, suited for rigid or semi-rigid uses like protective covers and industrial packaging. Selecting between Mylar and laminated sheeting depends on balancing flexibility needs with environmental protection and structural strength.

Barrier Properties: Moisture, Gas, and Chemical Resistance

Mylar sheeting offers superior barrier properties, providing exceptional resistance to moisture, gases, and chemicals due to its biaxially-oriented polyethylene terephthalate (BoPET) composition. Laminated sheeting combines multiple layers, enhancing overall durability but often compromises specific barrier performance depending on the materials used in lamination. When selecting for moisture and gas impermeability in critical applications, Mylar's intrinsic low permeability makes it the preferred choice over most laminated alternatives.

Cost Analysis: Mylar vs Laminated Sheeting

Mylar sheeting generally offers a lower upfront cost compared to laminated sheeting, making it a cost-effective option for budgets focused on affordability. While laminated sheeting provides enhanced durability and moisture resistance, its higher price can impact overall project expenses. Evaluating lifecycle costs reveals that Mylar may require more frequent replacement, but initial savings often outweigh the benefits of longer-lasting laminated sheets in short-term applications.

Environmental Impact and Recyclability

Mylar sheeting, primarily composed of biaxially-oriented polyethylene terephthalate (BoPET), offers superior environmental benefits compared to laminated sheeting due to its higher recyclability and reduced chemical use. Laminated sheeting often combines multiple layers of plastic and adhesives, complicating recycling processes and increasing landfill waste. Choosing Mylar sheeting supports sustainable packaging by enabling more efficient material recovery and lowering the overall ecological footprint.

Common Uses in Industry

Mylar sheeting is widely used in industries such as electronics, packaging, and insulation due to its high tensile strength, electrical insulation properties, and moisture resistance. Laminated sheeting, combining Mylar with other materials like aluminum or polyethylene, is preferred for packaging applications requiring enhanced barrier protection against oxygen, light, and contaminants. Both types serve critical roles in manufacturing flexible printed circuits, food packaging, and protective coverings, with laminated sheeting offering superior durability and functional layering for specialized industrial needs.

Choosing the Right Sheeting for Your Project

Mylar sheeting offers exceptional durability, chemical resistance, and clarity, making it ideal for applications requiring long-term protection and precision. Laminated sheeting combines multiple layers, enhancing strength and providing better tear resistance and waterproof properties, suitable for heavy-duty or outdoor projects. Selecting the right sheeting depends on the project's environmental exposure, flexibility needs, and required strength, with Mylar excelling in transparency and chemical stability while laminated options outperform in impact resistance.

Mylar Sheeting vs Laminated Sheeting Infographic

materialdif.com

materialdif.com