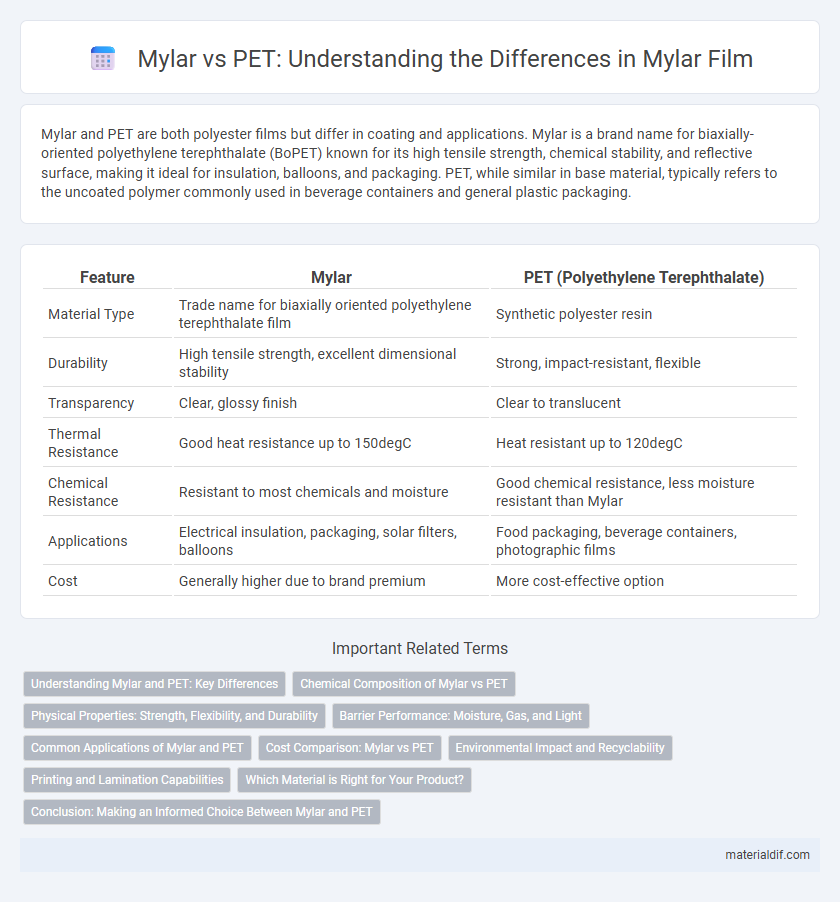

Mylar and PET are both polyester films but differ in coating and applications. Mylar is a brand name for biaxially-oriented polyethylene terephthalate (BoPET) known for its high tensile strength, chemical stability, and reflective surface, making it ideal for insulation, balloons, and packaging. PET, while similar in base material, typically refers to the uncoated polymer commonly used in beverage containers and general plastic packaging.

Table of Comparison

| Feature | Mylar | PET (Polyethylene Terephthalate) |

|---|---|---|

| Material Type | Trade name for biaxially oriented polyethylene terephthalate film | Synthetic polyester resin |

| Durability | High tensile strength, excellent dimensional stability | Strong, impact-resistant, flexible |

| Transparency | Clear, glossy finish | Clear to translucent |

| Thermal Resistance | Good heat resistance up to 150degC | Heat resistant up to 120degC |

| Chemical Resistance | Resistant to most chemicals and moisture | Good chemical resistance, less moisture resistant than Mylar |

| Applications | Electrical insulation, packaging, solar filters, balloons | Food packaging, beverage containers, photographic films |

| Cost | Generally higher due to brand premium | More cost-effective option |

Understanding Mylar and PET: Key Differences

Mylar, a brand name for biaxially oriented polyethylene terephthalate (BoPET), differs from standard PET primarily in its enhanced tensile strength, chemical resistance, and superior reflective properties. While PET is widely used for packaging and bottles, Mylar's specialized manufacturing process results in a film with higher durability and flexibility, making it ideal for insulation, electronics, and safety applications. The key distinction lies in Mylar's biaxial orientation, which improves dimensional stability and barrier qualities compared to regular PET sheets.

Chemical Composition of Mylar vs PET

Mylar, a brand name for biaxially oriented polyethylene terephthalate (BoPET), shares the same chemical composition as standard PET, both being polyester polymers derived from the polymerization of terephthalic acid and ethylene glycol. The key difference lies in Mylar's biaxial orientation process, which aligns polymer chains in two directions, enhancing its tensile strength, clarity, and barrier properties compared to unoriented PET films. This structural distinction, rather than chemical composition, accounts for Mylar's superior performance in applications requiring durability and chemical resistance.

Physical Properties: Strength, Flexibility, and Durability

Mylar, a brand name for biaxially-oriented polyethylene terephthalate (BoPET), exhibits high tensile strength and superior dimensional stability compared to standard PET films. Its flexibility allows it to withstand significant deformation without breaking, making it ideal for applications requiring durable, lightweight materials. The enhanced durability of Mylar results from its crystallized structure, providing resistance to moisture, chemicals, and temperature variations, outperforming conventional PET in demanding environments.

Barrier Performance: Moisture, Gas, and Light

Mylar, a brand of biaxially-oriented polyethylene terephthalate (BoPET), offers superior barrier performance compared to standard PET films, effectively limiting moisture, gas, and light permeability. This enhanced barrier property makes Mylar ideal for packaging applications requiring extended shelf life and protection against oxygen, water vapor, and ultraviolet radiation. The dense molecular structure of Mylar significantly reduces transmission rates, outperforming conventional PET films in maintaining product integrity.

Common Applications of Mylar and PET

Mylar, a brand name for biaxially oriented polyethylene terephthalate (BoPET), is widely used in insulation, reflective surfaces, and flexible packaging due to its high tensile strength and thermal stability. PET, while sharing similar chemical properties, finds common applications in beverage bottles, food containers, and synthetic fibers owing to its excellent impact resistance and clarity. Both materials are essential in electronics, with Mylar often preferred for capacitor films and PET for protective coatings and laminates.

Cost Comparison: Mylar vs PET

Mylar typically offers a more cost-effective solution compared to PET due to its lower manufacturing expenses and versatility in various applications. PET involves higher raw material and processing costs, making it less economical for large-scale or budget-sensitive projects. Choosing Mylar over PET can result in significant savings without compromising durability or performance in packaging and insulation uses.

Environmental Impact and Recyclability

Mylar, a brand name for biaxially-oriented polyethylene terephthalate (BoPET), shares a similar chemical composition with PET but differs in manufacturing processes that affect its environmental footprint. Compared to standard PET, Mylar films often exhibit enhanced durability and chemical resistance, which can lead to longer product lifespans but may complicate recycling due to added coatings or metallization. Both Mylar and PET are recyclable materials, yet the presence of special coatings on Mylar can reduce recyclability rates and require specialized processing facilities to manage their environmental impact effectively.

Printing and Lamination Capabilities

Mylar, a brand of biaxially-oriented polyethylene terephthalate (PET), offers superior printing quality due to its smooth, glossy surface that enhances ink adhesion and vibrancy compared to standard PET films. In lamination, Mylar's high tensile strength and thermal stability provide durable, wrinkle-free bonds, making it ideal for applications requiring strong, long-lasting layers. PET films generally have lower clarity and less resistance to heat during lamination, resulting in reduced print sharpness and potential deformation.

Which Material is Right for Your Product?

Mylar, a brand name for biaxially-oriented polyethylene terephthalate (BoPET), offers superior clarity, tensile strength, and thermal stability compared to standard PET films, making it ideal for high-performance packaging and insulation applications. PET, while more cost-effective and flexible, suits products requiring durability with less emphasis on heat resistance or dimensional stability. Choosing between Mylar and PET depends on your product's need for barrier properties, mechanical strength, and temperature tolerance, with Mylar excelling in premium uses and PET serving everyday packaging needs effectively.

Conclusion: Making an Informed Choice Between Mylar and PET

Mylar and PET both offer excellent durability and clarity, but Mylar excels in heat resistance and chemical stability, making it ideal for high-performance industrial applications. PET provides superior flexibility and cost efficiency, better suited for everyday packaging and consumer goods. Choosing between Mylar and PET depends on specific requirements like temperature tolerance, mechanical stress, and budget constraints to optimize performance and value.

Mylar vs PET Infographic

materialdif.com

materialdif.com