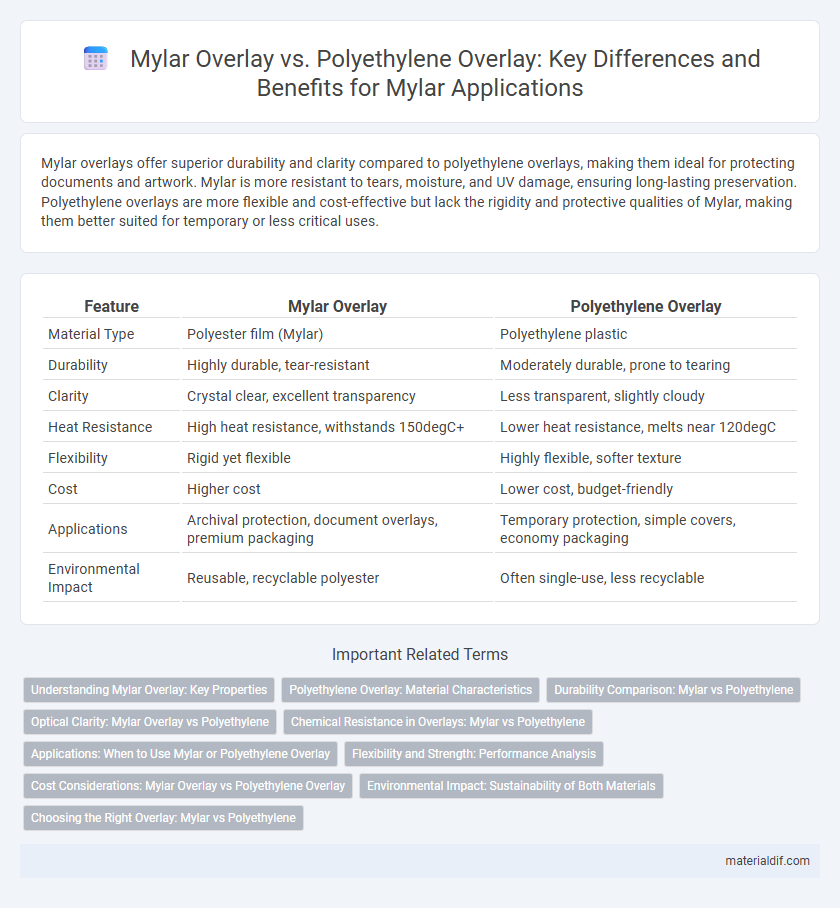

Mylar overlays offer superior durability and clarity compared to polyethylene overlays, making them ideal for protecting documents and artwork. Mylar is more resistant to tears, moisture, and UV damage, ensuring long-lasting preservation. Polyethylene overlays are more flexible and cost-effective but lack the rigidity and protective qualities of Mylar, making them better suited for temporary or less critical uses.

Table of Comparison

| Feature | Mylar Overlay | Polyethylene Overlay |

|---|---|---|

| Material Type | Polyester film (Mylar) | Polyethylene plastic |

| Durability | Highly durable, tear-resistant | Moderately durable, prone to tearing |

| Clarity | Crystal clear, excellent transparency | Less transparent, slightly cloudy |

| Heat Resistance | High heat resistance, withstands 150degC+ | Lower heat resistance, melts near 120degC |

| Flexibility | Rigid yet flexible | Highly flexible, softer texture |

| Cost | Higher cost | Lower cost, budget-friendly |

| Applications | Archival protection, document overlays, premium packaging | Temporary protection, simple covers, economy packaging |

| Environmental Impact | Reusable, recyclable polyester | Often single-use, less recyclable |

Understanding Mylar Overlay: Key Properties

Mylar overlay is a polyester film known for its exceptional clarity, tensile strength, and resistance to moisture, chemicals, and temperature fluctuations, making it ideal for protective covers and laminations. Compared to polyethylene overlays, Mylar offers superior dimensional stability and durability, ensuring long-lasting protection without yellowing or warping over time. These properties enable Mylar overlays to maintain visual quality and structural integrity in demanding applications such as maps, signage, and technical documents.

Polyethylene Overlay: Material Characteristics

Polyethylene overlay exhibits superior flexibility and impact resistance compared to Mylar, making it ideal for protective applications requiring durability. Its chemical inertness ensures resistance to moisture, oils, and solvents, enhancing longevity in various environments. Additionally, polyethylene's lightweight nature and ease of processing contribute to cost-effective manufacturing and versatility in industrial uses.

Durability Comparison: Mylar vs Polyethylene

Mylar overlays exhibit superior durability compared to polyethylene due to their enhanced resistance to tearing, punctures, and UV degradation. Mylar's polyester composition maintains structural integrity under prolonged exposure to heat and moisture, whereas polyethylene overlays tend to degrade faster and become brittle over time. This makes Mylar the preferred choice for applications requiring long-lasting protective barriers and high-performance film durability.

Optical Clarity: Mylar Overlay vs Polyethylene

Mylar overlays offer superior optical clarity compared to polyethylene overlays due to their higher transparency and reduced light distortion. The polyester base of Mylar enables sharper image quality and better color fidelity, making it ideal for applications requiring precise visual detail. Polyethylene overlays typically exhibit more haze and lower clarity, which can impede optimal viewing experiences in critical environments.

Chemical Resistance in Overlays: Mylar vs Polyethylene

Mylar overlays exhibit superior chemical resistance compared to polyethylene overlays, effectively withstanding exposure to acids, solvents, and oils without degradation. Polyethylene overlays, while flexible and cost-effective, tend to show vulnerability to strong chemicals, leading to swelling or surface damage over time. This chemical resilience makes Mylar the preferred choice for applications requiring durable and long-lasting protective films in harsh environments.

Applications: When to Use Mylar or Polyethylene Overlay

Mylar overlays are ideal for applications requiring high durability, chemical resistance, and clarity, such as protective screens, labels, and decals exposed to harsh environments. Polyethylene overlays excel in flexible packaging, surface protection, and moisture barrier applications due to their cost-effectiveness and abrasion resistance. Choosing between Mylar and polyethylene overlays depends on the specific need for strength, transparency, and environmental resistance in industrial or consumer products.

Flexibility and Strength: Performance Analysis

Mylar overlays offer superior flexibility and tensile strength compared to polyethylene overlays, making them ideal for applications requiring durability and resilience under stress. Their polyester composition provides excellent resistance to tearing and deformation, while polyethylene overlays, although cost-effective, tend to be less flexible and prone to stretching or cracking over time. The enhanced mechanical properties of Mylar ensure long-lasting performance in protective coatings and laminations where both flexibility and strength are critical.

Cost Considerations: Mylar Overlay vs Polyethylene Overlay

Mylar overlays typically cost more than polyethylene overlays due to Mylar's superior durability and heat resistance, which justifies the higher price in high-performance applications. Polyethylene overlays offer a more budget-friendly option, making them suitable for less demanding uses where cost savings are prioritized. Evaluating the total lifecycle cost, including replacement frequency and durability, is essential when choosing between Mylar and polyethylene overlays.

Environmental Impact: Sustainability of Both Materials

Mylar overlays are made from biaxially-oriented polyethylene terephthalate (BoPET), which is recyclable but has a higher carbon footprint due to energy-intensive manufacturing processes. Polyethylene overlays, derived from low-density polyethylene (LDPE), tend to be less energy-demanding to produce and are more widely accepted in recycling streams, contributing to improved sustainability. The environmental impact of both materials depends on end-of-life management, with polyethylene offering better biodegradability potential and Mylar providing superior durability for extended use.

Choosing the Right Overlay: Mylar vs Polyethylene

Mylar overlays offer superior clarity and durability compared to polyethylene, making them ideal for preserving documents and artworks with long-term protection against moisture and UV damage. Polyethylene overlays are more flexible and cost-effective, suitable for temporary covers or applications requiring light protection and frequent handling. Selecting the right overlay depends on the need for durability and clarity versus budget constraints and flexibility in use.

Mylar Overlay vs Polyethylene Overlay Infographic

materialdif.com

materialdif.com