Mylar tape offers excellent electrical insulation and thermal stability, making it ideal for high-temperature applications, while Kapton tape provides superior flexibility and resistance to chemicals and radiation. Mylar tape tends to be more cost-effective and offers better moisture resistance compared to Kapton tape. Both tapes are essential in electronics and aerospace, but Mylar is preferred when durability and cost are critical factors.

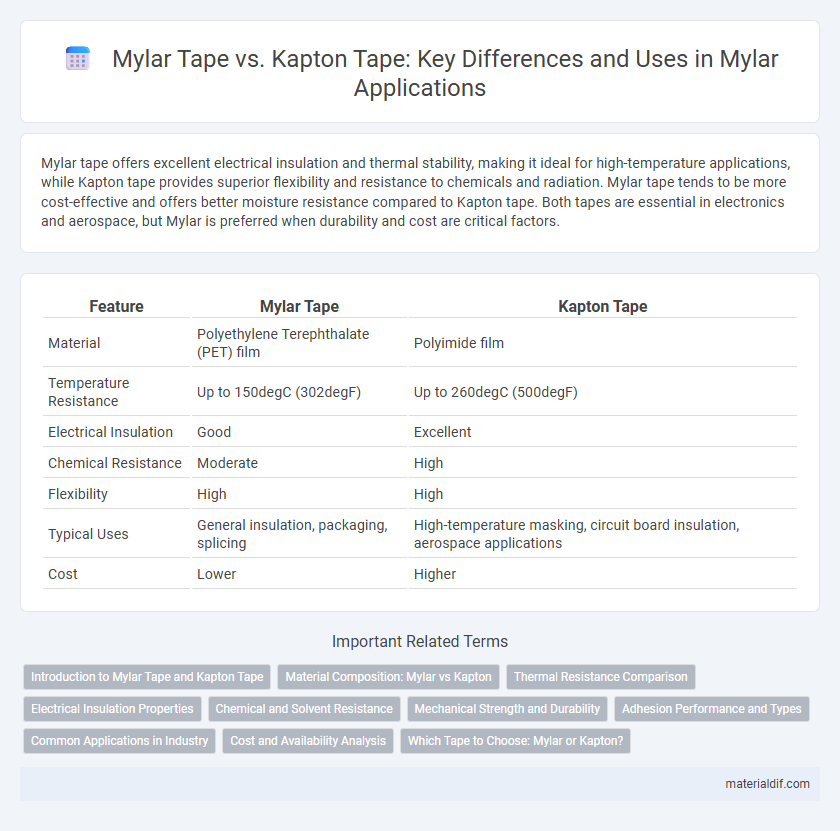

Table of Comparison

| Feature | Mylar Tape | Kapton Tape |

|---|---|---|

| Material | Polyethylene Terephthalate (PET) film | Polyimide film |

| Temperature Resistance | Up to 150degC (302degF) | Up to 260degC (500degF) |

| Electrical Insulation | Good | Excellent |

| Chemical Resistance | Moderate | High |

| Flexibility | High | High |

| Typical Uses | General insulation, packaging, splicing | High-temperature masking, circuit board insulation, aerospace applications |

| Cost | Lower | Higher |

Introduction to Mylar Tape and Kapton Tape

Mylar tape, made from biaxially-oriented polyethylene terephthalate (PET), offers excellent tensile strength, chemical resistance, and electrical insulation, making it ideal for applications requiring durability and heat resistance up to 150degC. Kapton tape, composed of polyimide film, withstands higher temperatures up to 260degC and provides exceptional electrical insulation and chemical stability, often used in electronics and aerospace industries. Both tapes serve as crucial materials for insulation and protection, with Mylar tape favored for moderate heat resistance and Kapton tape chosen for extreme thermal environments.

Material Composition: Mylar vs Kapton

Mylar tape is made from biaxially-oriented polyethylene terephthalate (PET), which provides excellent tensile strength, chemical resistance, and dimensional stability. Kapton tape is composed of polyimide film, known for its outstanding heat resistance, electrical insulation properties, and flexibility in extreme temperatures. The choice between Mylar and Kapton tape depends on application requirements, where Mylar excels in mechanical durability and Kapton performs best in high-temperature environments.

Thermal Resistance Comparison

Mylar tape offers strong thermal resistance, typically enduring temperatures up to 150degC, making it suitable for moderate heat applications. Kapton tape excels in high-temperature environments with a thermal resistance range covering -269degC to 400degC, ideal for extreme heat insulation and electronic masking. The superior thermal stability of Kapton tape outperforms Mylar tape in demanding industrial and aerospace settings where consistent performance at elevated temperatures is critical.

Electrical Insulation Properties

Mylar tape offers excellent electrical insulation properties with high dielectric strength and resistance to moisture, making it suitable for general electrical applications. Kapton tape provides superior electrical insulation under extreme temperatures and chemical exposure due to its polyimide base, maintaining stability in harsh environments. Both tapes deliver reliable insulation, but Kapton tape is preferred for high-temperature and precision electrical insulation needs.

Chemical and Solvent Resistance

Mylar tape offers excellent chemical resistance, maintaining integrity against solvents, oils, and alkalis, making it highly suitable for industrial and electrical insulation applications. Kapton tape, composed of polyimide film, withstands extreme temperatures but has moderate resistance to certain solvents like ketones and esters, which can degrade its adhesive properties. Choosing Mylar tape ensures superior stability and durability in environments with frequent chemical exposure compared to Kapton tape.

Mechanical Strength and Durability

Mylar tape offers superior mechanical strength and durability compared to Kapton tape, making it ideal for high-stress applications requiring resistance to tearing and abrasion. Its polyester base material withstands stretching and impact better, maintaining integrity under prolonged mechanical strain. Kapton tape, while heat-resistant, generally exhibits lower tensile strength and durability, limiting its use in environments subject to frequent physical wear.

Adhesion Performance and Types

Mylar tape offers superior adhesion performance on smooth and low-energy surfaces, making it ideal for electrical insulation and surface protection applications, while Kapton tape provides excellent adhesion under extreme temperatures and chemical exposures, favored in high-temperature masking and circuit board manufacturing. Mylar tape typically comes in PET film variants coated with acrylic or rubber adhesives, whereas Kapton tape is made from polyimide film with silicone or rubber adhesives designed for durability and heat resistance. Choosing between these tapes depends on specific adhesion needs and environmental conditions, with Mylar excelling in general-use adhesion and Kapton specialized for thermal and chemical stability.

Common Applications in Industry

Mylar tape is widely used for electrical insulation, packaging, and surface protection in the electronics, automotive, and aerospace industries due to its high tensile strength and resistance to moisture and chemicals. Kapton tape excels in applications requiring thermal resistance, such as circuit board assembly, 3D printing, and high-temperature masking in manufacturing processes. Both tapes provide excellent dielectric properties but differ mainly in temperature tolerance and flexibility, influencing their industrial usage.

Cost and Availability Analysis

Mylar tape typically costs less than Kapton tape, making it a more budget-friendly choice for applications requiring electrical insulation or heat resistance. Kapton tape, although more expensive, offers superior thermal stability and chemical resistance, which justifies its higher price in specialized industrial uses. Availability of Mylar tape is generally higher in retail and online markets due to its broader range of applications, while Kapton tape is often found in specialized suppliers serving aerospace and electronics industries.

Which Tape to Choose: Mylar or Kapton?

Mylar tape offers excellent tensile strength, electrical insulation, and resistance to moisture, making it ideal for applications requiring durability and dimensional stability. Kapton tape excels in high-temperature environments due to its polyimide film, providing superior heat resistance up to 400degC and chemical stability. Choose Mylar tape for general electrical insulation and moisture protection, while Kapton tape is best suited for high-temperature processing and electronics manufacturing.

Mylar Tape vs Kapton Tape Infographic

materialdif.com

materialdif.com