Heat-sealable Mylar offers superior convenience and durability by allowing airtight, moisture-resistant packaging that preserves pet food freshness longer than non-heat-sealable Mylar. Non-heat-sealable Mylar lacks this sealing capability, often requiring additional materials or methods, which can compromise the integrity of the pet food's protection. Choosing heat-sealable Mylar ensures a secure, tamper-evident closure, enhancing shelf life and maintaining product quality for pets.

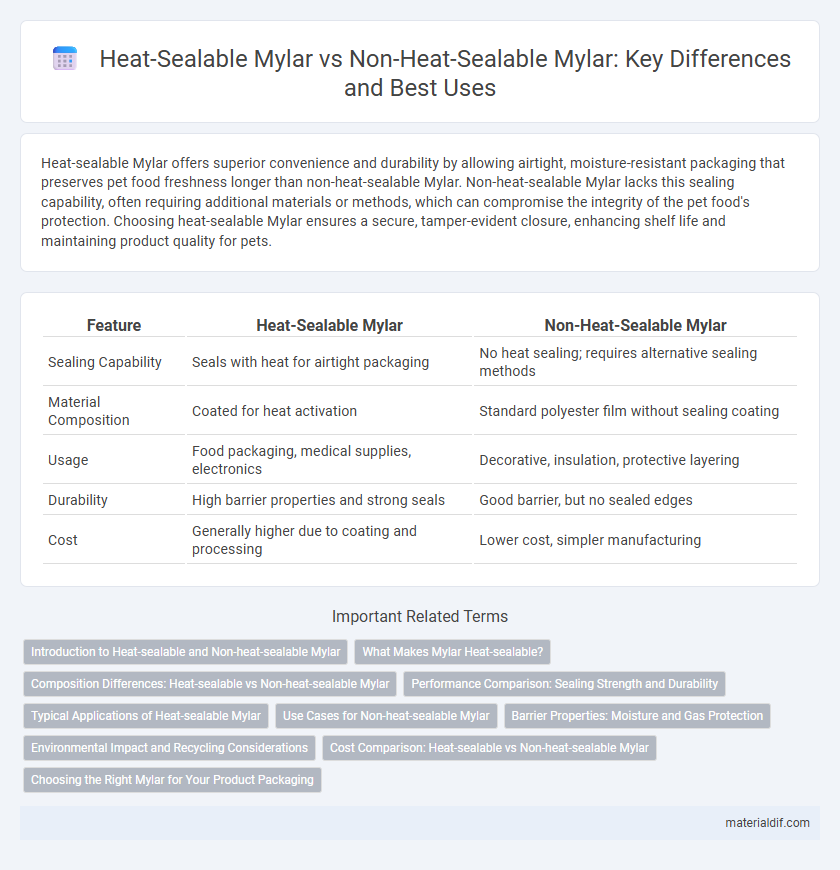

Table of Comparison

| Feature | Heat-Sealable Mylar | Non-Heat-Sealable Mylar |

|---|---|---|

| Sealing Capability | Seals with heat for airtight packaging | No heat sealing; requires alternative sealing methods |

| Material Composition | Coated for heat activation | Standard polyester film without sealing coating |

| Usage | Food packaging, medical supplies, electronics | Decorative, insulation, protective layering |

| Durability | High barrier properties and strong seals | Good barrier, but no sealed edges |

| Cost | Generally higher due to coating and processing | Lower cost, simpler manufacturing |

Introduction to Heat-sealable and Non-heat-sealable Mylar

Heat-sealable Mylar is a polyester film coated with a heat-activated adhesive layer, enabling it to bond securely when exposed to heat and pressure, making it ideal for packaging applications requiring airtight seals. Non-heat-sealable Mylar lacks this adhesive coating, offering superior clarity, durability, and chemical resistance but cannot form sealed joints through heat. Understanding the distinction helps in selecting the appropriate Mylar type for applications ranging from food packaging to insulation.

What Makes Mylar Heat-sealable?

Mylar becomes heat-sealable through the application of a specialized polyethylene coating that melts at a specific temperature, allowing the layers to bond when heat and pressure are applied. This coating creates a thermoplastic surface that facilitates efficient sealing without compromising the film's inherent strength, clarity, or barrier properties. Non-heat-sealable Mylar lacks this polyethylene layer, making it unsuitable for heat-sealing but ideal for applications requiring high tensile strength and durability without the need for sealing.

Composition Differences: Heat-sealable vs Non-heat-sealable Mylar

Heat-sealable Mylar is coated with a thermoplastic layer, typically polyethylene or a similar polymer, allowing it to bond securely when heat is applied. Non-heat-sealable Mylar consists primarily of pure polyethylene terephthalate (PET) without any additional coatings, which prevents it from melting or bonding under heat. These compositional differences determine their applications, with heat-sealable Mylar preferred for packaging and sealing needs, while non-heat-sealable Mylar is used for insulation and protective barriers.

Performance Comparison: Sealing Strength and Durability

Heat-sealable Mylar offers superior sealing strength due to its specially coated surface that bonds securely under heat, ensuring airtight and moisture-resistant packaging. Non-heat-sealable Mylar lacks this coating, resulting in weaker seals that are prone to leakage and reduced protection over time. Durability in heat-sealable Mylar outperforms non-heat-sealable varieties by maintaining integrity under stress and environmental exposure, making it ideal for long-term storage applications.

Typical Applications of Heat-sealable Mylar

Heat-sealable Mylar is widely used in food packaging, medical sterile barriers, and electronic component protection due to its ability to create airtight and moisture-resistant seals. This form of Mylar enables reliable containment and shelf-life extension for perishable goods and pharmaceuticals. Its robust sealing properties also make it integral in flexible packaging solutions requiring tamper-evidence and contamination prevention.

Use Cases for Non-heat-sealable Mylar

Non-heat-sealable Mylar is commonly used in applications requiring durable, moisture-resistant barriers without the need for sealing, such as insulation, reflective insulation panels, and emergency blankets. It excels in packaging fragile electronics or documents where protection from moisture and static is essential but sealing is managed by other methods. This type of Mylar also serves effectively in decorative purposes, promotional materials, and reinforcement layers in composite materials.

Barrier Properties: Moisture and Gas Protection

Heat-sealable Mylar offers superior barrier properties by creating airtight seals that effectively prevent moisture and gas penetration, ensuring enhanced preservation and protection. Non-heat-sealable Mylar lacks this sealing capability, making it less effective in maintaining an impermeable barrier against environmental factors. This distinction significantly impacts the longevity and integrity of products requiring moisture and gas protection.

Environmental Impact and Recycling Considerations

Heat-sealable Mylar incorporates a thermoplastic coating that allows for airtight sealing, which enhances product preservation but can complicate recycling due to mixed material layers, often requiring specialized processes to separate polymers. Non-heat-sealable Mylar, typically a pure polyester film, offers better recyclability as it can be more easily processed by PET recycling streams, reducing contamination and environmental impact. Choosing non-heat-sealable Mylar supports more sustainable waste management practices and lowers the ecological footprint associated with film disposal.

Cost Comparison: Heat-sealable vs Non-heat-sealable Mylar

Heat-sealable Mylar typically incurs higher costs due to its specialized coating that enables sealing through heat activation, increasing production complexity and material expense. Non-heat-sealable Mylar is generally more economical, lacking the additional sealing layer, making it suitable for applications where airtight or tamper-evident seals are unnecessary. Cost efficiency between the two depends heavily on packaging requirements, with heat-sealable variants justifying their price through enhanced sealing performance and product protection.

Choosing the Right Mylar for Your Product Packaging

Heat-sealable Mylar offers a convenient and reliable method for sealing packaging, ensuring airtight protection and extended shelf life for perishable goods. Non-heat-sealable Mylar, while providing excellent barrier properties against moisture and oxygen, requires alternative sealing methods such as adhesives or mechanical seals. Selecting the right Mylar depends on product sensitivity, packaging equipment, and desired shelf life, with heat-sealable variants typically preferred for food, pharmaceuticals, and cosmetics due to their enhanced sealing capabilities.

Heat-sealable Mylar vs Non-heat-sealable Mylar Infographic

materialdif.com

materialdif.com