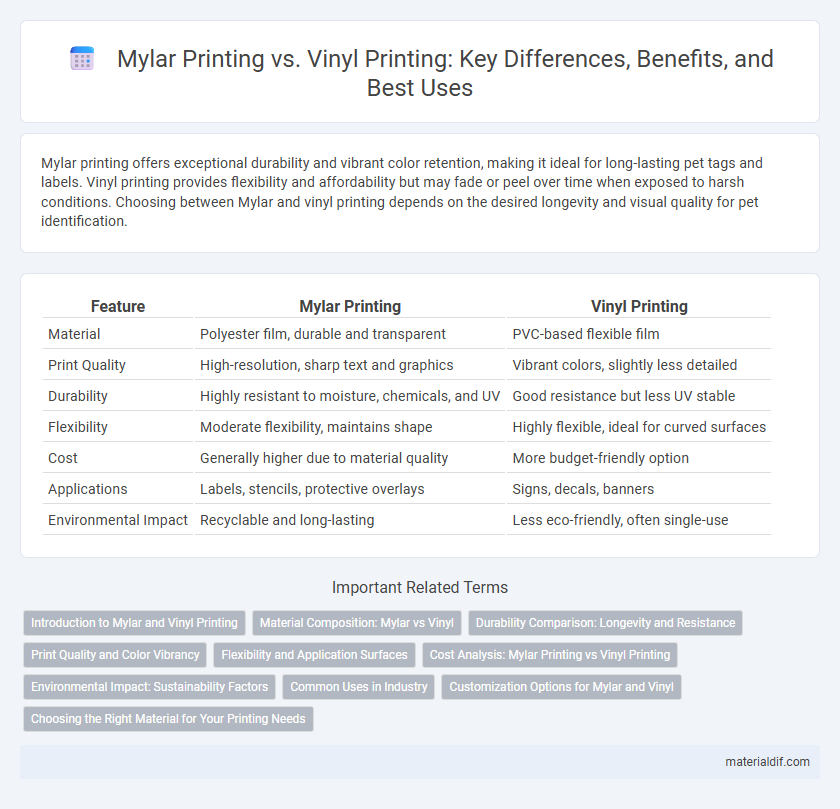

Mylar printing offers exceptional durability and vibrant color retention, making it ideal for long-lasting pet tags and labels. Vinyl printing provides flexibility and affordability but may fade or peel over time when exposed to harsh conditions. Choosing between Mylar and vinyl printing depends on the desired longevity and visual quality for pet identification.

Table of Comparison

| Feature | Mylar Printing | Vinyl Printing |

|---|---|---|

| Material | Polyester film, durable and transparent | PVC-based flexible film |

| Print Quality | High-resolution, sharp text and graphics | Vibrant colors, slightly less detailed |

| Durability | Highly resistant to moisture, chemicals, and UV | Good resistance but less UV stable |

| Flexibility | Moderate flexibility, maintains shape | Highly flexible, ideal for curved surfaces |

| Cost | Generally higher due to material quality | More budget-friendly option |

| Applications | Labels, stencils, protective overlays | Signs, decals, banners |

| Environmental Impact | Recyclable and long-lasting | Less eco-friendly, often single-use |

Introduction to Mylar and Vinyl Printing

Mylar printing utilizes polyester film known for its durability, clarity, and resistance to moisture and chemicals, making it ideal for high-quality, long-lasting graphics. Vinyl printing employs flexible polyvinyl chloride material, praised for its versatility, weather resistance, and vibrant color reproduction, commonly used for outdoor signage and vehicle wraps. Both methods serve distinct applications, with Mylar offering superior transparency and rigidity, while vinyl excels in flexibility and adhesive properties.

Material Composition: Mylar vs Vinyl

Mylar printing utilizes a polyester film known for its flexibility, durability, and resistance to moisture and chemicals, making it ideal for high-quality, long-lasting prints. Vinyl printing employs a polyvinyl chloride (PVC) base, offering strong adhesion and weather resistance but tends to be thicker and less transparent than Mylar. The distinct material compositions influence their performance in applications, with Mylar favored for clarity and precision, while vinyl excels in outdoor durability and versatility.

Durability Comparison: Longevity and Resistance

Mylar printing offers superior durability with enhanced resistance to moisture, tearing, and UV exposure, making it ideal for long-term outdoor applications. Vinyl printing, while durable, typically exhibits shorter lifespan under harsh environmental conditions due to its lower resistance to fading and cracking. Mylar's longevity advantage stems from its polyester base, which maintains print quality and structural integrity far longer than standard vinyl materials.

Print Quality and Color Vibrancy

Mylar printing delivers superior print quality with sharper details and higher resolution compared to vinyl printing, making it ideal for intricate designs. The color vibrancy on Mylar is more intense and long-lasting, thanks to its smooth, reflective surface that enhances ink absorption and brightness. Vinyl printing, while durable, often results in flatter colors and less precision, which can impact the overall visual appeal of graphics.

Flexibility and Application Surfaces

Mylar printing offers superior flexibility compared to vinyl printing, making it ideal for applications on curved or irregular surfaces such as fabric, glass, and plastic. Mylar's lightweight and durable polyester film adapts easily to dynamic environments, allowing for high-resolution graphics on sportswear, banners, and electronic displays. Vinyl printing, while durable, is generally stiffer and better suited for flat or slightly curved surfaces like walls, vehicles, and signage.

Cost Analysis: Mylar Printing vs Vinyl Printing

Mylar printing generally incurs higher upfront costs due to specialized materials and equipment, but it offers greater durability and resistance to environmental factors, potentially reducing long-term replacement expenses. Vinyl printing tends to be more cost-effective initially, making it suitable for short-term or budget-conscious projects, though it may require more frequent replacements. When analyzing total cost of ownership, Mylar's longevity often offsets initial investment, making it a viable option for high-wear applications.

Environmental Impact: Sustainability Factors

Mylar printing uses polyethylene terephthalate (PET), a recyclable plastic that reduces waste when properly processed, whereas vinyl printing relies on polyvinyl chloride (PVC), which poses significant environmental hazards due to toxic chemical release during production and disposal. Mylar's durability and recyclability contribute to lower ecological footprints and reduced landfill accumulation compared to the non-biodegradable nature of vinyl prints. Choosing Mylar printing supports sustainability by minimizing harmful emissions and enhancing material reuse in graphic and packaging industries.

Common Uses in Industry

Mylar printing is commonly used in industries requiring durable, clear, and heat-resistant materials such as graphic arts, electronics, and signage, whereas vinyl printing is preferred for flexible, weather-resistant applications like vehicle wraps, banners, and decals. Mylar's resistance to UV light and moisture makes it ideal for long-lasting labels and protective overlays, while vinyl's adhesive properties enable versatile use on curved or textured surfaces. Both printing methods serve marketing, industrial labeling, and decorative purposes with distinct material advantages tailored to specific environmental demands.

Customization Options for Mylar and Vinyl

Mylar printing offers extensive customization options including vibrant color reproduction, high-resolution graphics, and the ability to incorporate metallic and reflective finishes, making it ideal for eye-catching designs. Vinyl printing provides flexibility with various textures, finishes, and durability levels, suitable for outdoor applications and signage requiring weather resistance. Both materials support custom shapes and sizes, but Mylar excels in detailed, glossy aesthetics while vinyl prioritizes robustness and versatility.

Choosing the Right Material for Your Printing Needs

Mylar printing offers superior durability, water resistance, and vibrant color retention, making it ideal for outdoor banners and long-term signage. Vinyl printing provides flexibility, cost-effectiveness, and ease of application, suited for temporary displays and vehicle wraps. Selecting between Mylar and vinyl depends on the project's exposure to elements, desired lifespan, and budget constraints.

Mylar Printing vs Vinyl Printing Infographic

materialdif.com

materialdif.com