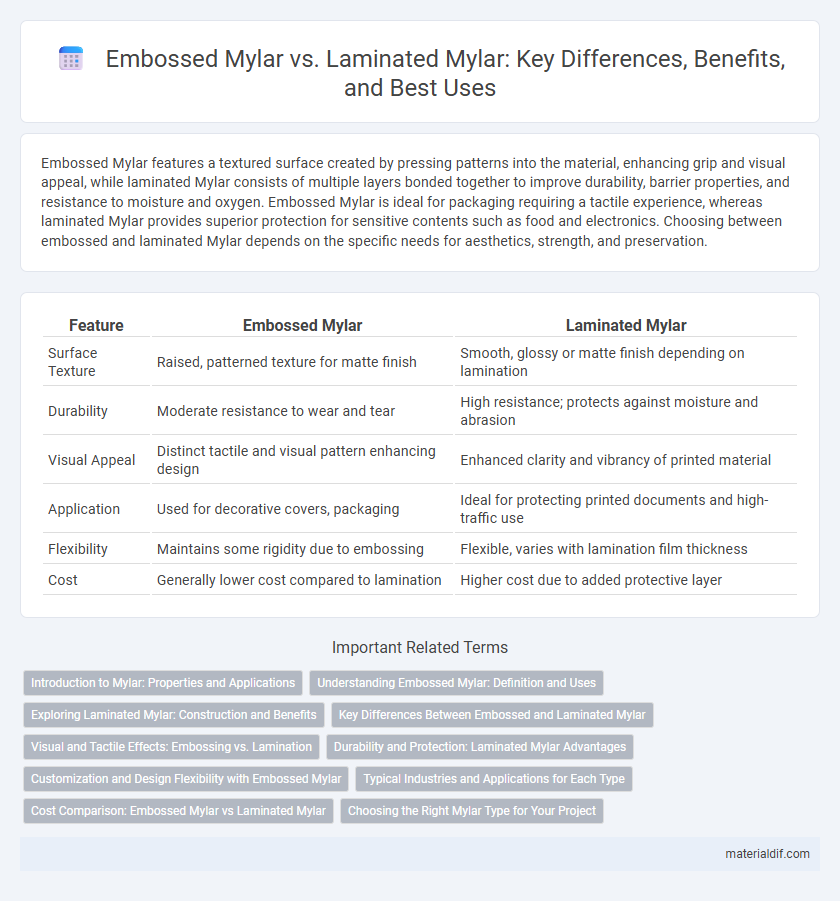

Embossed Mylar features a textured surface created by pressing patterns into the material, enhancing grip and visual appeal, while laminated Mylar consists of multiple layers bonded together to improve durability, barrier properties, and resistance to moisture and oxygen. Embossed Mylar is ideal for packaging requiring a tactile experience, whereas laminated Mylar provides superior protection for sensitive contents such as food and electronics. Choosing between embossed and laminated Mylar depends on the specific needs for aesthetics, strength, and preservation.

Table of Comparison

| Feature | Embossed Mylar | Laminated Mylar |

|---|---|---|

| Surface Texture | Raised, patterned texture for matte finish | Smooth, glossy or matte finish depending on lamination |

| Durability | Moderate resistance to wear and tear | High resistance; protects against moisture and abrasion |

| Visual Appeal | Distinct tactile and visual pattern enhancing design | Enhanced clarity and vibrancy of printed material |

| Application | Used for decorative covers, packaging | Ideal for protecting printed documents and high-traffic use |

| Flexibility | Maintains some rigidity due to embossing | Flexible, varies with lamination film thickness |

| Cost | Generally lower cost compared to lamination | Higher cost due to added protective layer |

Introduction to Mylar: Properties and Applications

Mylar is a polyester film known for its high tensile strength, chemical stability, and excellent thermal and electrical insulation properties, making it ideal for various industrial and packaging applications. Embossed Mylar features textured patterns that enhance grip and diffusion, frequently used in decorative and anti-slip products. Laminated Mylar consists of multiple layers bonded to increase durability, barrier protection, and resistance to moisture, often applied in food packaging and insulation materials.

Understanding Embossed Mylar: Definition and Uses

Embossed Mylar is a type of polyester film characterized by a textured surface created through a heat and pressure process, enhancing grip and light diffusion. Commonly used in packaging, decorative applications, and insulation, embossed Mylar improves product appeal and functional performance by reducing glare and providing a tactile finish. Unlike laminated Mylar, which involves bonding multiple layers for added strength or barrier properties, embossed Mylar's primary benefit lies in its unique surface texture and aesthetic versatility.

Exploring Laminated Mylar: Construction and Benefits

Laminated Mylar consists of multiple layers bonded together, enhancing durability, moisture resistance, and dimensional stability compared to Embossed Mylar, which features a textured surface on a single layer. The lamination process improves barrier properties against oxygen and contaminants, making laminated Mylar ideal for packaging sensitive products like food and pharmaceuticals. Its enhanced strength and flexibility also contribute to superior performance in insulation and protective applications.

Key Differences Between Embossed and Laminated Mylar

Embossed Mylar features a textured surface created by pressing patterns into the material, enhancing grip and light diffusion, while laminated Mylar consists of multiple bonded layers providing increased durability, moisture resistance, and clarity. Embossing alters the physical structure, improving tactile and visual effects, whereas lamination adds protective barriers without changing the surface texture. These key differences impact their suitability in applications such as packaging, insulation, and decorative finishes.

Visual and Tactile Effects: Embossing vs. Lamination

Embossed Mylar creates raised patterns that add depth and tactile texture, enhancing visual appeal through shadows and highlights. Laminated Mylar offers a smooth, glossy or matte finish that protects the surface while providing a sleek, uniform look. The choice between embossing and lamination depends on whether a three-dimensional feel or a polished, durable coating is desired.

Durability and Protection: Laminated Mylar Advantages

Laminated Mylar offers superior durability and enhanced protection compared to Embossed Mylar due to its additional laminated layer, which increases resistance to moisture, tearing, and UV damage. The lamination process reinforces the material's strength, making it ideal for long-term storage and safeguarding sensitive items. This added protection ensures Laminated Mylar maintains structural integrity under harsh environmental conditions better than Embossed Mylar.

Customization and Design Flexibility with Embossed Mylar

Embossed Mylar offers superior customization and design flexibility compared to laminated Mylar, allowing for intricate textures and raised patterns that enhance visual appeal and tactile experience. This technique enables precise detailing and unique finishes, ideal for branding and packaging that demand a distinct look and feel. In contrast, laminated Mylar primarily provides a smooth, protective surface with limited textural options, restricting creative expression.

Typical Industries and Applications for Each Type

Embossed Mylar is commonly used in the packaging industry for decorative labels, gift wraps, and security seals due to its textured surface that enhances grip and visual appeal. Laminated Mylar finds extensive application in electronics and aerospace sectors, offering superior moisture resistance and dimensional stability for flexible circuits and protective overlays. Both types serve the printing industry, but embossed variants excel in tactile branding, while laminated films prioritize durability and chemical resistance.

Cost Comparison: Embossed Mylar vs Laminated Mylar

Embossed Mylar generally incurs lower production costs due to simpler manufacturing processes and reduced material usage compared to Laminated Mylar, which involves multiple layers and adhesives that raise expenses. The added durability and enhanced barrier properties of Laminated Mylar justify its higher price point for applications requiring superior protection. Cost-effectiveness depends on the specific use case, with Embossed Mylar favored for budget-conscious projects and Laminated Mylar reserved for premium packaging needs.

Choosing the Right Mylar Type for Your Project

Embossed Mylar offers a textured surface that enhances grip and diffusion, making it ideal for projects requiring visual appeal and tactile feedback, such as decorative packaging or signage. Laminated Mylar provides a smooth, protective layer that increases durability, moisture resistance, and longevity, suitable for applications like insulation, posters, or photo preservation. Selecting between embossed and laminated Mylar depends on your project's need for surface texture versus protective qualities, ensuring optimal performance and aesthetic outcome.

Embossed Mylar vs Laminated Mylar Infographic

materialdif.com

materialdif.com