Mylar reflective film offers lightweight, flexible, and shatterproof properties compared to the rigid and fragile nature of silvered glass, making it ideal for applications requiring durability and ease of installation. The high reflectivity of Mylar enhances light efficiency and energy savings, while silvered glass provides a more traditional aesthetic but at the expense of increased weight and fragility. Mylar's resistance to moisture and breakage makes it a preferred choice in environments where safety and longevity are critical.

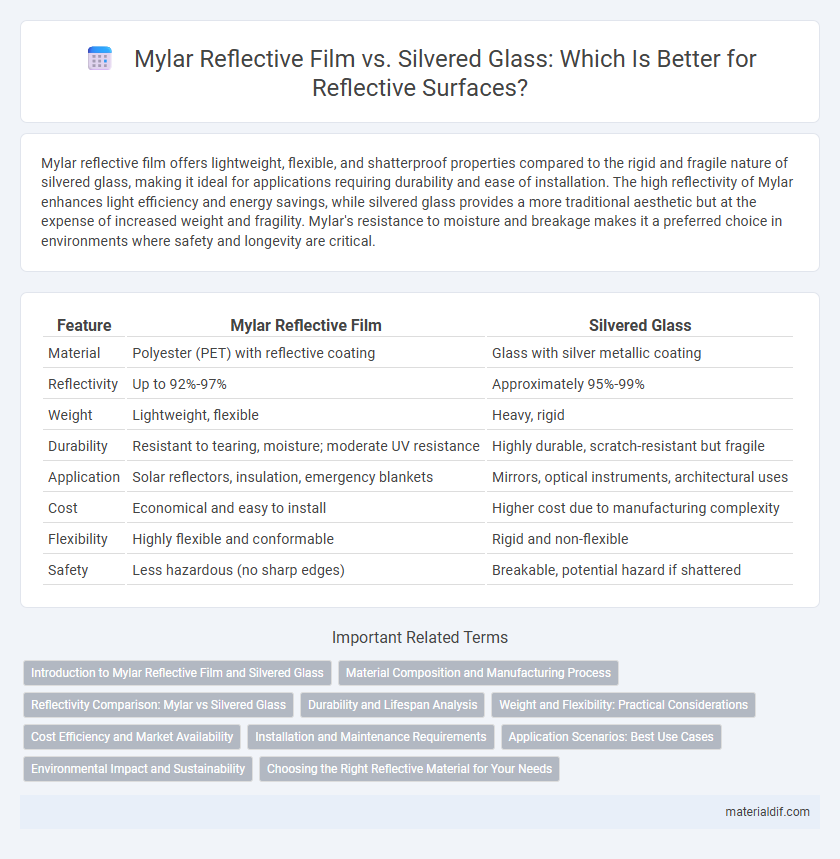

Table of Comparison

| Feature | Mylar Reflective Film | Silvered Glass |

|---|---|---|

| Material | Polyester (PET) with reflective coating | Glass with silver metallic coating |

| Reflectivity | Up to 92%-97% | Approximately 95%-99% |

| Weight | Lightweight, flexible | Heavy, rigid |

| Durability | Resistant to tearing, moisture; moderate UV resistance | Highly durable, scratch-resistant but fragile |

| Application | Solar reflectors, insulation, emergency blankets | Mirrors, optical instruments, architectural uses |

| Cost | Economical and easy to install | Higher cost due to manufacturing complexity |

| Flexibility | Highly flexible and conformable | Rigid and non-flexible |

| Safety | Less hazardous (no sharp edges) | Breakable, potential hazard if shattered |

Introduction to Mylar Reflective Film and Silvered Glass

Mylar reflective film is a polyester film coated with a thin layer of metal, typically aluminum, offering high reflectivity and lightweight flexibility for insulation and lighting applications. Silvered glass features a silver coating on glass, providing durable, high-reflectance surfaces commonly used in mirrors and decorative finishes. Both materials excel in reflecting light but differ significantly in weight, flexibility, and application versatility.

Material Composition and Manufacturing Process

Mylar reflective film is made from stretched polyethylene terephthalate (PET) coated with a thin layer of aluminum, offering lightweight flexibility and durability, while silvered glass consists of a glass substrate with a reflective silver coating applied through a chemical or vacuum deposition process. Mylar's manufacturing involves biaxial orientation and metallization, resulting in a high tensile strength film with reflective properties, whereas silvered glass undergoes glass blowing or molding followed by silver coating and protective layering. The PET base in Mylar provides impact resistance and ease of installation, contrasting with the rigid and fragile nature of silvered glass.

Reflectivity Comparison: Mylar vs Silvered Glass

Mylar reflective film typically offers reflectivity rates between 80% to 95%, depending on its thickness and surface finish, while silvered glass can achieve reflectivity levels exceeding 95% due to its metallic silver coating. Mylar is lightweight, flexible, and resistant to shattering, making it ideal for applications requiring durability and ease of installation. Silvered glass, although heavier and fragile, provides superior optical clarity and long-term reflectivity stability in controlled environments.

Durability and Lifespan Analysis

Mylar reflective film offers superior durability compared to silvered glass, as it is resistant to shattering and corrosion, making it ideal for environments with varying temperatures and humidity. Unlike silvered glass, which can degrade over time due to oxidation and physical impact, Mylar maintains its reflective properties for years without significant wear. The lifespan of Mylar reflective film often exceeds a decade under proper conditions, surpassing the typical 5-10 year lifespan of silvered glass mirrors.

Weight and Flexibility: Practical Considerations

Mylar reflective film weighs significantly less than silvered glass, making it ideal for applications where reducing overall weight is critical, such as portable solar reflectors and insulated packaging. Its flexibility allows it to conform to curved and irregular surfaces, unlike rigid silvered glass, which can be fragile and prone to breakage. These properties make Mylar a practical choice for lightweight, durable, and adaptable reflective solutions.

Cost Efficiency and Market Availability

Mylar reflective film offers significant cost efficiency compared to silvered glass due to its lower manufacturing and installation expenses, making it an attractive option for budget-conscious projects. The lightweight nature of Mylar reduces shipping costs and eases handling requirements, further enhancing its market viability. Widely available through multiple distributors, Mylar reflective film ensures easier access and faster procurement than silvered glass, which often involves specialized suppliers and higher lead times.

Installation and Maintenance Requirements

Mylar reflective film offers a lightweight and flexible installation process, adhering easily to various surfaces with minimal tools, while silvered glass requires professional handling and heavier mounting systems due to its rigid and fragile nature. Maintenance for Mylar film involves occasional cleaning with gentle, non-abrasive materials to retain reflectivity, whereas silvered glass demands regular inspection for scratches and potential delamination, often necessitating specialized cleaning agents. The cost-effectiveness of Mylar's installation and upkeep makes it a preferred choice for applications requiring quick setup and low maintenance compared to the more delicate and labor-intensive care silvered glass entails.

Application Scenarios: Best Use Cases

Mylar reflective film excels in applications requiring lightweight, flexible, and durable materials such as emergency blankets, grow rooms, and solar cookers, where high reflectivity and portability are crucial. Silvered glass is ideal for architectural mirrors, solar panels, and decorative uses demanding rigidity, superior optical clarity, and enhanced durability. Choosing between Mylar and silvered glass depends on whether the environment prioritizes flexibility and impact resistance or structural stability and precision reflection.

Environmental Impact and Sustainability

Mylar reflective film offers a lower environmental impact compared to silvered glass due to its lightweight composition and reduced energy consumption during manufacturing. Unlike silvered glass, which requires energy-intensive processes and contains heavy metals like silver that pose recycling challenges, Mylar is made from polyethylene terephthalate (PET), a material that is widely recyclable and requires less raw material extraction. The sustainability of Mylar reflective film supports eco-friendly applications by minimizing waste and facilitating easier end-of-life recycling, making it a more environmentally responsible choice for reflective solutions.

Choosing the Right Reflective Material for Your Needs

Mylar reflective film offers lightweight, flexible, and cost-effective solutions with high reflectivity, making it ideal for applications requiring easy installation and durability. Silvered glass provides superior optical clarity and long-term resistance to environmental factors, suitable for high-precision and architectural uses. Selecting between Mylar and silvered glass depends on factors like budget, required reflectivity, installation environment, and mechanical strength needs.

Mylar Reflective Film vs Silvered Glass Infographic

materialdif.com

materialdif.com