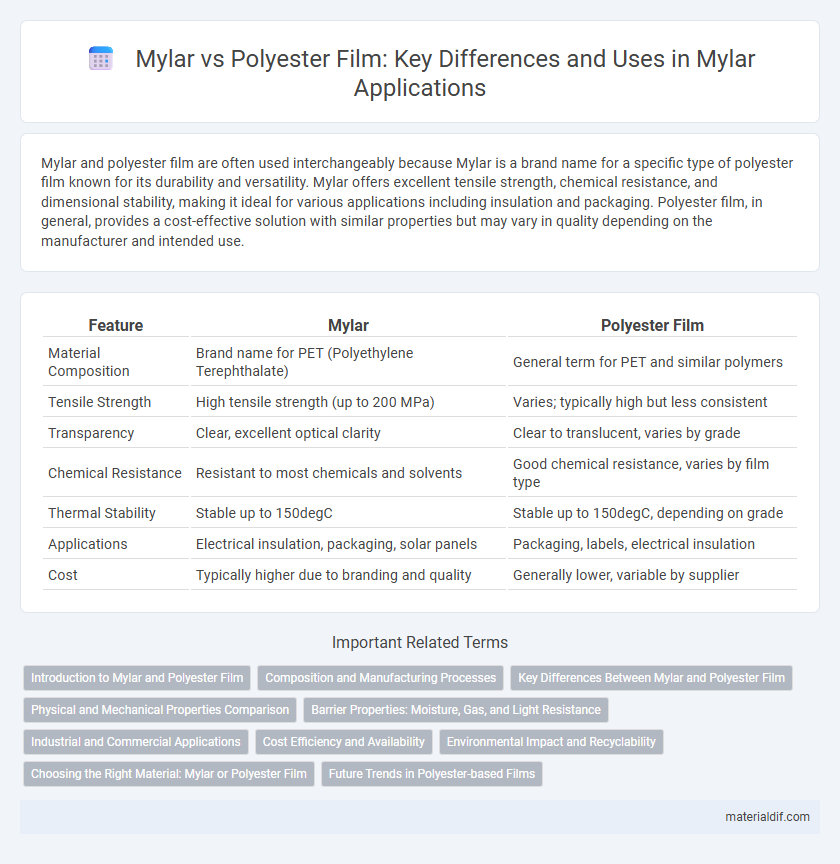

Mylar and polyester film are often used interchangeably because Mylar is a brand name for a specific type of polyester film known for its durability and versatility. Mylar offers excellent tensile strength, chemical resistance, and dimensional stability, making it ideal for various applications including insulation and packaging. Polyester film, in general, provides a cost-effective solution with similar properties but may vary in quality depending on the manufacturer and intended use.

Table of Comparison

| Feature | Mylar | Polyester Film |

|---|---|---|

| Material Composition | Brand name for PET (Polyethylene Terephthalate) | General term for PET and similar polymers |

| Tensile Strength | High tensile strength (up to 200 MPa) | Varies; typically high but less consistent |

| Transparency | Clear, excellent optical clarity | Clear to translucent, varies by grade |

| Chemical Resistance | Resistant to most chemicals and solvents | Good chemical resistance, varies by film type |

| Thermal Stability | Stable up to 150degC | Stable up to 150degC, depending on grade |

| Applications | Electrical insulation, packaging, solar panels | Packaging, labels, electrical insulation |

| Cost | Typically higher due to branding and quality | Generally lower, variable by supplier |

Introduction to Mylar and Polyester Film

Mylar, a brand name for biaxially oriented polyethylene terephthalate (BoPET) film, offers exceptional strength, chemical stability, and electrical insulation. Polyester film, a broader category including Mylar, provides versatile applications in packaging, insulation, and printing due to its durability and clarity. Both materials share similar polyethylene terephthalate bases but differ in coating treatments and brand-specific properties, affecting their performance and cost.

Composition and Manufacturing Processes

Mylar is a trademarked brand of biaxially-oriented polyethylene terephthalate (BoPET) film, renowned for its exceptional strength, chemical stability, and insulating properties. Polyester film, a broader category that includes Mylar, is produced through extrusion or casting processes, followed by biaxial orientation to enhance mechanical performance. The manufacturing of Mylar involves precise control over the stretching and heat-setting stages, resulting in a highly uniform film with superior dimensional stability compared to generic polyester films.

Key Differences Between Mylar and Polyester Film

Mylar is a brand name for a type of polyester film known for its superior tensile strength, chemical stability, and electrical insulation properties compared to generic polyester films. Key differences between Mylar and standard polyester film include Mylar's enhanced dimensional stability and resistance to moisture, heat, and UV radiation, making it ideal for specialized industrial applications. While all Mylar films are polyester-based, Mylar specifically meets stringent quality standards and often contains proprietary formulations that improve performance in demanding environments.

Physical and Mechanical Properties Comparison

Mylar, a brand name for biaxially-oriented polyethylene terephthalate (BoPET), exhibits superior tensile strength and dimensional stability compared to standard polyester film, making it more resistant to stretching and shrinking under stress. The physical properties such as higher melting point around 260degC and lower water absorption rate enhance Mylar's durability in extreme environments. Its mechanical properties, including excellent impact resistance and flexibility, outperform generic polyester films, making Mylar ideal for applications demanding long-term reliability and strength.

Barrier Properties: Moisture, Gas, and Light Resistance

Mylar, a brand of biaxially-oriented polyethylene terephthalate (BoPET), offers superior barrier properties compared to standard polyester films, particularly in moisture, gas, and light resistance. Its dense molecular structure significantly reduces water vapor transmission rate (WVTR) and oxygen transmission rate (OTR), making it ideal for packaging that requires extended shelf life and protection against environmental factors. Enhanced UV light resistance in Mylar further prevents degradation and preserves the integrity of sensitive contents.

Industrial and Commercial Applications

Mylar, a brand name for biaxially-oriented polyethylene terephthalate (BoPET), offers superior tensile strength, chemical stability, and dimensional stability compared to generic polyester films, making it ideal for demanding industrial and commercial applications such as insulation, capacitors, and graphic arts. Its enhanced clarity, reflectivity, and barrier properties ensure reliable performance in packaging, electronics, and thermal insulation, surpassing standard polyester films in durability and heat resistance. Industries prioritize Mylar for applications requiring long-term durability, resistance to environmental factors, and precise material consistency.

Cost Efficiency and Availability

Mylar, a brand of polyester film, often offers competitive cost efficiency due to its widespread production and consistent quality, making it a preferred choice for bulk purchases in industrial applications. Polyester films, while similar in properties, vary in price and availability depending on the manufacturer and specific formulation, which can affect overall project budgets. The extensive global supply chain for Mylar ensures better availability and stable pricing compared to generic polyester films, benefiting long-term procurement strategies.

Environmental Impact and Recyclability

Mylar, a brand of biaxially oriented polyethylene terephthalate (BoPET) film, offers superior recyclability compared to many other polyester films due to its consistent chemical composition and widespread recycling programs. Polyester films, although similar in base material, often vary in additives and coatings that can hinder recycling processes and increase environmental impact. The environmental footprint of Mylar is further reduced by its durability and reusability, minimizing waste and resource consumption over time.

Choosing the Right Material: Mylar or Polyester Film

Mylar, a brand of polyester film, offers superior tensile strength, chemical resistance, and dimensional stability compared to generic polyester films, making it ideal for demanding applications like insulation and electronics. Polyester film provides cost-effective versatility and moderate durability suitable for packaging and graphic arts, where extreme performance is less critical. Selecting between Mylar and standard polyester film depends on factors like mechanical stress, environmental exposure, and budget constraints.

Future Trends in Polyester-based Films

Future trends in polyester-based films emphasize enhanced barrier properties, increased thickness uniformity, and improved thermal stability, positioning Mylar as a leading material for advanced packaging and electronics. Innovations include nanocoating technologies to boost moisture and oxygen resistance, alongside sustainable manufacturing techniques aiming to reduce environmental impact. Continued research targets embedding functional layers for smart packaging, such as sensors or antimicrobial coatings, expanding Mylar's applications in the evolving polyester film market.

Mylar vs Polyester Film Infographic

materialdif.com

materialdif.com