Mylar printing offers superior durability and water resistance compared to polypropylene printing, making it ideal for long-lasting applications. The glossy finish of Mylar enhances color vibrancy and sharpness, resulting in more visually striking prints. Polypropylene printing is generally more cost-effective, but it lacks the resilience and premium appearance that Mylar provides.

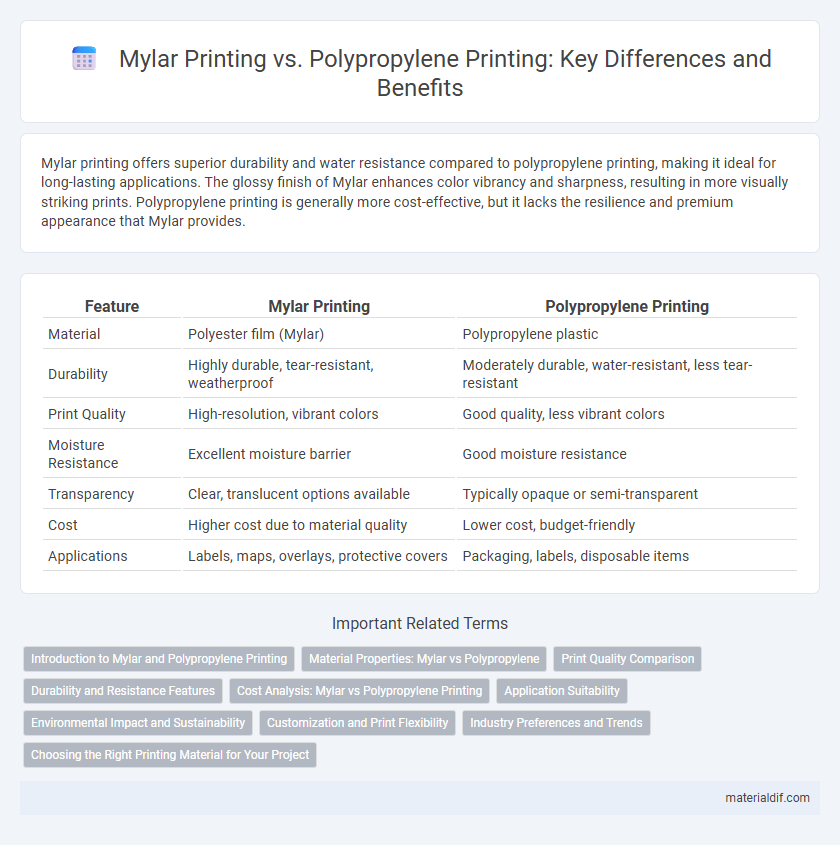

Table of Comparison

| Feature | Mylar Printing | Polypropylene Printing |

|---|---|---|

| Material | Polyester film (Mylar) | Polypropylene plastic |

| Durability | Highly durable, tear-resistant, weatherproof | Moderately durable, water-resistant, less tear-resistant |

| Print Quality | High-resolution, vibrant colors | Good quality, less vibrant colors |

| Moisture Resistance | Excellent moisture barrier | Good moisture resistance |

| Transparency | Clear, translucent options available | Typically opaque or semi-transparent |

| Cost | Higher cost due to material quality | Lower cost, budget-friendly |

| Applications | Labels, maps, overlays, protective covers | Packaging, labels, disposable items |

Introduction to Mylar and Polypropylene Printing

Mylar printing utilizes polyester film known for its excellent durability, dimensional stability, and resistance to moisture and chemicals, making it ideal for long-lasting labels and packaging. Polypropylene printing employs a versatile plastic film characterized by its lightweight nature, good clarity, and cost-effectiveness, often used in flexible packaging and labels requiring moderate durability. Both materials offer unique benefits depending on application requirements, with Mylar providing superior strength and polypropylene excelling in economic and environmental efficiency.

Material Properties: Mylar vs Polypropylene

Mylar excels in dimensional stability and chemical resistance due to its polyester composition, making it highly durable under heat and moisture exposure compared to polypropylene. Polypropylene offers superior flexibility and impact resistance but falls short of Mylar's tensile strength and transparency. These material properties impact printing quality, with Mylar providing sharper image clarity and longer-lasting prints than polypropylene.

Print Quality Comparison

Mylar printing offers superior print quality with enhanced color vibrancy and sharper image resolution due to its smooth and non-porous polyester surface, making it ideal for detailed graphics and high-definition prints. Polypropylene printing, while cost-effective and durable, often results in slightly lower print clarity and color saturation because of its more porous texture that can absorb inks inconsistently. For applications demanding precise, vivid imagery and longevity, Mylar is the preferred substrate over polypropylene.

Durability and Resistance Features

Mylar printing offers superior durability and resistance compared to polypropylene printing due to its polyester base, which provides excellent tensile strength and tear resistance. It demonstrates high resistance to moisture, chemicals, and UV exposure, making it ideal for long-term outdoor applications. Polypropylene printing, while cost-effective and moisture-resistant, generally lacks the same level of abrasion resistance and environmental stability as Mylar.

Cost Analysis: Mylar vs Polypropylene Printing

Mylar printing typically incurs higher material costs compared to polypropylene due to its enhanced durability and resistance to moisture, making it ideal for premium packaging and labels. Polypropylene printing offers a more cost-effective solution with adequate strength for everyday applications, reducing overall production expenses in large-volume projects. Evaluating the trade-offs between Mylar's longevity and polypropylene's affordability is crucial for budget-conscious printing decisions.

Application Suitability

Mylar printing offers superior durability and chemical resistance, making it ideal for outdoor applications, industrial labels, and long-term archival materials. Polypropylene printing provides excellent clarity and flexibility, best suited for food packaging, flexible labeling, and short-to-medium-term product branding. Selecting Mylar is advantageous when moisture resistance and longevity are critical, whereas polypropylene fits applications prioritizing cost-effectiveness and ease of recycling.

Environmental Impact and Sustainability

Mylar printing utilizes biaxially oriented polyethylene terephthalate (BoPET), offering superior durability and recyclability compared to polypropylene, which is a less sturdy polymer with lower recycling rates. Mylar's high resistance to moisture and gases reduces the need for multiple packaging layers, thereby minimizing material waste and environmental footprint. Polypropylene's wider use in single-use packaging results in more landfill accumulation and greater ecological harm due to its slower degradation and limited biodegradability.

Customization and Print Flexibility

Mylar printing offers superior customization and print flexibility due to its smooth, non-porous surface that supports high-resolution graphics and vibrant colors, making it ideal for detailed designs. Polypropylene printing, while cost-effective and durable, has a slightly textured surface that can limit intricate print quality and color vibrancy. The ability of Mylar to withstand various inks and printing techniques enhances its adaptability for customized packaging, labels, and specialty prints compared to polypropylene.

Industry Preferences and Trends

Mylar printing dominates industries requiring high durability and clarity, such as electronics and automotive sectors, due to its superior tensile strength and moisture resistance compared to polypropylene. Polypropylene printing is favored in packaging for cost-efficiency and flexibility, especially in food and consumer goods markets where lightweight materials are critical. Industry trends show a growing preference for Mylar in technical applications, driven by advancements in barrier properties and environmental sustainability considerations.

Choosing the Right Printing Material for Your Project

Mylar printing offers superior durability, chemical resistance, and a glossy finish, making it ideal for labels, maps, and outdoor applications requiring long-lasting visuals. Polypropylene printing provides excellent flexibility, moisture resistance, and cost-effectiveness, suitable for packaging, food labels, and promotional materials. Choosing between Mylar and polypropylene depends on the project's exposure conditions, budget, and desired aesthetic, with Mylar favored for strength and clarity, while polypropylene excels in versatility and affordability.

Mylar Printing vs Polypropylene Printing Infographic

materialdif.com

materialdif.com