Mylar sheets offer superior durability and resistance to moisture and chemicals compared to acetate sheets, making them ideal for long-lasting projects and archival purposes. Acetate sheets tend to be more flexible and easier to cut, but they are less resistant to environmental damage, which can lead to yellowing and degradation over time. Choosing Mylar sheets ensures enhanced clarity and stability, especially for pet-related applications requiring safe, non-toxic, and strong materials.

Table of Comparison

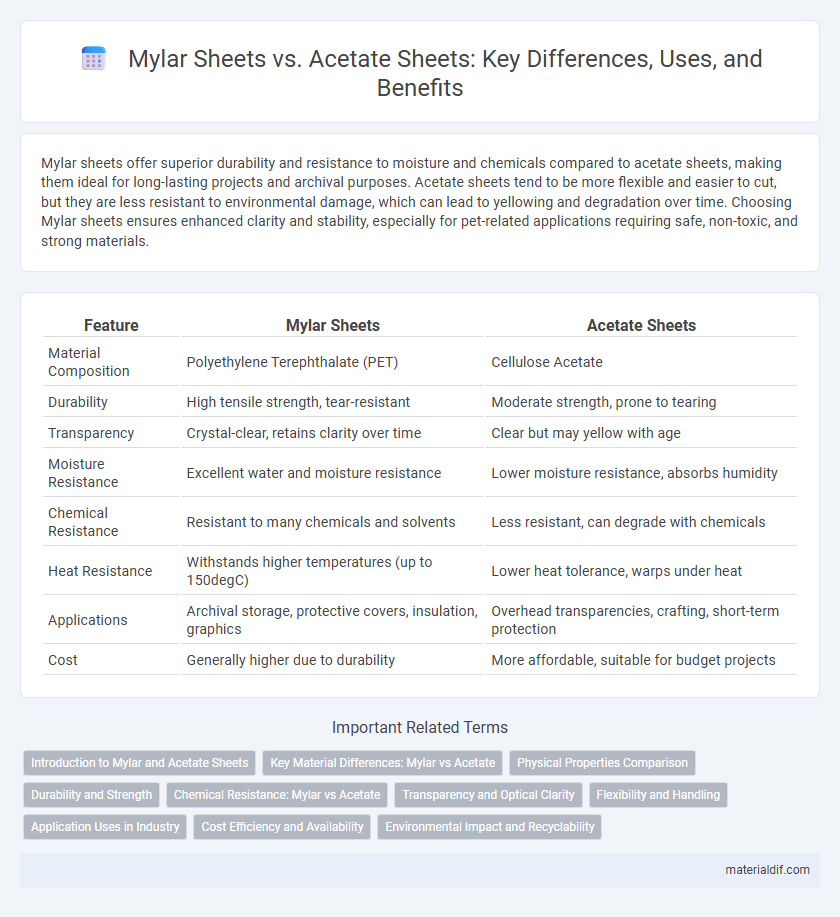

| Feature | Mylar Sheets | Acetate Sheets |

|---|---|---|

| Material Composition | Polyethylene Terephthalate (PET) | Cellulose Acetate |

| Durability | High tensile strength, tear-resistant | Moderate strength, prone to tearing |

| Transparency | Crystal-clear, retains clarity over time | Clear but may yellow with age |

| Moisture Resistance | Excellent water and moisture resistance | Lower moisture resistance, absorbs humidity |

| Chemical Resistance | Resistant to many chemicals and solvents | Less resistant, can degrade with chemicals |

| Heat Resistance | Withstands higher temperatures (up to 150degC) | Lower heat tolerance, warps under heat |

| Applications | Archival storage, protective covers, insulation, graphics | Overhead transparencies, crafting, short-term protection |

| Cost | Generally higher due to durability | More affordable, suitable for budget projects |

Introduction to Mylar and Acetate Sheets

Mylar sheets, made from biaxially-oriented polyethylene terephthalate (BoPET), offer superior strength, chemical stability, and clarity compared to acetate sheets, which are produced from cellulose acetate and tend to be less durable and more prone to yellowing over time. Mylar's dimensional stability and resistance to moisture make it ideal for archival storage, projection transparencies, and industrial applications, while acetate sheets are commonly used in craft projects and temporary overlays. The choice between Mylar and acetate sheets depends on the need for longevity, clarity, and environmental resistance in various professional and creative settings.

Key Material Differences: Mylar vs Acetate

Mylar sheets, made from stretched polyethylene terephthalate (PET), offer superior tensile strength, chemical resistance, and dimensional stability compared to acetate sheets, which are derived from cellulose acetate. Mylar's high clarity and resistance to moisture and temperature fluctuations make it ideal for durable, long-lasting applications, while acetate sheets are more prone to warping and yellowing over time. These material differences influence their suitability for uses ranging from industrial insulation to artistic overlays.

Physical Properties Comparison

Mylar sheets exhibit superior tensile strength and dimensional stability compared to acetate sheets, making them more resistant to stretching and deformation under stress. Mylar's higher melting point and resistance to moisture enhance its durability and longevity in various environmental conditions. Acetate sheets, while more flexible and easier to cut, tend to yellow and degrade faster when exposed to UV light and humidity.

Durability and Strength

Mylar sheets exhibit superior durability and strength compared to acetate sheets due to their polyester composition, which offers high tensile strength and resistance to tearing, moisture, and chemicals. Unlike acetate, Mylar maintains dimensional stability under temperature fluctuations and prolonged use, making it ideal for applications requiring long-lasting clarity and protection. These properties ensure Mylar sheets outperform acetate in demanding environments such as archival storage, lamination, and industrial packaging.

Chemical Resistance: Mylar vs Acetate

Mylar sheets exhibit superior chemical resistance compared to acetate sheets, making them ideal for applications involving exposure to solvents, oils, and various chemicals. Mylar, a polyester film, maintains structural integrity and resists degradation under harsh chemical conditions, unlike acetate, which tends to swell or warp. This enhanced chemical resistance ensures prolonged durability and reliability of Mylar in industrial, medical, and graphic arts settings.

Transparency and Optical Clarity

Mylar sheets offer superior transparency and optical clarity compared to acetate sheets, making them ideal for applications requiring high visual precision, such as overhead projections and protective covers. With a higher light transmittance rate, typically around 90-94%, Mylar provides clearer, crisper images without distortion. Acetate sheets tend to have lower clarity and may yellow or degrade over time, reducing their effectiveness in long-term or high-quality visual uses.

Flexibility and Handling

Mylar sheets offer superior flexibility and durability compared to acetate sheets, allowing for easier bending and manipulation without cracking or tearing. The polyester composition of Mylar provides enhanced resistance to moisture and temperature variations, making it more reliable for long-term handling and repeated use. Acetate sheets tend to become brittle over time, reducing their flexibility and increasing the risk of damage during handling.

Application Uses in Industry

Mylar sheets are preferred in industrial applications requiring high tensile strength, chemical resistance, and electrical insulation, making them ideal for electronics, packaging, and automotive industries. Acetate sheets, being less durable and more prone to moisture absorption, are primarily used for overhead projectors, photography, and lightweight packaging. The superior durability and dimensional stability of Mylar sheets allow for longer-lasting and more reliable performance in demanding industrial environments compared to acetate sheets.

Cost Efficiency and Availability

Mylar sheets offer superior cost efficiency compared to acetate sheets due to their durability and longer lifespan, reducing the need for frequent replacements. Mylar's widespread availability in various thicknesses and sizes makes it a more versatile choice for diverse applications, often at a lower price point. Acetate sheets, while less expensive upfront, tend to degrade faster, resulting in higher long-term costs and limited availability in specialized markets.

Environmental Impact and Recyclability

Mylar sheets, made from stretched polyethylene terephthalate (PET), offer superior environmental advantages over traditional acetate sheets due to their higher recyclability and durability, reducing waste in the long term. Acetate sheets tend to degrade more quickly and release volatile organic compounds (VOCs) during breakdown, posing greater environmental risks. Mylar's ability to be recycled repeatedly without significant loss of quality makes it a more sustainable option for various industrial and artistic applications.

Mylar Sheets vs Acetate Sheets Infographic

materialdif.com

materialdif.com